Thickening time control agent used for gypsum mortar, and preparation method thereof

A technology of gypsum mortar and coagulation regulator, which is applied in the field of gypsum mortar admixture, can solve problems such as unfavorable construction operations, and achieve the effect of convenient preparation and application and simple mortar ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, a kind of gypsum mortar coagulant, it is made up of the composition of following weight content:

[0035] Anhydrous citric acid 25%, anhydrous sodium pyrophosphate 20%, hydroxypropyl methylcellulose ether (HPMC) 7.5%, sodium tripolyphosphate 5%, pregelatinized starch (modified starch) 10%, sodium base Bentonite 20%, polycarboxylate superplasticizer 10%, inorganic magnesium aluminum silicate gel 2.5%.

[0036] Its preparation method is:

[0037] 1) Put sodium-based bentonite in a heating container and heat to 50-60°C, add hydroxypropyl methylcellulose ether (HPMC) and blend evenly, so as to achieve graft modification of sodium-based bentonite and obtain water-retaining bentonite Modified powder;

[0038] 2) Water-retaining bentonite modified powder, anhydrous citric acid, anhydrous sodium pyrophosphate, sodium tripolyphosphate, pregelatinized starch (modified starch), polycarboxylate superplasticizer and inorganic magnesium aluminum silicate The gel is u...

Embodiment 2

[0039] Embodiment 2, a kind of gypsum mortar coagulation regulator, it is made up of the composition of following weight content:

[0040] Anhydrous citric acid 26.7%, anhydrous sodium pyrophosphate 18%, hydroxypropyl methylcellulose ether (HPMC) 7%, sodium tripolyphosphate 4.5%, pregelatinized starch (modified starch) 10.8%, sodium base Bentonite 21.8%, polycarboxylate superplasticizer 9%, inorganic magnesium aluminum silicate gel 2.2%.

[0041] The preparation method is identical to Example 1.

Embodiment 3

[0042] Embodiment 3, a kind of gypsum mortar coagulant, it is made up of the composition of following weight content:

[0043] Anhydrous citric acid 23.2%, anhydrous sodium pyrophosphate 22%, hydroxypropyl methyl cellulose ether (HPMC) 8%, sodium tripolyphosphate 5.5%, pregelatinized starch (modified starch) 9.2%, sodium base Bentonite 18.3%, polycarboxylate superplasticizer 11%, inorganic magnesium aluminum silicate gel 2.8%.

[0044] The preparation method is identical to Example 1.

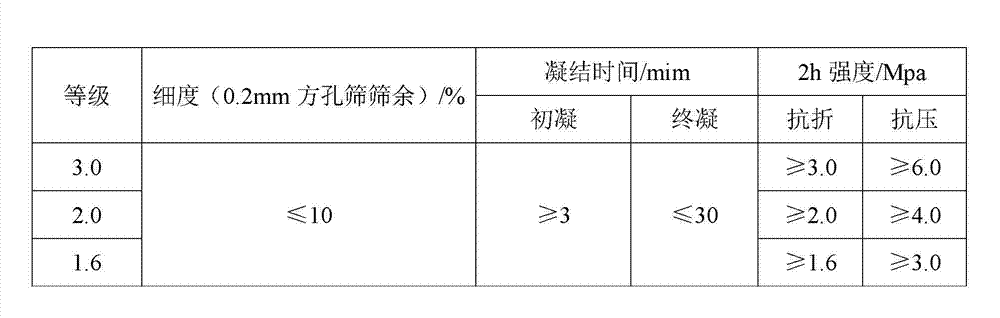

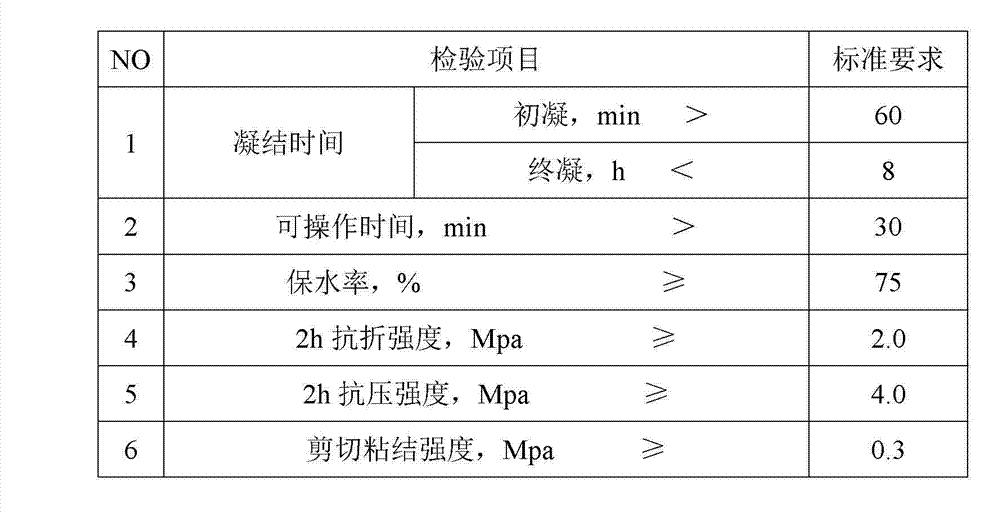

[0045] In order to verify the performance of the present invention, the inventor did an experimental test on the gypsum mortar coagulation agent (taking the proportion of gypsum mortar for plastering the bottom layer of M4.0 interior wall plastering as an example), and the results are as follows:

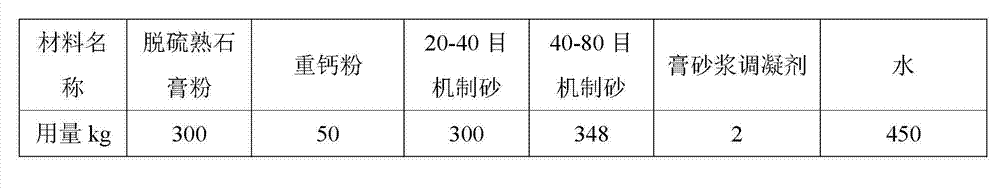

[0046]1. Raw materials and admixtures for testing

[0047] 1. Desulfurization plaster powder

[0048] 2. Heavy calcium powder

[0049] 3. 20-40 mesh machine-made sand

[0050] 4. 40-80 mesh mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com