Sealing ring assembly production line of clamping-pressing type pipe fitting

A technology for assembling production lines and pressing pipe fittings, which is applied in assembly machines, measuring devices, measuring fluid pressure, etc., can solve the problems of large quality differences of pipe fittings, high product failure rate, increase production costs, etc., and save labor costs. , The effect of improving the accuracy of the transfer and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

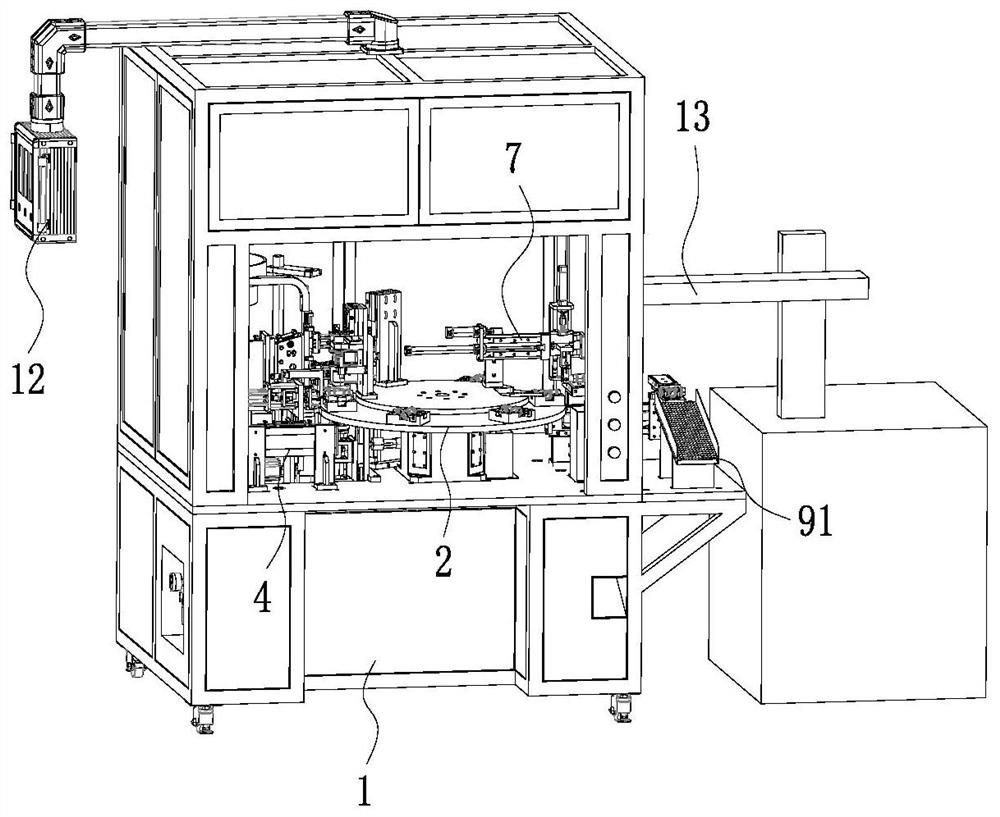

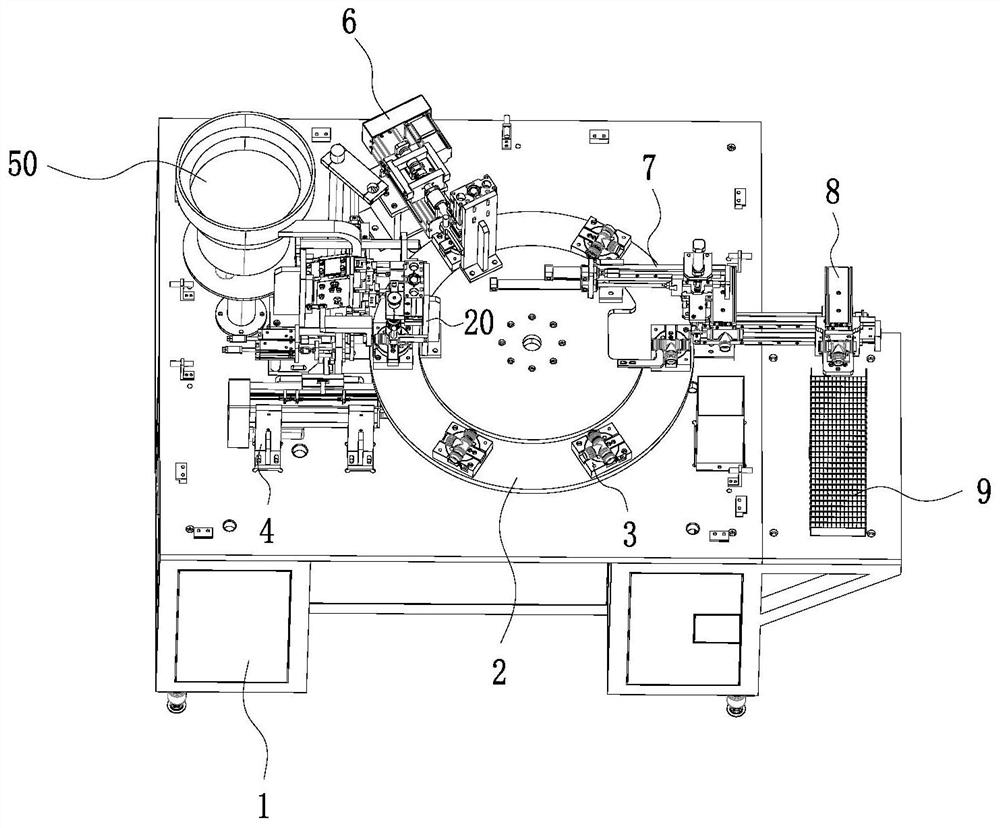

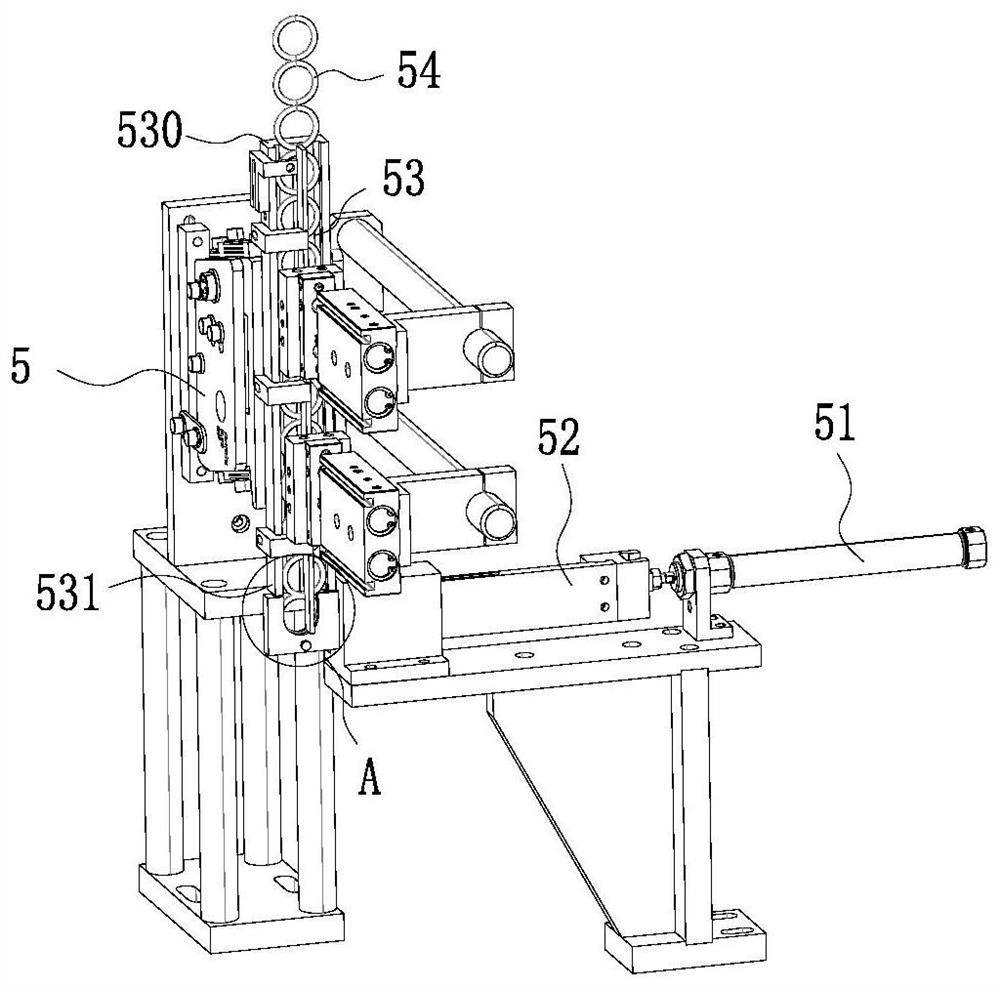

[0050] Such as Figure 1 to Figure 16 As shown, this embodiment shows a sealing ring assembly production line for compression-type pipe fittings, including a turntable 2, an assembly station, a detection station, a reclaiming station, a marking and sorting station and a controller 12. The assembly station, detection station, material retrieving station, and marking and sorting station are arranged along the circumference of the turntable 2. This embodiment is installed on the support table 1, and the turntable 2 is provided with a first driver and 6 In the pipe fitting station 3 where the pipe fitting 33 to be processed is placed, the first driver is used to control the rotation of the turntable 2 to make the pipe fitting station 3 sequentially pass through the assembly station, the detection station, and the pick-up station; the assembly station includes a feeding station device 5 and feeding device 4, the feeding device 5 is used to transport the sealing ring 54 to the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com