Multi-station speed-governing numerically-controlled drilling machine

A CNC drilling machine and multi-station technology, which is applied to the parts of boring machine/drilling machine, manufacturing tools, boring/drilling, etc., can solve the problems that the accuracy is difficult to meet the requirements, and the processing efficiency cannot be improved well, so as to achieve the overall Reasonable and compact structure, control positioning error, save floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

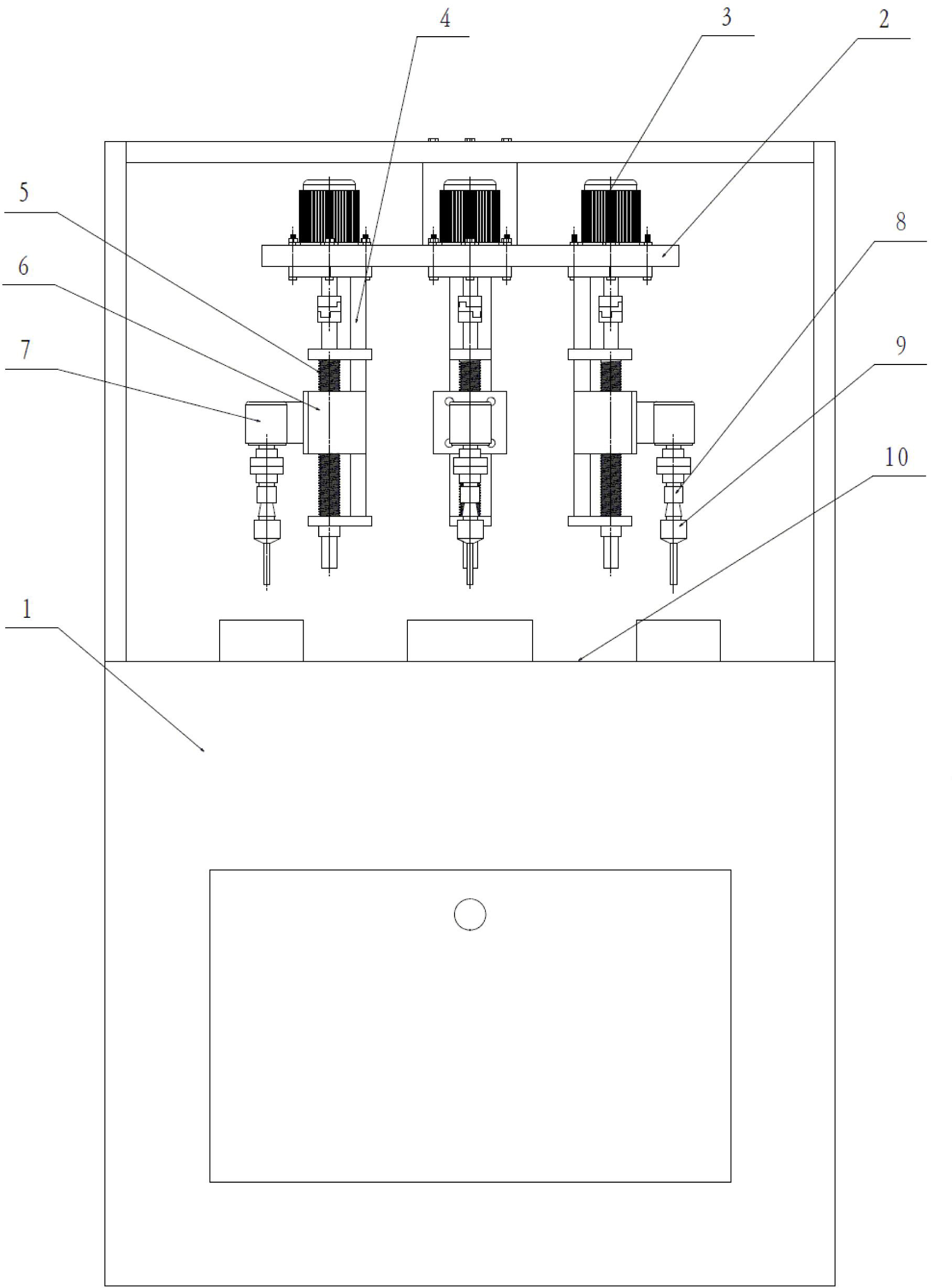

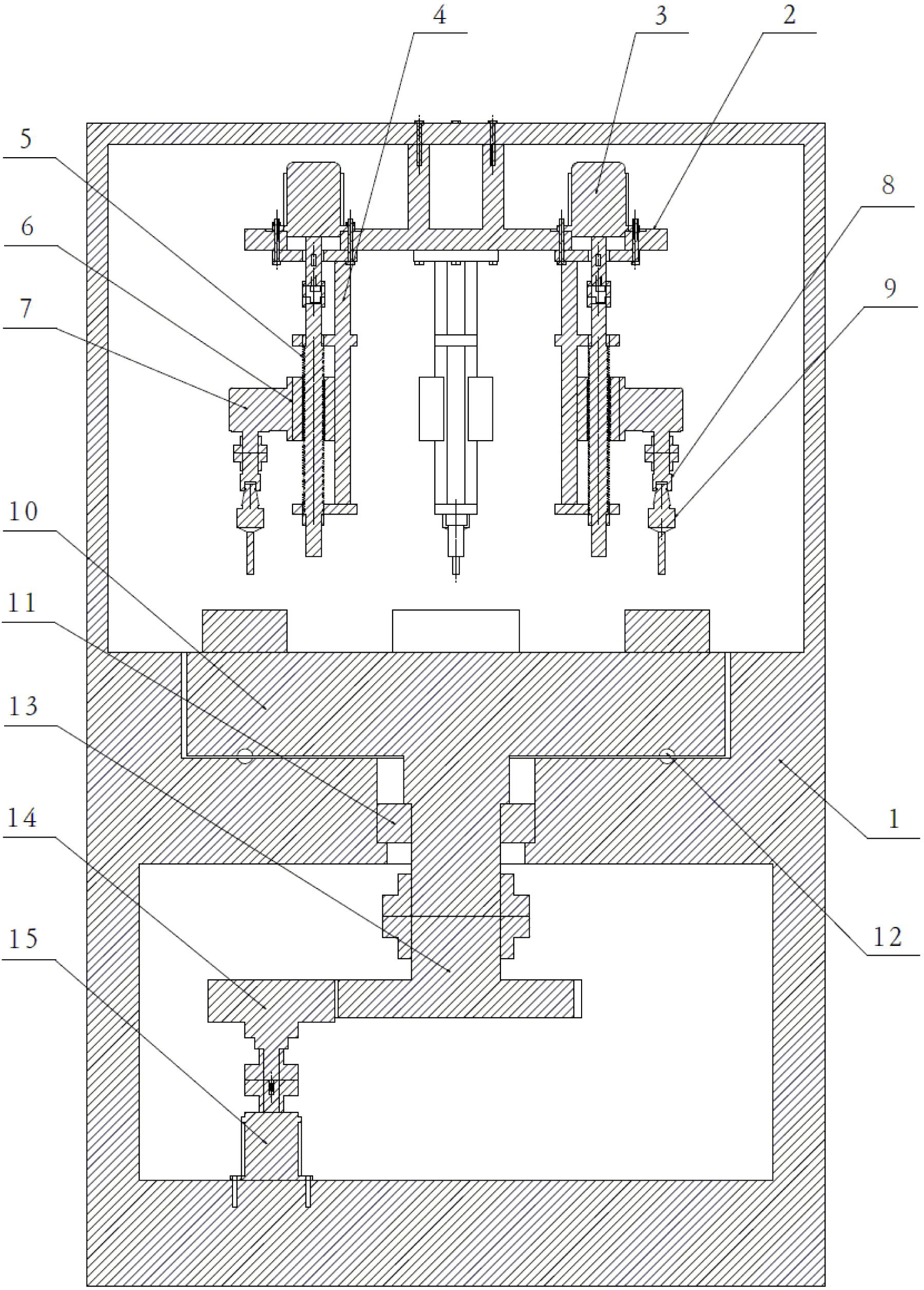

[0035] Such as figure 1 , figure 2 , image 3 As shown, the multi-station speed-adjustable CNC drilling machine of the present invention includes a vertically placed machine bed 1, on which a rotary table device and a cutter device are arranged; the cutter device is arranged above the rotary table device;

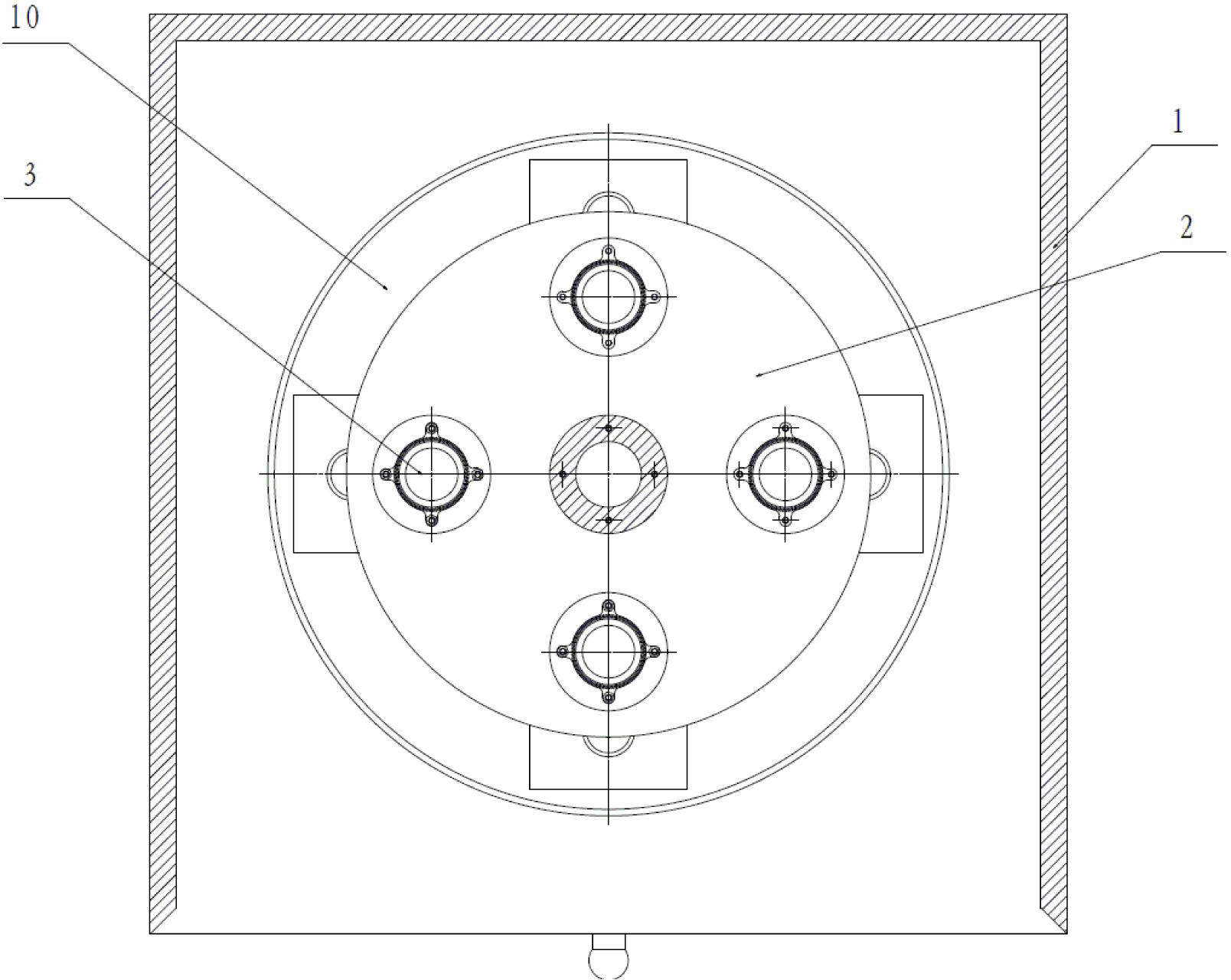

[0036] Such as Figure 4 As shown, the rotary table device includes a rotary motion control servo motor 15, a No. 1 gear 14, a No. 2 gear 13, a self-aligning roller bearing 11, and a rotary table 10. The output shaft of the rotary motion control servo motor 15 passes through an elastic cylindrical pin The coupling is connected with the No. 1 gear 14, which drives the No. 1 gear 14 to rotate, and the No. 1 gear 14 meshes with the No. 2 gear 13. The No. 2 gear 13 is connected with the rotary table 10 through the elastic cylindrical pin coupling, and the parts are clamped in the On the rotary table 10, the rotary of parts is realized. The rotary table 10 is movably connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com