Automatic natural gas continuous-sampling control system

A sampling system, natural gas technology, applied in the field of natural gas automatic control continuous sampling system, can solve the problems of inconsistency between sampling components and actual medium, low degree of automation, gas condensation, etc., to reduce workload, ensure personal safety, and simplify operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

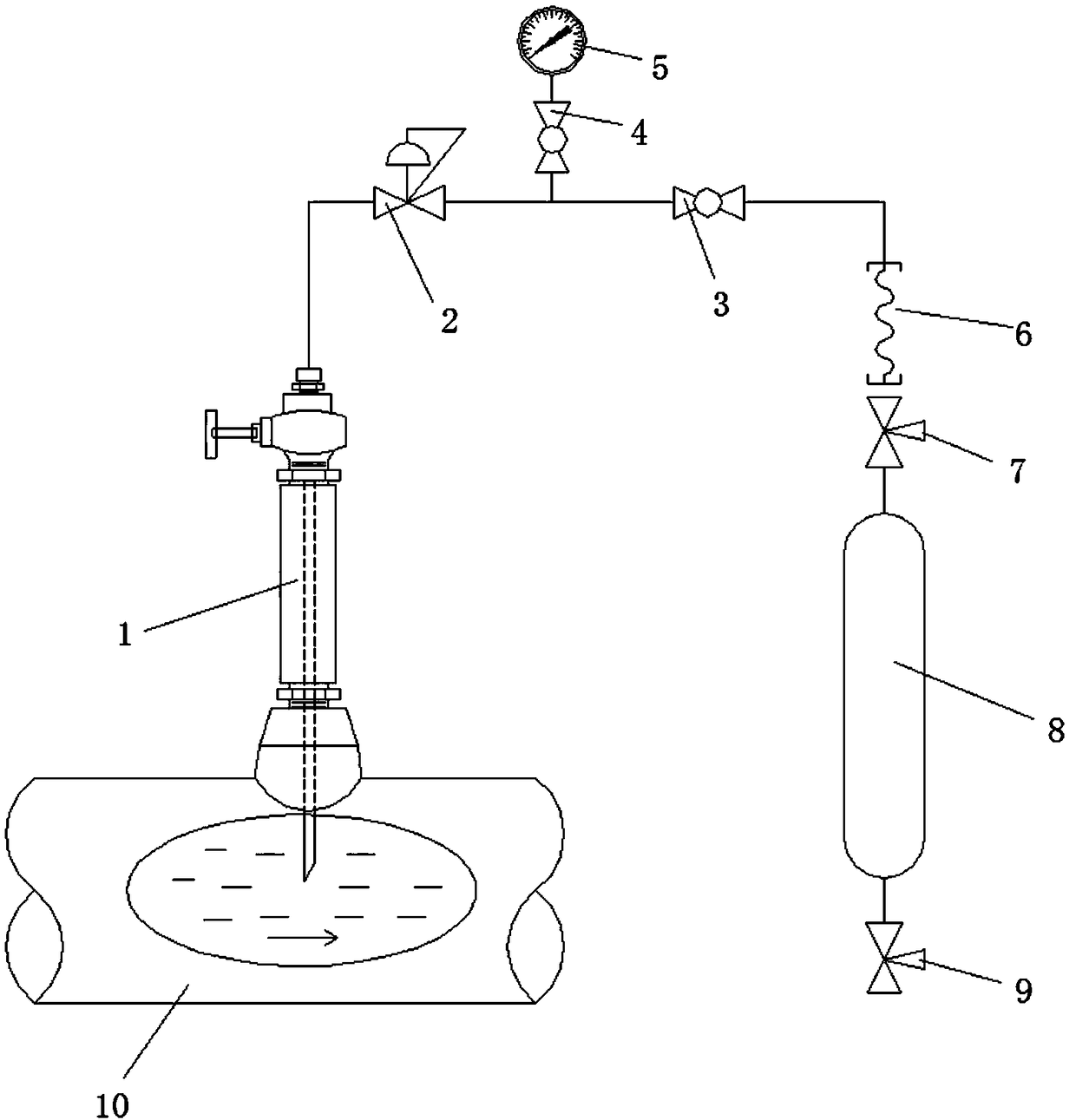

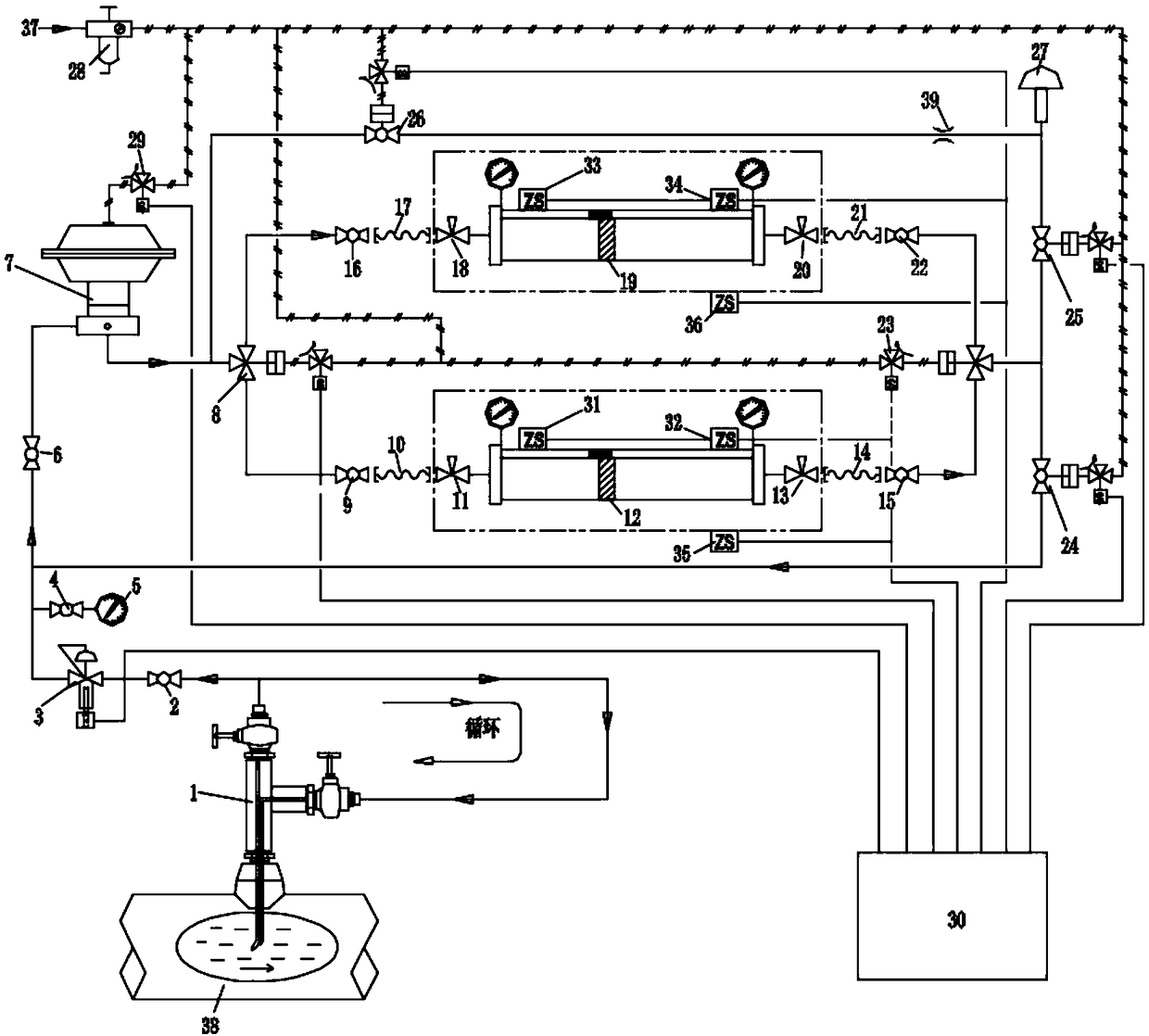

[0035] Natural gas automatic control continuous sampling system, including sampling probe 1 and pressure reducing valve 3 connected with natural gas pipeline 38, the inlet of pressure reducing valve 3 is connected with the outlet of sampling probe 1, and the outlet of pressure reducing valve 3 is divided into Two paths, one of which is connected to the pneumatic diaphragm sampling pump 7, and the other is connected to the outlet ports of the first constant pressure sampling steel cylinder 12 and the second constant pressure sampling steel cylinder 19 respectively through pipelines. The pneumatic diaphragm sampling pump 7 is pneumatically operated by the solenoid valve 29. Control, the instrument air source 37 pneumatically controlled by the solenoid valve 29 comes from the instrument air, and the solenoid valve 29 is controlled by the sampling control panel 30. 29 acts on the diaphragm of the pneumatic diaphragm sampling pump 7, and the diaphragm pump acts once to send a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com