Gypsum self-leveling mortar for floor heating backfilling and preparation method of gypsum self-leveling mortar

A self-leveling mortar and gypsum technology, applied in the field of building materials, can solve the problems of not conforming to the green and low energy consumption development concept, requiring mechanical equipment and site support, unfavorable promotion and utilization, etc. , The effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

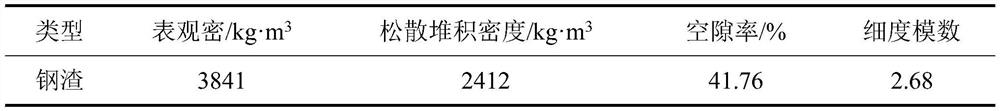

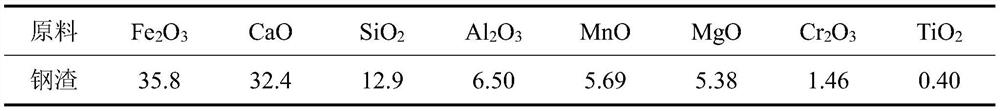

Image

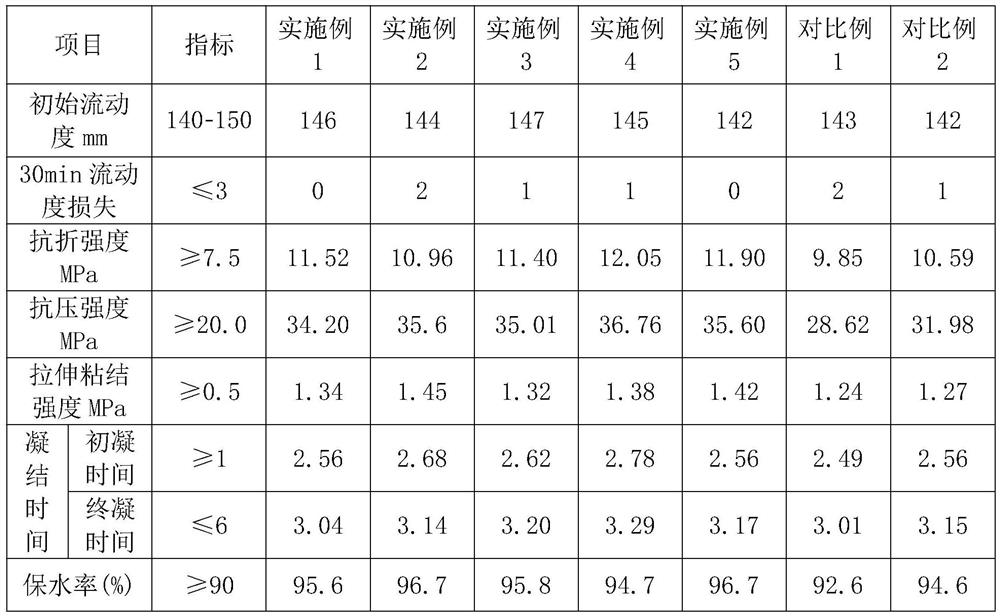

Examples

Embodiment 1

[0029] A gypsum self-leveling mortar used for floor heating backfill, comprising the following components in parts by weight:

[0030] Phosphogypsum powder (β-hemihydrate gypsum) 420 parts, electric furnace air-cooled steel slag 110 parts, cement (PⅡ52.5 cement) 60 parts, graphite powder (600 mesh) 24 parts, calcium oxide 8 parts, aluminum magnesium silicate 8 parts , 0.5 parts of gypsum retarder, 0.7 parts of polycarboxylate superplasticizer, 10 parts of VAE redispersible rubber powder, 3 parts of defoamer, and 200 parts of water.

[0031] Preparation method of gypsum self-leveling mortar:

[0032] Put gypsum powder, cement, graphite powder, calcium oxide, aluminum magnesium silicate, gypsum retarder, water reducer, redispersible latex powder and defoamer into the mortar mixer, and mix at a low speed of 65r / min 2-5min, then add steel slag and water, continue mixing and stirring at 125r / min high-speed speed for 2-5min, that is.

Embodiment 2

[0034] A gypsum self-leveling mortar used for floor heating backfill, comprising the following components in parts by weight:

[0035] Phosphogypsum powder (β-hemihydrate gypsum) 450 parts, electric furnace air-cooled steel slag 120 parts, cement (PⅡ52.5 cement) 50 parts, graphite powder (600 mesh) 26 parts, calcium oxide 12 parts, aluminum magnesium silicate 6 parts , 0.6 parts of gypsum retarder, 0.6 parts of polycarboxylate superplasticizer, 11 parts of VAE redispersible rubber powder, 3.5 parts of defoamer, and 210 parts of water.

[0036] Preparation method of gypsum self-leveling mortar:

[0037] Put gypsum powder, cement, graphite powder, calcium oxide, aluminum magnesium silicate, gypsum retarder, water reducer, redispersible latex powder and defoamer into the mortar mixer, and mix at a low speed of 65r / min 2-5min, then add steel slag and water, continue mixing and stirring at 125r / min high-speed speed for 2-5min, that is.

Embodiment 3

[0039] A gypsum self-leveling mortar used for floor heating backfill, comprising the following components in parts by weight:

[0040] Phosphogypsum powder (β-hemihydrate gypsum) 430 parts, electric furnace air-cooled steel slag 125 parts, cement (PⅡ52.5 cement) 40 parts, graphite powder (600 mesh) 27 parts, calcium oxide 11 parts, aluminum magnesium silicate 9 parts , 0.6 parts of gypsum retarder, 0.6 parts of polycarboxylate superplasticizer, 12 parts of VAE redispersible rubber powder, 3.5 parts of defoamer, and 215 parts of water.

[0041] Preparation method of gypsum self-leveling mortar:

[0042] Put gypsum powder, cement, graphite powder, calcium oxide, aluminum magnesium silicate, gypsum retarder, water reducer, redispersible latex powder and defoamer into the mortar mixer, and mix at a low speed of 65r / min 2-5min, then add steel slag and water, continue mixing and stirring at 125r / min high-speed speed for 2-5min, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com