Safe operation device for quality inspection

A technology for safe operation and quality inspection, applied in the testing of measuring devices, instruments, mechanical parts, etc., can solve the problems of lowering the standard of testing, heavy weight, troublesome removal of half-shaft supports, etc., and achieves increased stability and simple structure. , the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

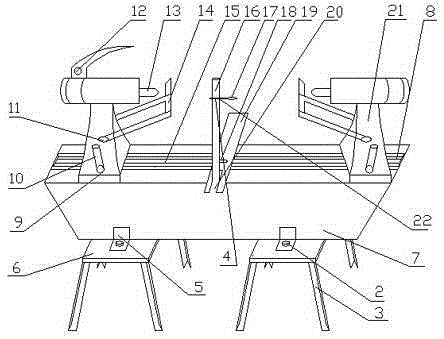

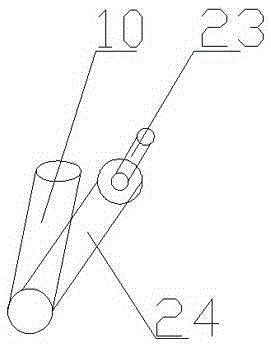

[0018] Example: see Figure 1-2 , a safety operating device for quality inspection, including a bracket 3, a fixed piece 5, a fixed plate 6, a fixed seat 7, a first quality inspection device 9, a rotating handle 10, an operating rod 14, a support rod 16, a fixed ring 17, and a slider 18 , cross bar 19 and second quality inspection device 21, described fixed seat 7 and fixed plate 6 are connected by fixed plate 5, and described fixed plate 5 is fixed on the fixed plate 6 by screw 2, and described fixed plate 6 lower ends are provided with Support 3, the upper end of the fixed seat 7 is provided with a groove 15, the two sides of the groove 15 are provided with slide rails 8, and the first quality inspection device 9 and the second quality inspection device 21 are installed in the groove 15 , the crossbar 19 is installed on the upper end of the groove 15 through the slider 18, and a hollow groove 20 is arranged on one side of the crossbar 19, and a support rod 16 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com