Waterborne ultralow-VOC-content high-weatherability real stone paint and preparation method thereof

A real stone paint, ultra-low technology, applied in the field of coatings, can solve the problems of lack of production technology, unstable quality, poor performance, etc., achieve excellent construction smoothness, improve construction smoothness, and reduce the effect of sand loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

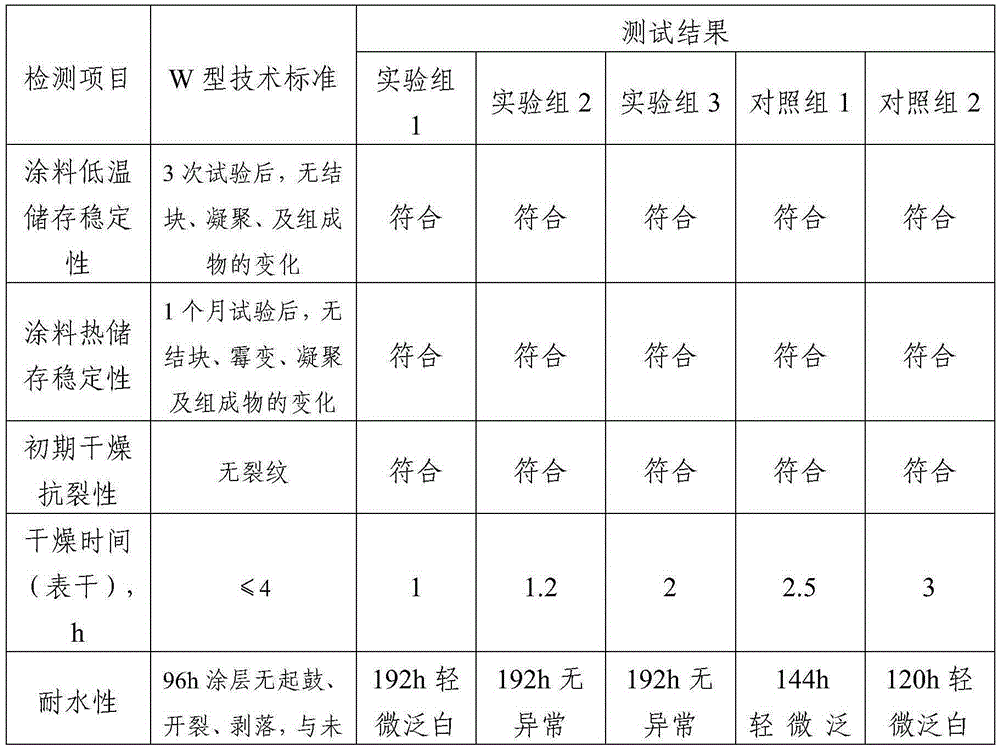

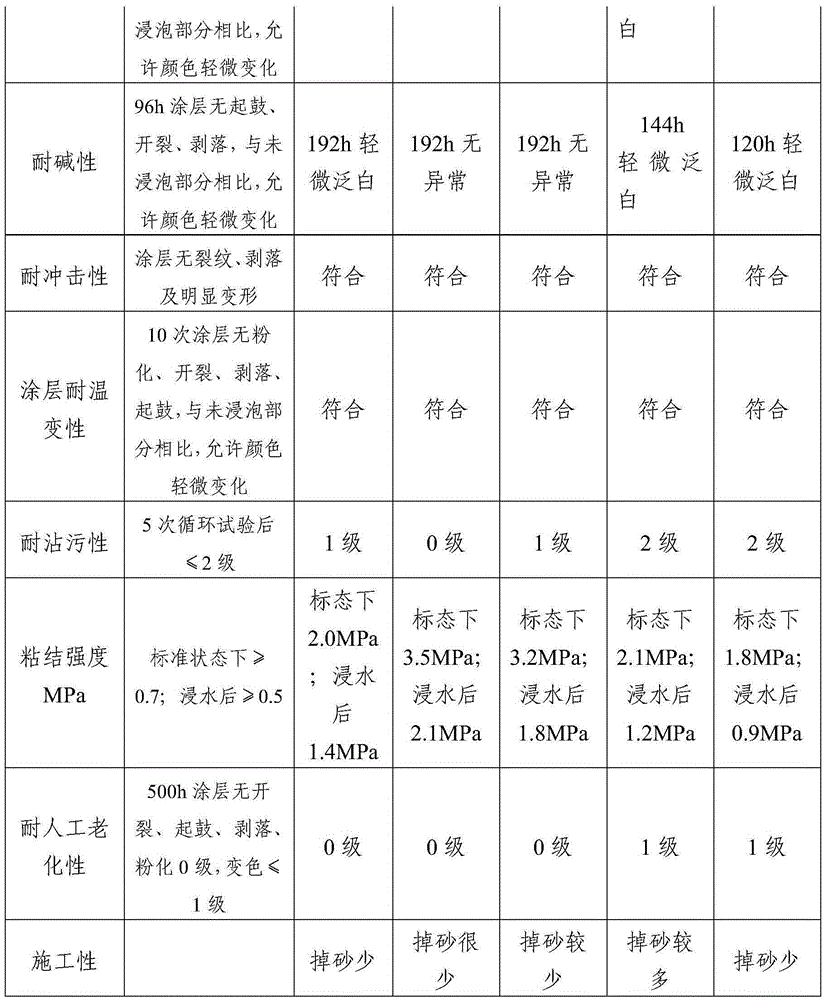

Examples

Embodiment 1

[0028] This embodiment provides a water-based ultra-low VOC high-weather-resistant real stone paint, which is prepared from raw materials including the following components in parts by weight: 9 parts of pure acrylic emulsion, 4 parts of silica sol , 0.2 parts of compatible stabilizers, 9 parts of deionized water, 0.2 parts of cellulose, 0.1 parts of defoamers, 0.1 parts of preservatives, 1 part of antifreeze, 0.6 parts of film-forming aids, 65 parts of sintered colored sand, 0.8 parts Magnesium aluminum silicate and 0.3 part of thickening agent, using a pH regulator to adjust the pH value of the real stone paint to 8-10.

[0029] Wherein, the pure acrylic emulsion is AC-261P of Rohm and Haas, and the silica sol is CH83-130 of Jiangsu Guolian; the compatible stabilizer is preferably sodium lauryl sulfate; The HE-10K of Kualong; The defoamer is the SN-154 of Nopco; The pH regulator is the 2-amino-2-methyl-1-propanol AMP-95 of Dow Chemical; The preservative is the HF of Sol; th...

Embodiment 2

[0031] This embodiment provides a water-based ultra-low VOC high-weather-resistant real stone paint, which is prepared from raw materials comprising the following components in parts by weight: 11 parts of pure acrylic emulsion, 6 parts of silica sol , 0.3 parts of compatible stabilizer, 11 parts of deionized water, 0.25 parts of cellulose, 0.3 parts of defoamer, 0.2 parts of preservatives, 1.5 parts of antifreeze, 0.8 parts of film-forming aids, 75 parts of sintered colored sand, 1.0 parts Magnesium aluminum silicate and 0.5 part of thickener, using a pH regulator to adjust the pH value of the real stone paint to 8-10.

[0032] Wherein, the pure acrylic emulsion is AC-261P of Rohm and Haas, and the silica sol is CH83-130 of Jiangsu Guolian; the compatible stabilizer is preferably sodium lauryl sulfate; The HE-10K of Kualong; The defoamer is SN-154 of Nopco; The pH regulator is Butylethanolamine Evander; The preservative is Sol’s EPW; The antifreeze is Tao The propylene glyco...

Embodiment 3

[0034] This embodiment provides a water-based ultra-low VOC high-weather-resistant real stone paint, which is prepared from raw materials including the following components in parts by weight: 10 parts of pure acrylic emulsion, 5 parts of silica sol , 0.25 parts of compatible stabilizers, 10 parts of deionized water, 0.22 parts of cellulose, 0.2 parts of defoamers, 0.25 parts of defoamers, 0.15 parts of preservatives, 12 parts of antifreeze, 0.7 parts of film-forming aids, 60 parts Sintered colored sand, 0.5 part of magnesium aluminum silicate and 0.1 part of thickener, using a pH regulator to adjust the pH value of the real stone paint to 8-10.

[0035] Wherein, the pure acrylic emulsion is AC-261P of Rohm and Haas, and the silica sol is CH83-130 of Jiangsu Guolian; the compatible stabilizer is preferably sodium lauryl sulfate; The HE-10K of Kualong; the defoamer is SN-154 of Nopco; the pH regulator is 2-amino-2-methyl-1-propanol AMP-95 and butyl ethanolamine Evander A mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com