Two-component efficient and light internal wall insulation putty and preparation method thereof

A thermal insulation putty, a two-component technology, applied in the direction of fireproof coatings, filling slurry, etc., can solve the problems of poor thermal insulation effect, high thermal conductivity, poor thermal insulation performance, etc., and achieve the characteristics of not easy to crack, high bonding strength and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method comprises the following steps:

[0036] 1) Take 35kg of water, add 0.3kg of film-forming aid and 0.5kg of cellulose to the water under agitation at 300rpm, then stir at 300rpm for 10min, then stir at 800rpm for 30min;

[0037] 2) Add 15kg of hydrophobic magnesium aluminum silicate and 10kg of hydrophobic SiO in sequence 2 Airgel, 18kg of rock wool, 0.1kg of retarder and 5kg of bentonite were stirred at 800rpm for 60min, then 3kg of synthetic resin emulsion was added under stirring at 300rpm, and the stirring was continued for 10min to obtain component 2;

[0038] 3) When in use, take 48kg of component 1 gypsum and add it to component 2 under stirring, and stir to form a paste to obtain the finished product.

Embodiment 1

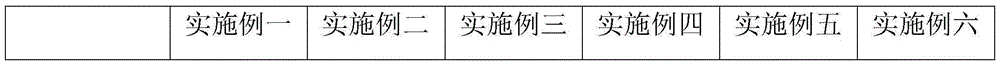

[0039] Embodiment 1, embodiment 2, the step of the preparation method of embodiment 4, embodiment 5 and embodiment 6 except the quality of each component of table 1 is different, all the other are consistent with embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com