Preparation method of N-standard sample suitable for electron probe analysis

An electronic probe, standard sample technology, applied in the direction of using wave/particle radiation for material analysis, analysis of materials, measurement devices, etc. problem, to achieve the effect of improving accuracy and good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing an N-standard sample suitable for electron probe analysis, which includes preparing Fe-N alloy samples with different N contents and detecting the prepared standard sample. Specifically include:

[0039] S1. With Fe micropowder and Fe-N compound (the main constituent phase is Fe 4 N or Fe 3 N 1.3 , containing a small amount of Fe) micropowder as raw material, weighing, ball milling and drying according to different N content ratios, to obtain a mixed powder with a mass fraction of N of 0.5-2.0wt.%; 4 N and Fe 3 N 1.3 The compound is used as the starting material, and it is bottled for later use after being dried. Wherein, the N content in the Fe-N compound is determined in advance by using an oxygen, nitrogen and hydrogen combined detector (equipment model: Leco, ONH836).

[0040] The specific method of mixing powder with N content of 0.5-2.0wt.% is as follows: according to the mass fraction of the required standard sa...

Embodiment 1

[0059] The present embodiment provides the N-standard sample whose N content is 0.5-2.0wt%, and its preparation method comprises the following steps:

[0060] Choose Fe powder and Fe 4 N powder is mixed, wherein the N content is set to 0.5, 1.0, 1.5 and 2.0wt% in turn; about Fe 4 For N powder, use an oxygen, nitrogen and hydrogen combined detector (equipment model: Leco, ONH836) to determine the N content in it in advance, and use this as a basis to carry out the above powder mixing scheme.

[0061] Mixed powders with different N contents were ball milled and mixed with absolute alcohol as a dispersant for at least 10 hours, and then placed in a vacuum drying oven with a beaker holder for drying. The drying temperature was set at 100°C for 3 hours. The powders of different components are each 50g after drying.

[0062] Put the dried powders of each component into the mold respectively, use a powder press machine to shape it, seal the sample with a metal molybdenum container,...

Embodiment 2

[0067] This example provides Fe 4 The N-standard sample of N as main phase, its preparation method comprises the following steps:

[0068] Among the embodiment 1, use the oxygen, nitrogen and hydrogen combined detector to detect (equipment model: Leco, ONH836) to determine the content of N in the form of Fe 4 The N-based powder was fully dried in a vacuum oven for 3 hours at a drying temperature of 100°C. Then put it in a mold, use a powder tablet press to shape it, and seal it with a metal molybdenum container, then put it in a dry box for high-pressure sintering. Wherein, the original sample is a cylindrical sample with a diameter of 11-14 mm and a thickness of 1 mm-3.5 mm.

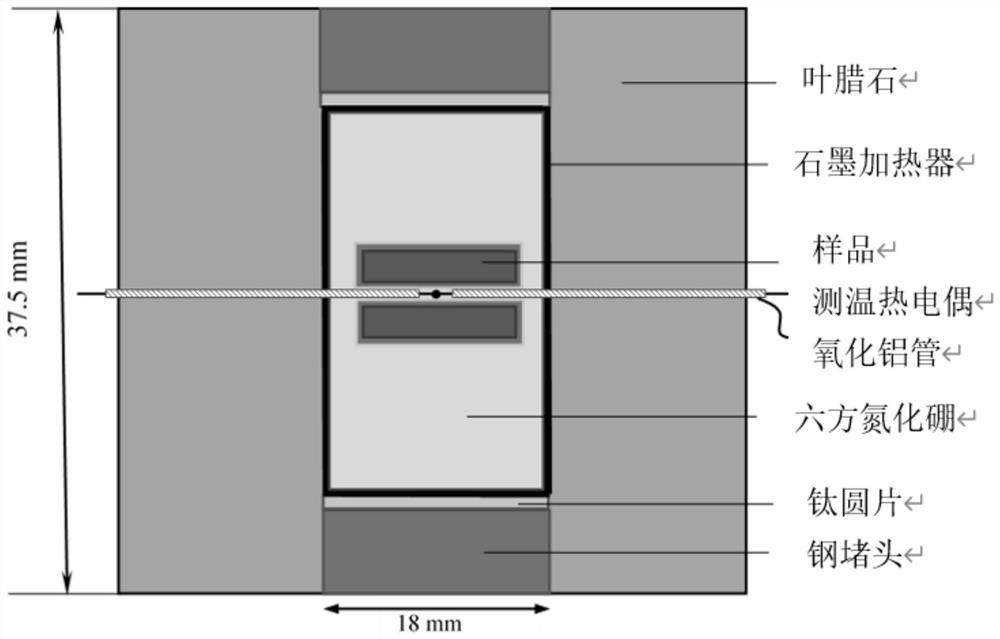

[0069] Put the sealed tablet into a six-sided top large chamber press for high-temperature sintering. Among them, the temperature and pressure of the six-sided top chamber are set to 1100°C and 5GPa. The holding time is 1 hour.

[0070] The samples were polished sequentially on 400, 800, 1500, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com