Fabrication method of flexible organic electroluminescence diode display

A manufacturing method and luminescent display technology, which are applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems affecting market promotion, difficult manufacturing process, low yield rate of large-area manufacturing, etc., and achieve simple replacement maintenance, Industrial operability and the effect of high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

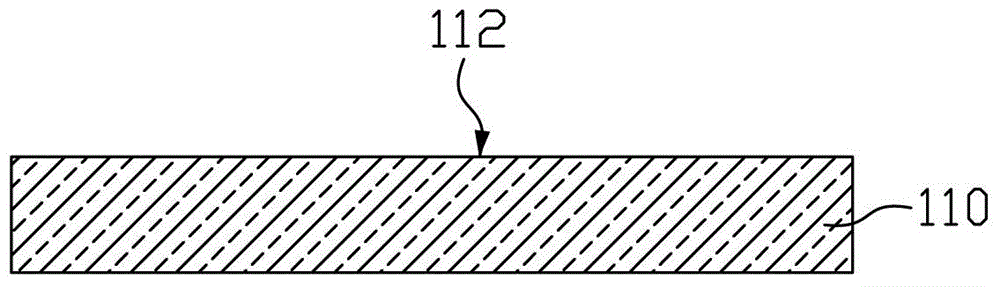

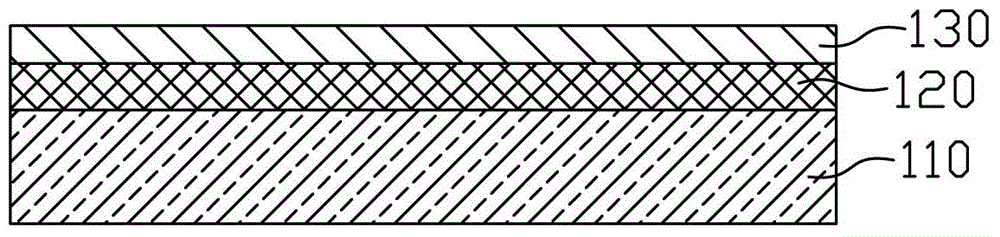

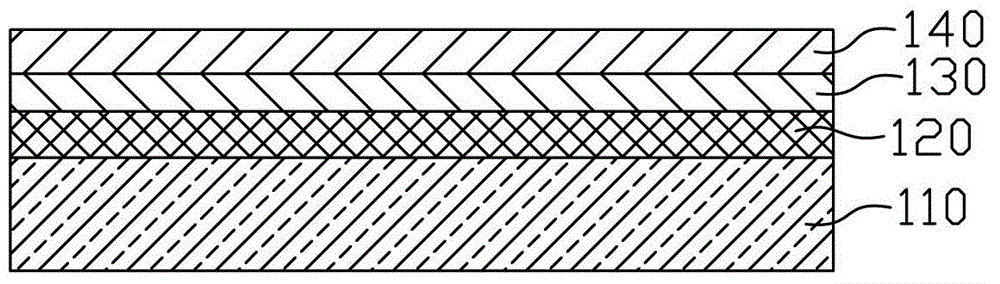

[0027] The embodiment of the present invention provides a manufacturing method of a flexible organic electroluminescent diode display. In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] The present invention proposes a method for manufacturing a flexible organic electroluminescent display (FOLED), and particularly relates to how to overlap flexible substrates, so as to realize the production of a large-size FOLED display from several small-size FOLED display units, that is, in the low-generation flexible The small-size FOLED display units of various shapes are first designed and fabricated on the substrate, and then the flexible substrates are overlapped by precise alignment to ensure the uniformity and consistency of the luminescent pixel arrangement required by the large-size display. The adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com