Sound-absorbing and noise-reducing putty paste and preparation method thereof

A putty paste and noise reduction technology, applied in the direction of filling slurry, etc., can solve the problems of poor matching of building materials, unsatisfactory effects, not enough safety and environmental protection, etc., to improve storage stability and good adhesion Performance and Utilization Improvement Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

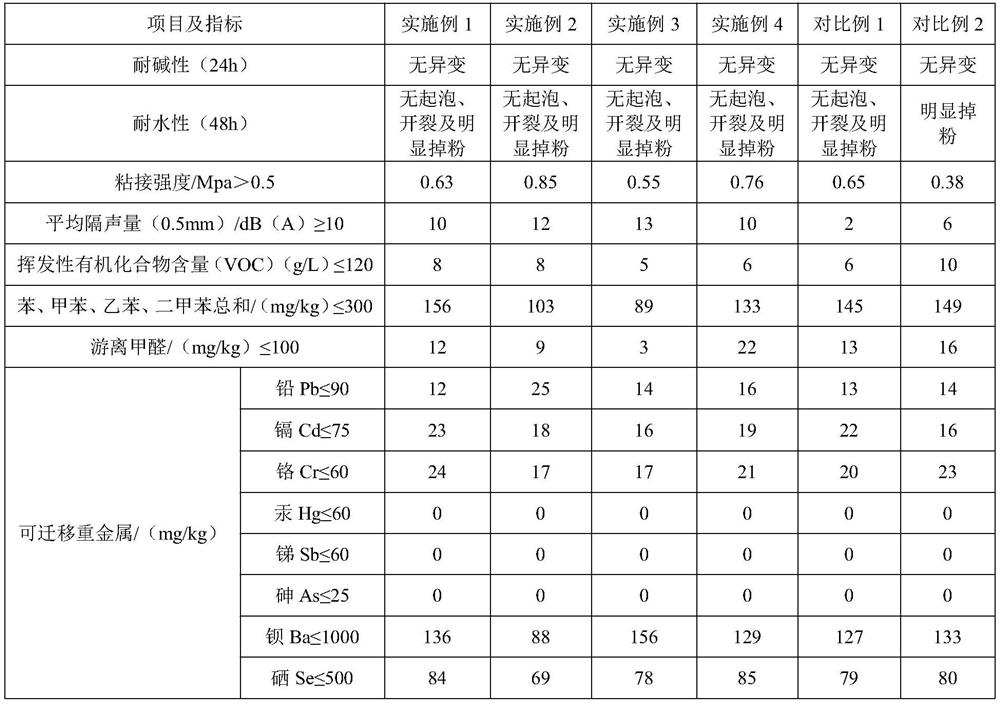

Examples

Embodiment 1

[0031] A sound-absorbing and noise-reducing putty paste and a preparation method thereof, comprising the following steps:

[0032] Add 15.8 parts by weight of water in the reactor, add 10 parts by weight of silica sol under stirring, its solid content is 20%, pH is 9.8, continue to add 0.5 parts by weight of Dow 731A, 0.5 parts by weight of the steady state Agent (Volke B1601), 0.2 parts by weight of BASF 2410, after stirring and mixing into a uniform slurry, add 20 parts by weight of 200 mesh silica gel powder, its pore diameter is 8nm, pore volume is 0.8ml / g, 10 parts by weight of 325 mesh lignocellulosic powder, its aspect ratio greater than 20 content is 70%, 120 mesh quartz powder of 15 parts by weight, 800 mesh calcium carbonate powder of 14 parts by weight, 120 mesh floating beads of 3 parts by weight, stir under 1000rpm After 20 minutes to a uniform slurry, add 0.5 parts by weight of Taoxi OFS-6020, continue to stir for 60 minutes, add 7 parts by weight of styrene-acry...

Embodiment 2

[0034] A sound-absorbing and noise-reducing putty paste and a preparation method thereof, comprising the following steps:

[0035] Add 10.2 parts by weight of water in the reaction kettle, add 15 parts by weight of silica sol under stirring, its solid content is 30%, pH is 10.3, continue to add 0.8 parts by weight of Gaotai 123k, 1.0 parts by weight of the steady state Agent (Volke B1601), 0.2 parts by weight of BASF NXZ, after stirring and mixing into a uniform slurry, add 15 parts by weight of 400 mesh silica gel powder, its pore diameter is 8nm, pore volume is 0.85ml / g, 8 parts by weight of 400 mesh lignocellulosic powder, its length-to-diameter ratio greater than 20 is 86%, 15 parts by weight of 800 mesh wollastonite powder, 15 parts by weight of 200 mesh calcium carbonate powder, after stirring at 800rpm for 22min to a uniform slurry, Add 0.5 parts by weight of Pinning KH550, continue stirring for 90 minutes, respectively add 4 parts by weight of styrene-acrylic emulsion,...

Embodiment 3

[0037]A sound-absorbing and noise-reducing putty paste and a preparation method thereof, comprising the following steps:

[0038] Add 18.6 parts by weight of water in the reactor, add 8 parts by weight of silica sol under stirring, its solid content is 25%, pH is 10, continue to add 0.6 parts by weight of Dow CA-2500, 0.5 parts by weight of Stabilizer (Volke B1601), 0.4 parts by weight of Tao Xi DOWSIL8590, after stirring and mixing into a uniform slurry, add 18 parts by weight of 400 mesh silica gel powder, its pore diameter is 10nm, and the pore volume is 1.0ml / g, 12 The 400 mesh lignocellulosic powder of weight part, its length-to-diameter ratio is greater than 20 content is 86%, the 800 mesh wollastonite powder of 10 weight parts, the 200 mesh calcium carbonate powder of 10 weight parts, stir 25min under 700rpm to uniform slurry After solidification, add 0.5 parts by weight of Liancarb A-1100, continue to stir for 90 minutes, add 14 parts by weight of pure acrylic emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com