Elastic texture paint and preparation method thereof

A textured coating and elasticity technology, applied in the coating and other directions, can solve the problems of oil-water separation, heavy specific gravity, sinking of pigments and fillers, etc., to achieve the effect of strong texture, different styles and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A kind of elastic texture paint, it comprises the following parts by weight to make:

[0072] water 6;

[0073] Anti-mildew and anti-algae agent 0.1;

[0074] Preservatives 0.06;

[0075] Dispersant 0.1;

[0076] Wetting agent 0.06;

[0077] 600 mesh heavy calcium powder 7;

[0078] Titanium dioxide 5;

[0079] Magnesium aluminum silicate 0.6;

[0081] Microsilica 2.0;

[0082] First Emulsion 11;

[0083] Second emulsion 16;

[0084] 16-30 mesh stone grains 18;

[0085] 30-60 mesh stone grains 17;

[0086] 60-80 mesh stone particles 9;

[0087] Defoamer 0.08;

[0088] The first solvent 0.6;

[0089] Second solvent 1.5;

[0090] Cellulose 0.3;

[0091] Thickener 0.3;

[0092] pH adjustment agent 0.06.

Embodiment 2

[0094] A kind of elastic texture paint, it comprises the following parts by weight to make:

[0095] water 9;

[0096] Anti-mildew and anti-algae agent 0.3;

[0097] Preservatives 0.14;

[0098] Dispersant 0.3;

[0099] Wetting agent 0.14;

[0100] 600 mesh heavy calcium powder 11.0;

[0101] Titanium dioxide 9.0;

[0102] Magnesium Aluminum Silicate 2.0;

[0104] Silica powder 8.0;

[0105] First Emulsion 14;

[0106] Second lotion 19;

[0107] 16-30 mesh stone grains 21;

[0108] 30-60 mesh stone grains 34;

[0109] 60-80 mesh stone grains 14;

[0110] Defoamer 0.21;

[0111] First solvent 1.4;

[0112] Second solvent 3.0;

[0113] Cellulose 0.8;

[0114] Thickener 3.4;

[0115] pH adjustment agent 2.4.

Embodiment 3

[0117] A kind of elastic texture paint, it comprises the following parts by weight to make:

[0118] water 5-10;

[0119] Anti-mildew and anti-algae agent 0.1-0.3;

[0120] Preservatives 0.05-0.15;

[0121] Dispersant 0.1-0.3;

[0122] Wetting agent 0.05-0.15;

[0123] 600 mesh heavy calcium powder 6.5-11.5;

[0124] Titanium dioxide 4.0-10.0;

[0125] Magnesium aluminum silicate 0.5-2.0;

[0126] Sepiolite wool 0.1-0.5;

[0127] Silica powder 1.0-8.5;

[0128] 1st lotion 10-15;

[0129] Second lotion 15-20;

[0130] 16-30 mesh stone 18-22;

[0131] 30-60 mesh stone 16-35;

[0132] 60-80 mesh stone 8-15;

[0133] Defoamer 0.10-0.18;

[0134] The first solvent 0.5-1.5;

[0135] Second solvent 1.0-3.0;

[0136] Cellulose 0.2-0.9;

[0137] Thickener 0.2-3.6;

[0138] pH adjustment agent 0.05-2.5.

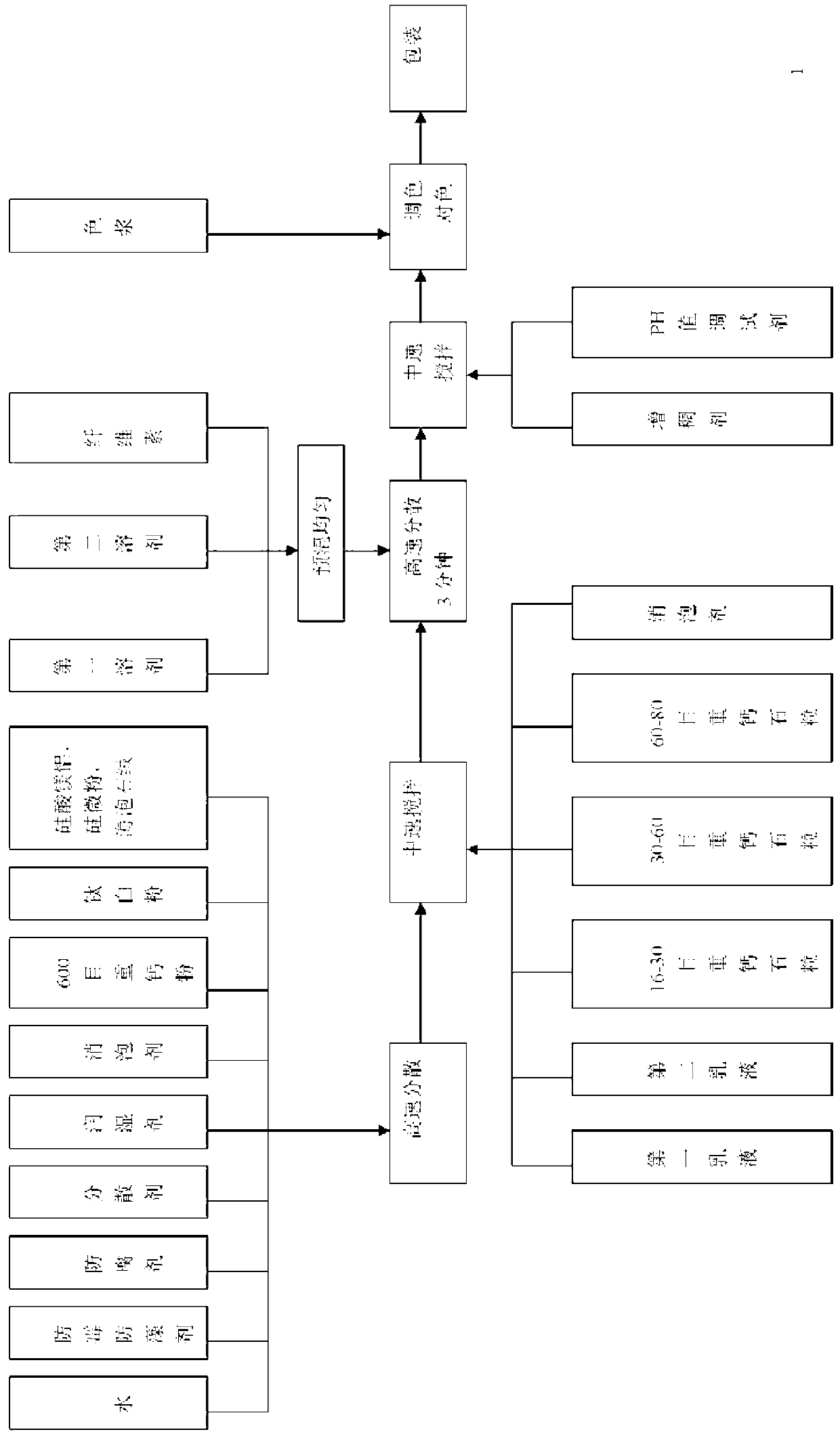

[0139] The preparation method of above-mentioned elastic texture coating, such as figure 1 As shown, it includes the following steps:

[0140] (1) Add 1 / 3-1 / 2 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com