Machine-spraying light-weight plastering mortar and preparation method thereof

A light-weight, heat-retaining mortar technology, applied in the field of mortar, can solve the problems of high aggregate density, easy to block nozzles, and poor surface quality, and achieve the effects of low density, improved comfort, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

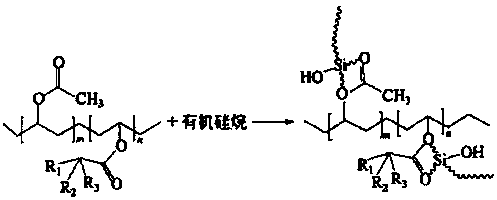

Method used

Image

Examples

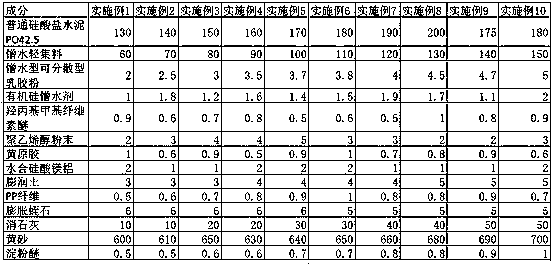

Embodiment 1- Embodiment 10

[0046] Embodiment 1-embodiment 10 is prepared through the following steps:

[0047] A preparation method for preparing lightweight thermal insulation mortar, comprising the following steps:

[0048] Step 1. Premixing: Ordinary Portland cement, slaked lime, hydrophobic redispersible latex powder, water repellent, polyvinyl alcohol powder, hydrated magnesium aluminum silicate, bentonite, starch ether, hydroxypropyl methylcellulose Put the plain ether into the mortar mixing equipment and stir until uniform, the rotating speed of the mixing equipment is 24r / min, and the mixing time of the mixing equipment is 4 minutes to 7 minutes;

[0049] Step 2. Mixing of finished materials: Mix the pre-mixed materials with yellow sand, hydrophobic light aggregate, expanded vermiculite, and PP fiber until uniform. The speed of the mixing equipment is 24r / min, and the mixing time of the mixing equipment is less than 5 minutes.

Embodiment 1 to Embodiment 10

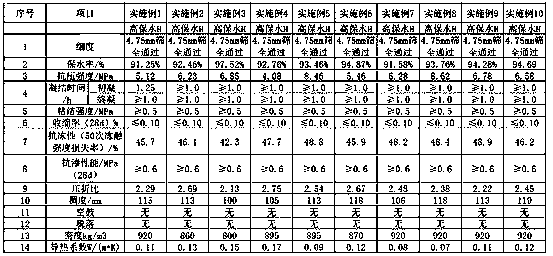

[0052] Embodiment 1 to Embodiment 10 are based on JG / T 291-2011 "Masonry and Plastering Dry-Mixed Mortar for Buildings" standard, and the machine spraying construction of Embodiment 1 to Embodiment 10 is based on JGJ-T105-2011 "Mechanical Spraying and Plastering". According to the standard construction of Construction Regulations, the test results are shown in the table below:

[0053]

[0054] In fact, it can be seen from the test results that the number of parts of yellow sand is 650 parts, the number of parts of hydrophobic redispersible latex powder is 3 parts, and the proportion of PP fiber is 0.7 parts. The overall quality of the plaster is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com