Automatic track spacing detection device and detection method

An automatic detection device and track spacing technology, which is applied in the direction of measuring devices, electromagnetic measuring devices, and electrical devices, can solve the problems of inability to provide accurate alarm prompts, fail to meet the use requirements, and low degree of automation, and achieve convenient track maintenance. , high degree of automation, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

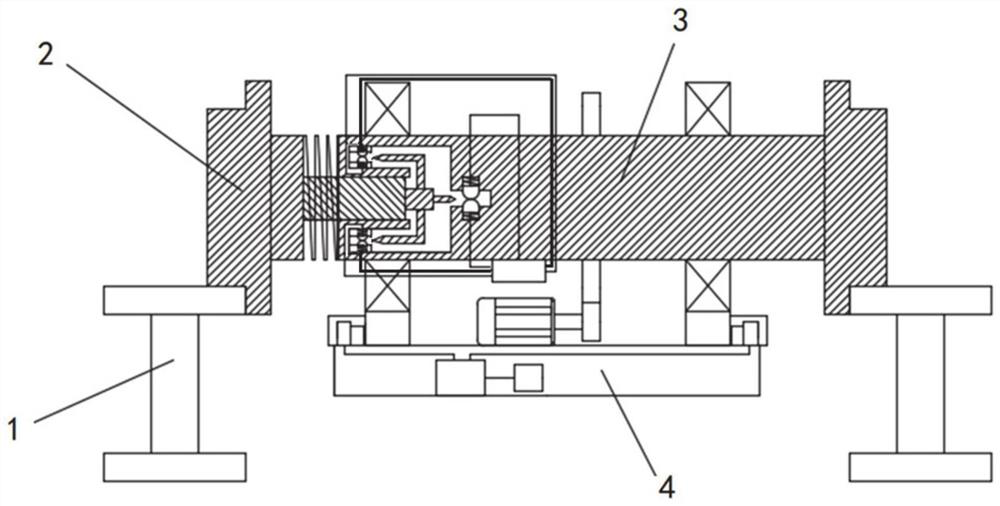

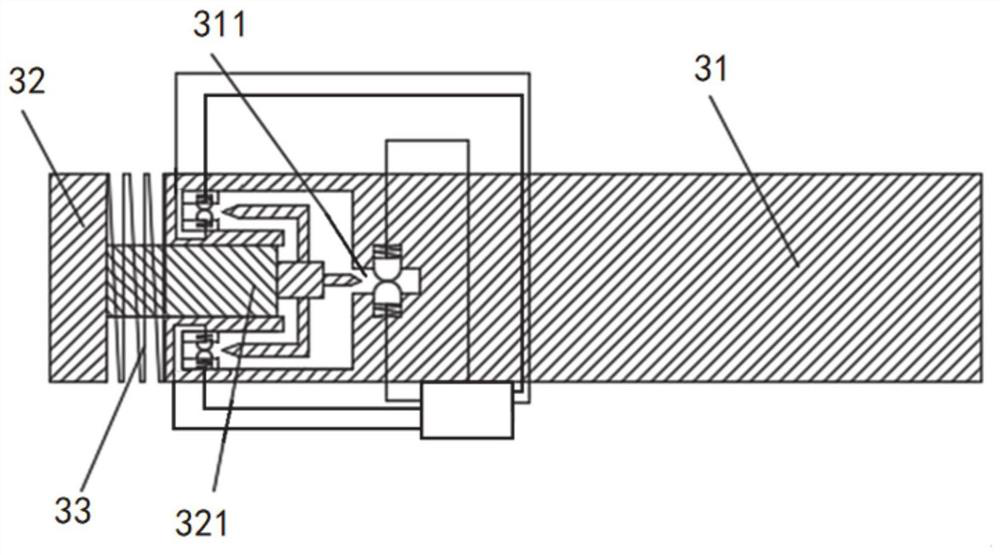

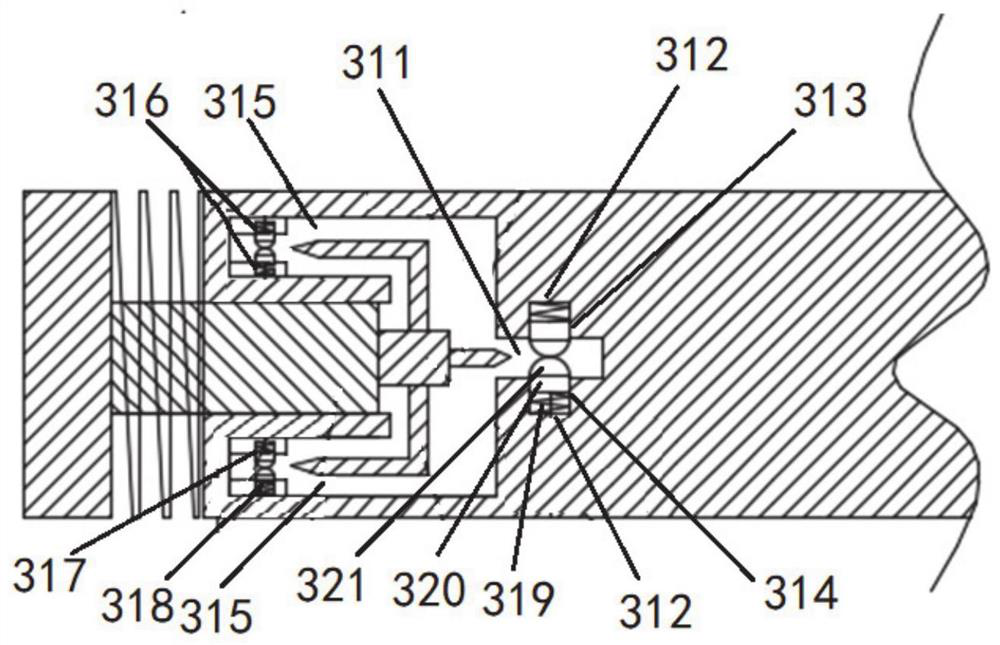

[0030] According to an embodiment of the present invention, an embodiment of an automatic track spacing monitoring device is provided, refer to Figure 1-Figure 5 , including: a driving shaft 3 and rollers 2 arranged at both ends of the driving shaft 3; the rollers 2 at both ends are respectively arranged on two I-shaped rails 1, and can move along the rails.

[0031] The lower side of drive shaft 3 is equipped with console 4, and console 4 is respectively provided with control unit 48, driving mechanism, positioning unit and image acquisition unit; Control unit 48 is connected with driving mechanism, positioning unit and image acquisition unit respectively; Positioning The unit and the image acquisition unit are used to realize the position positioning and image acquisition of the detected track, and upload the collected data to the control unit 48, record the data, and facilitate maintenance; the entire track spacing automatic monitoring device is compact in structure, high i...

Embodiment 2

[0051] According to an embodiment of the present invention, an embodiment of an automatic track spacing detection method is disclosed. The method is implemented based on the track spacing automatic monitoring device in Embodiment 1, and specifically includes the following process:

[0052] When the track spacing automatic monitoring device works normally, the driving shaft 3 drives the roller 2 to roll along the two track bodies;

[0053] When the distance between the two tracks is reduced, the roller 2 is squeezed, the first spring 33 is compressed, and the distance between the first shaft body and the second shaft body is reduced;

[0054] The first insulating insertion rod 323 is inserted between the first conductive member 313 and the second conductive member 314, so that the first conductive member 313 and the second conductive member 314 are disconnected, an alarm is triggered, and an alarm position is located and an image is collected at the same time.

[0055] When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com