Valve pair sealability detection device and method

A sealing detection and valve pairing technology, which is applied in fluid tightness testing, measuring devices, liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problem of small swing range of pressure gauge pointer, lower pressure gauge reading, leakage To improve the accuracy of sealing detection and improve the quality of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

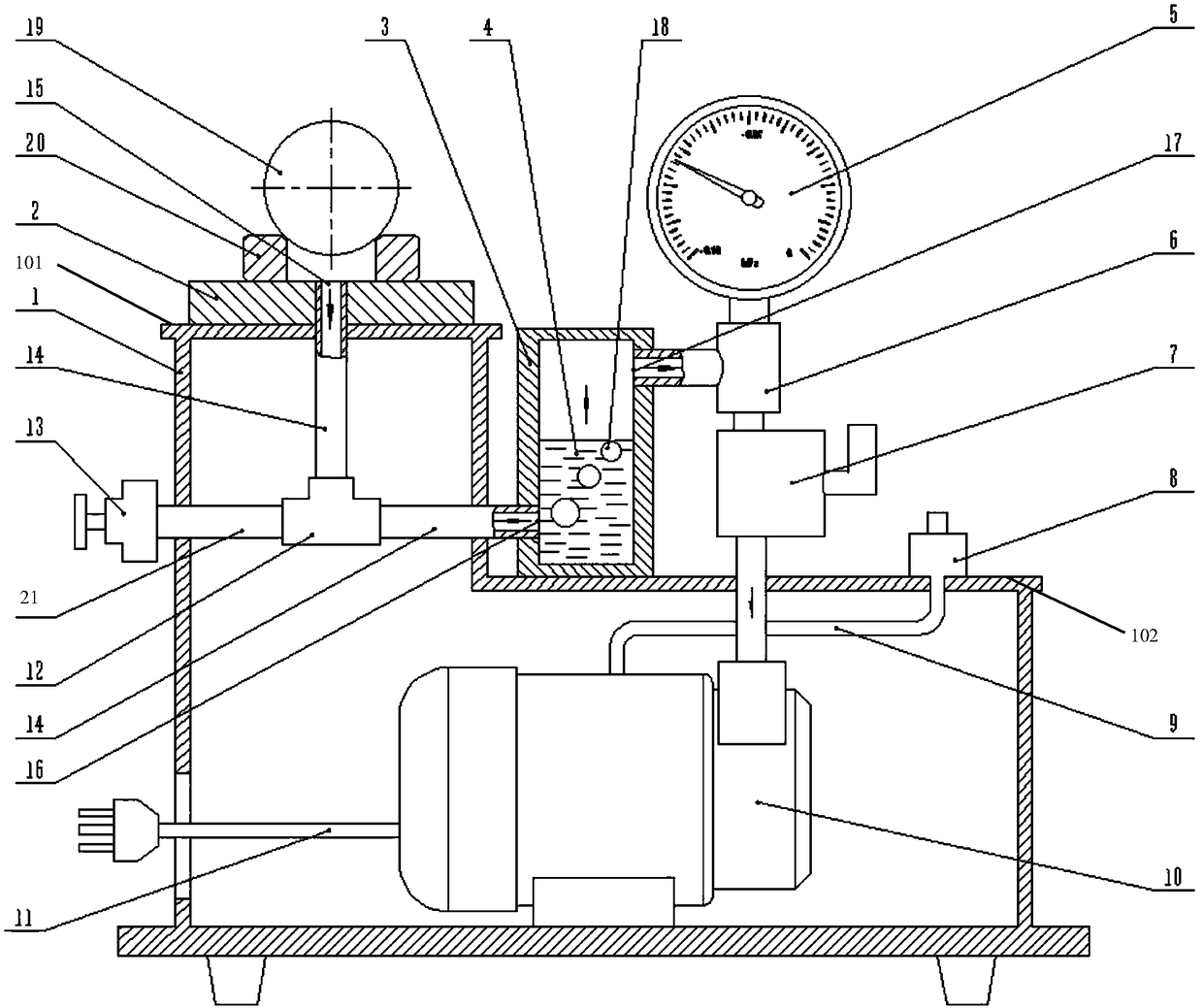

[0035] The valve pair leak detection device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] figure 1 It is a structural schematic diagram of the valve pair leak detection device of this embodiment. It shows a preferred embodiment of the valve pair leak detection device of the present invention.

[0037] Such as figure 1 As shown, a valve pair leak detection device includes a detection table 2 , a leakage observation chamber 3 , a vacuum pressure gauge 5 , a pressure maintaining valve 7 and a vacuum pump 10 .

[0038] The detection platform 2 communicates with the leakage observation chamber 3 through a pipeline 14 . Preferably, the leakage observation chamber 3 is a transparent sealed cylinder or a transparent square sealed box.

[0039] In the state of use, the tested valve pair formed by the valve ball 19 and the valve seat 20 is installed on the testing platform 2 and communicates with the pipeline 14 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com