Method for forming metal plates and flexible production line thereof

A flexible production line, metal sheet technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems that are not conducive to enterprise development, increase production cycle, consume time, etc., to shorten production cycle, increase competitiveness, and structural layout reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

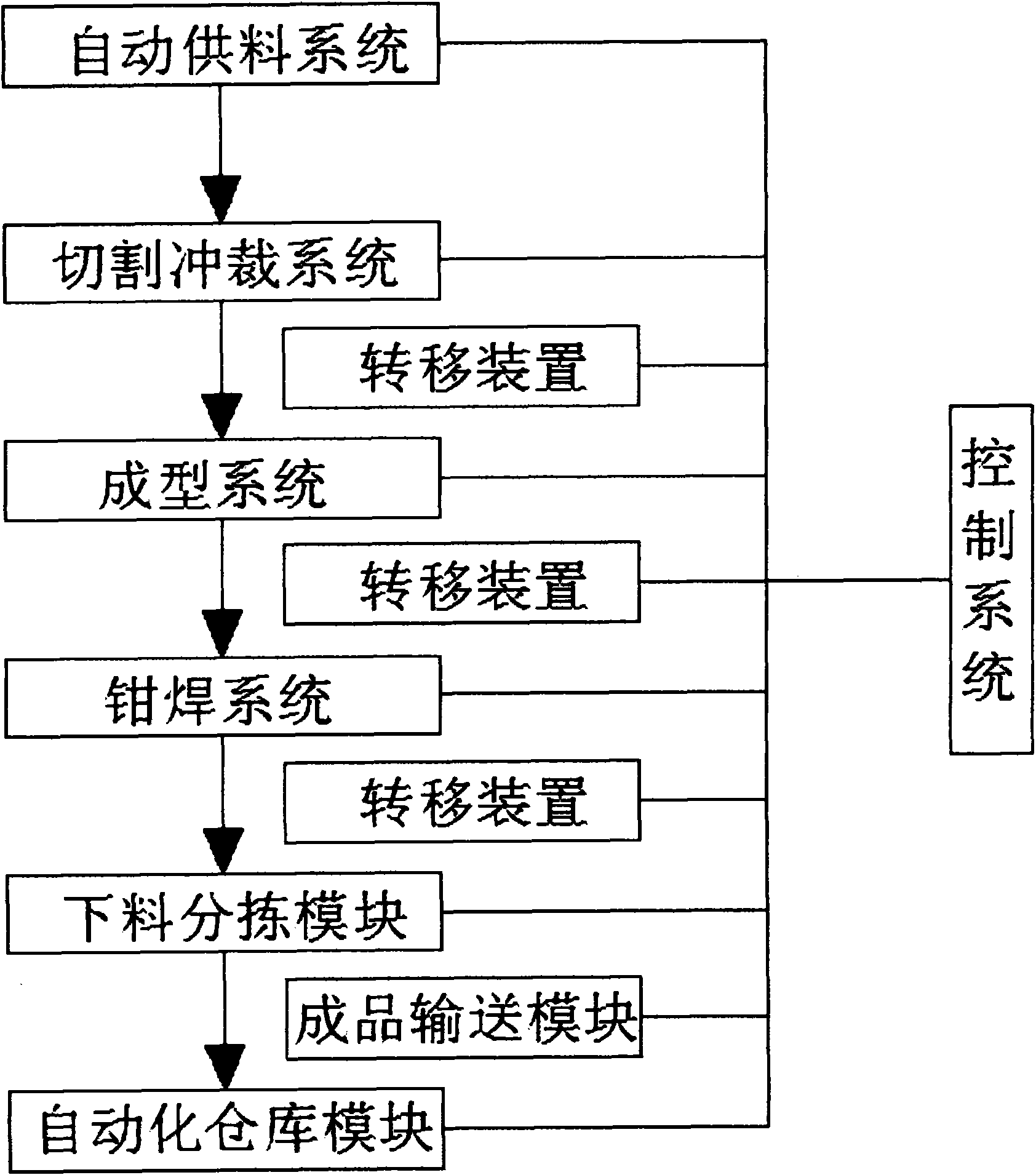

[0049] Example: see Figure 1 to Figure 5 , This embodiment provides a metal sheet forming method, which includes the following steps:

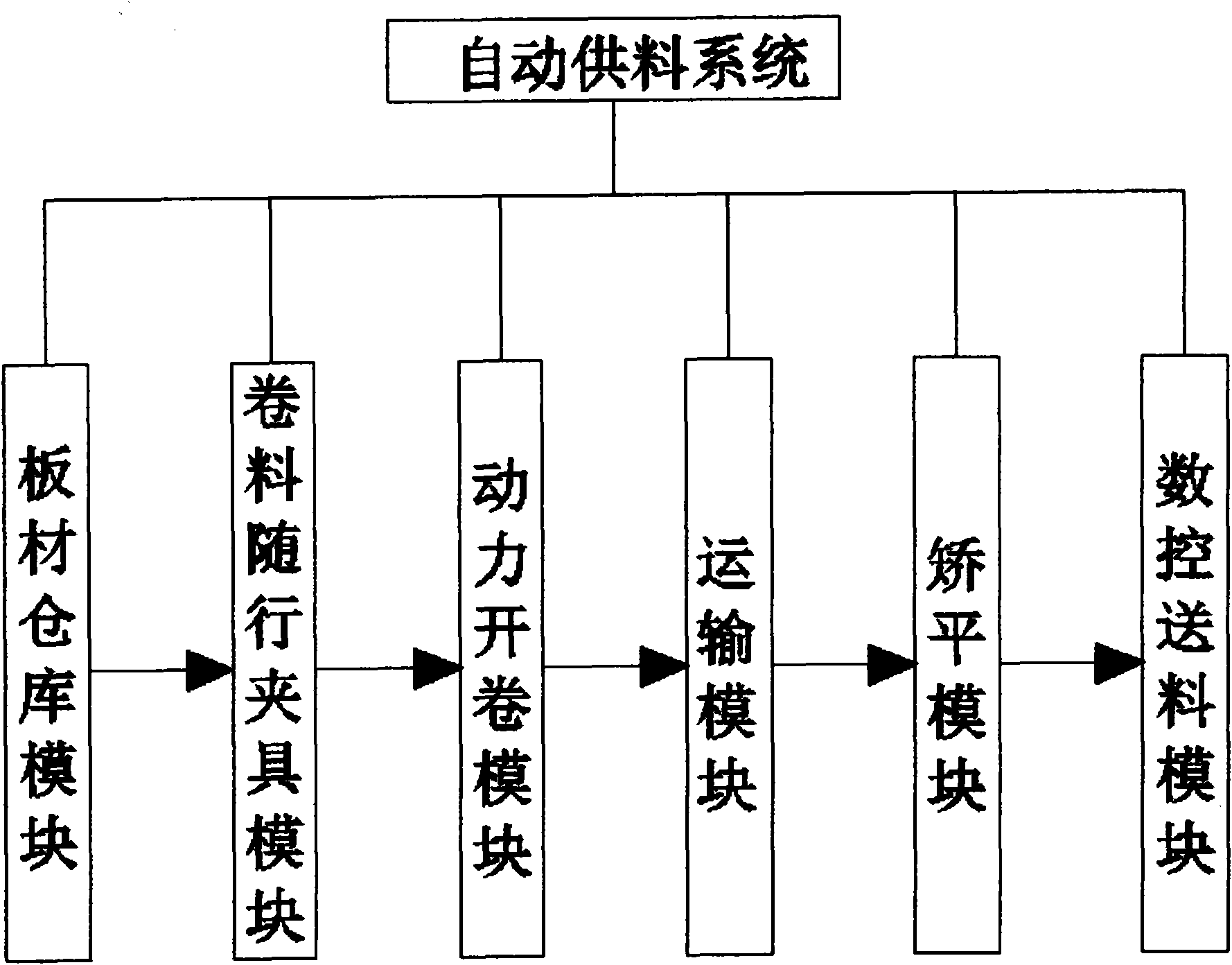

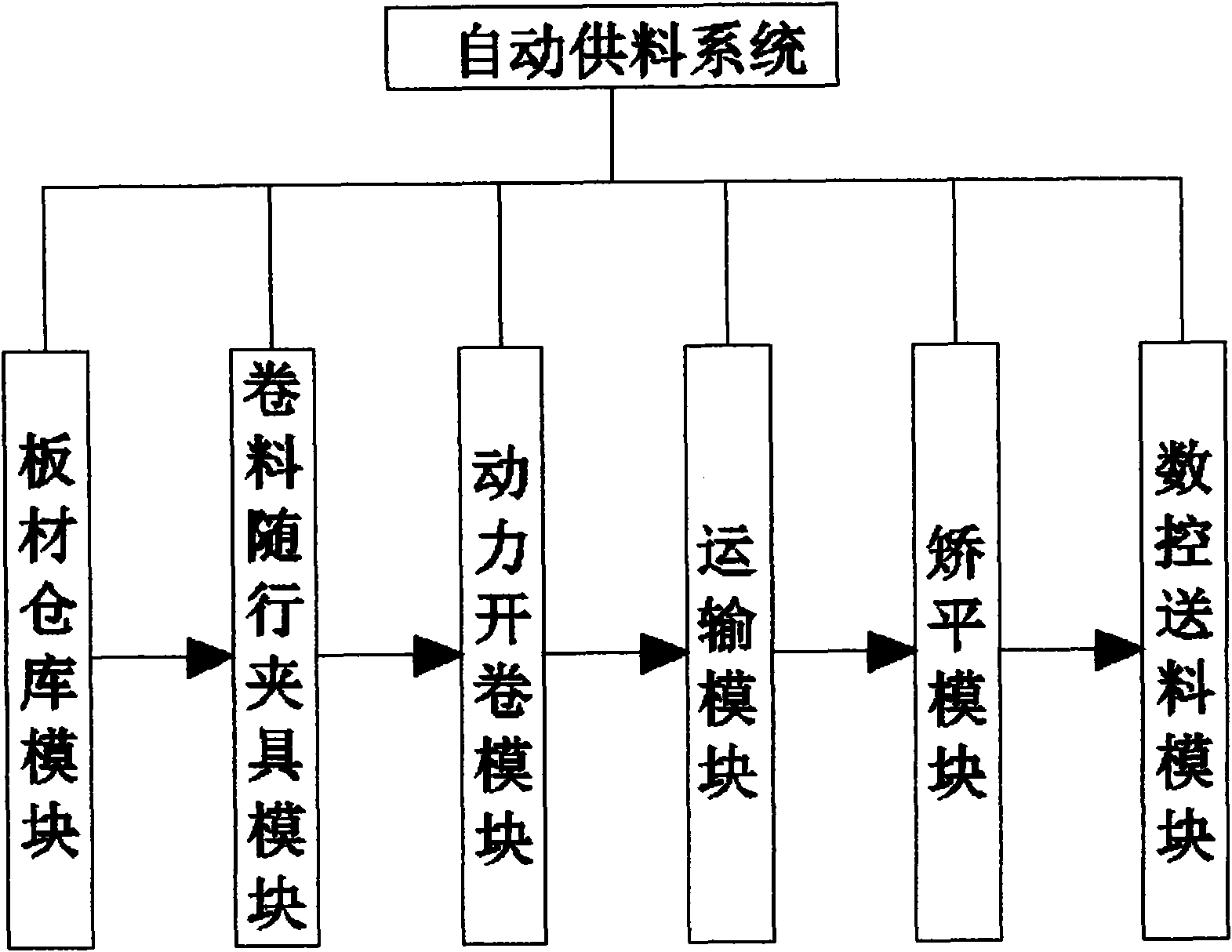

[0050] (1) An automatic feeding system is set up to automatically feed the metal sheet to be formed to realize the feeding action; the step (1) specifically includes the following steps:

[0051] (1.1) Set up a plate warehouse module to manage and store metal plates to be formed;

[0052] (1.2) Set up a roll material accommodating fixture module to clamp the metal sheet to be formed;

[0053] (1.3) A power uncoiling module is provided to drive the coil material accompanying clamp module to realize the forward transportation of the metal sheet to be formed along the direction of the production line;

[0054] (1.4) Set up a transport module to transfer the coil accompaniment module to deliver the metal sheet to be formed to the power uncoiling module or to transport the coil accommodating fixture module that has been transported to the predetermined loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com