Art texture water paint and preparation method thereof

An artistic and textured technology, applied in coatings, polyamide coatings, etc., can solve problems such as poor water resistance, poor construction, flexibility and poor initial water resistance, and achieve environmental protection requirements, excellent construction performance, and improved decorative performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

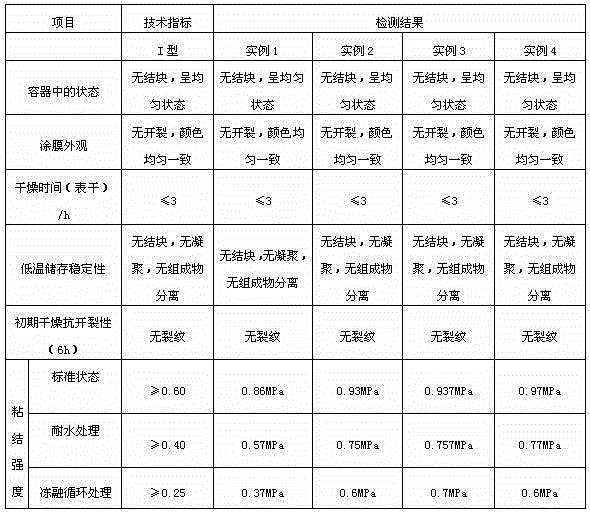

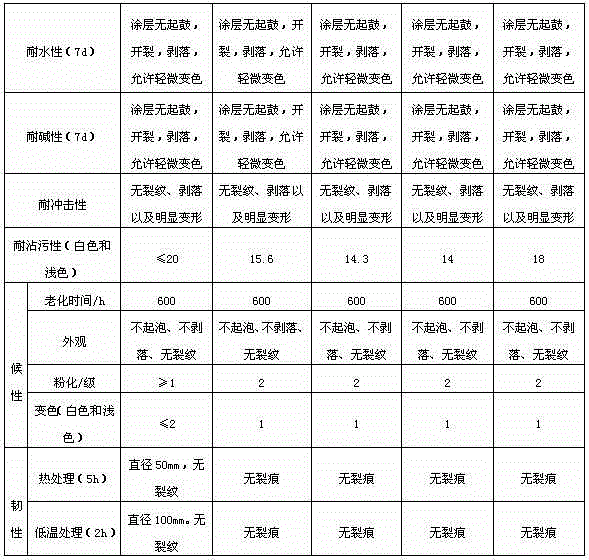

Examples

Embodiment 1

[0032] An artistic texture water paint, according to the proportion by weight, the components of the artistic texture water paint include:

[0033] 140 parts of pure acrylic elastic emulsion, 450 parts of 40-80 mesh round sand, 50 parts of 20-40 mesh texture round sand, 30 parts of polyamide wax solution, 50 parts of titanium dioxide, 100 parts of 325-mesh heavy calcium powder, methyl fiber 2 parts of plain ether, 4 parts of dispersant, 1.5 parts of antifoaming agent, 5 parts of film-forming aids, 1 part of leveling agent, 2 parts of thickening agent, 1 part of mildew and algae inhibitor, 173.5 parts of deionized water;

[0034] The polyamide wax solution is a solution obtained by dissolving polyamide wax and deionized water at a weight ratio of 1:1.

[0035] Among them, the pure acrylic elastic emulsion is a pure acrylic elastic emulsion with low VOC content, particle size less than 0.08um, no APEO, and glass transition temperature -5°C; polyamide wax is a paste with a polyamide mol...

Embodiment 2

[0044] An artistic texture water paint, according to the proportion by weight, the components of the artistic texture water paint include:

[0045] 150 parts of pure acrylic elastic emulsion, 450 parts of 40-80 mesh round sand, 50 parts of 20-40 mesh texture round sand, 30 parts of polyamide wax solution, 50 parts of titanium dioxide, 100 parts of 325-mesh heavy calcium powder, methyl fiber 2 parts of plain ether, 4 parts of dispersant, 1.5 parts of antifoaming agent, 5 parts of film-forming aids, 1 part of leveling agent, 1.5 parts of thickening agent, 1 part of mildew and algae inhibitor, 164 parts of deionized water;

[0046] The polyamide wax solution is a solution obtained by dissolving polyamide wax and deionized water at a weight ratio of 1:1.

[0047] Among them, the pure acrylic elastic emulsion is a pure acrylic elastic emulsion with low VOC content, particle size less than 0.08um, no APEO, and glass transition temperature -5°C; polyamide wax is a paste with a polyamide mol...

Embodiment 3

[0055] An artistic texture water paint, according to the proportion by weight, the components of the artistic texture water paint include:

[0056] 160 parts of pure acrylic elastic emulsion, 450 parts of 40-80 mesh round sand, 50 parts of 20-40 mesh texture round sand, 30 parts polyamide wax solution, 30 parts titanium dioxide, 100 parts 325 mesh heavy calcium powder, methyl fiber 2 parts of plain ether, 6 parts of dispersant, 1.5 parts of antifoaming agent, 5 parts of film forming aids, 1 part of leveling agent, 1.5 parts of thickener, 1 part of anti-mildew and algae inhibitor, and 120 parts of deionized water.

[0057] The polyamide wax solution is a solution obtained by dissolving polyamide wax and deionized water at a weight ratio of 1:1.

[0058] Among them, the pure acrylic elastic emulsion is a pure acrylic elastic emulsion with low VOC content, particle size less than 0.08um, no APEO, and glass transition temperature -5°C; polyamide wax is a paste with a polyamide molecule c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com