Rail joint rail head eccentric loading-rail waist fatigue test device and test method

A technology of eccentric loading and fatigue testing, which is applied in the direction of measuring devices, testing of material strength by applying repetitive force/pulsation force, testing of mechanical components, etc., can solve problems such as rail waist fatigue, and achieve large fatigue load and easy disassembly The effect of loading and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

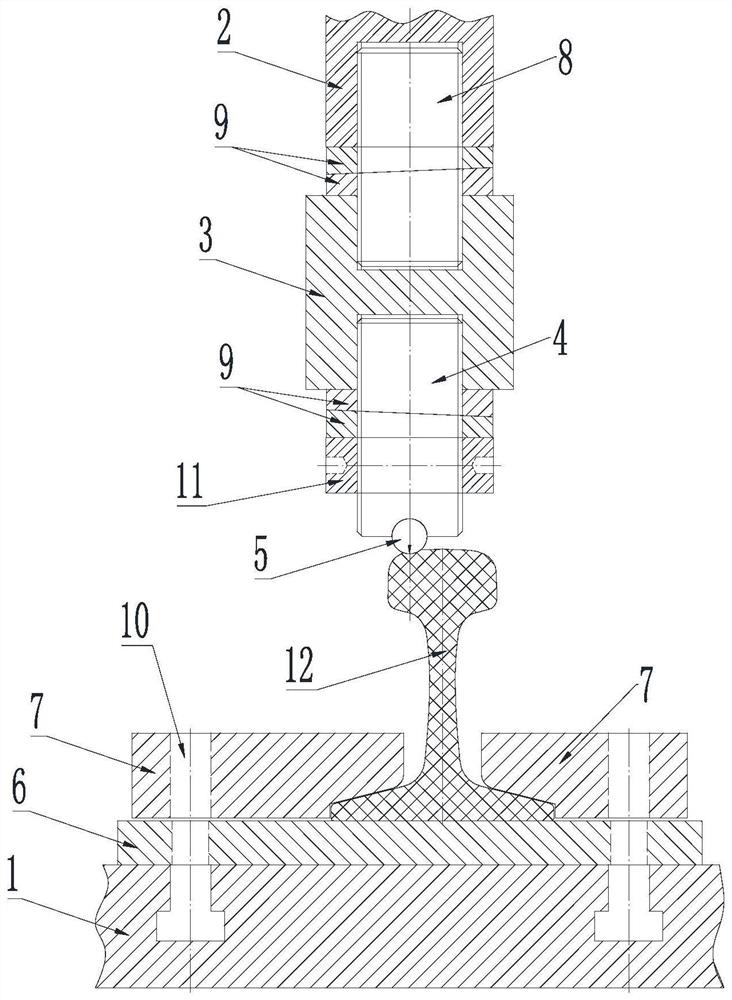

[0021] Such as figure 1 As shown, the rail joint rail head eccentric loading-rail waist fatigue test device of the present invention includes a hydraulic device, the hydraulic device includes a base 1 and a piston rod 2, the hydraulic device can be an electro-hydraulic servo machine or a pulsation fatigue testing machine, and the hydraulic device is a whole The main part of the test device. A lower supporting and fixing assembly is installed on the base 1 of the hydraulic device, and the lower supporting and fixing assembly is used for installing and fixing the steel rail 12 to be tested, and forms a support function for the steel rail 12 to be tested. The piston rod 2 of the hydraulic device is connected with an upper loading assembly, and the upper loading assembly is used to accurately apply an eccentric load to the rail head of the steel rail 12 to be tested.

[0022]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com