T-shaped stirring drilling machine

A technology for mixing drilling rigs and electric motors, which is used in construction, sheet pile walls, infrastructure engineering and other directions to achieve strong bending resistance and good anti-seepage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

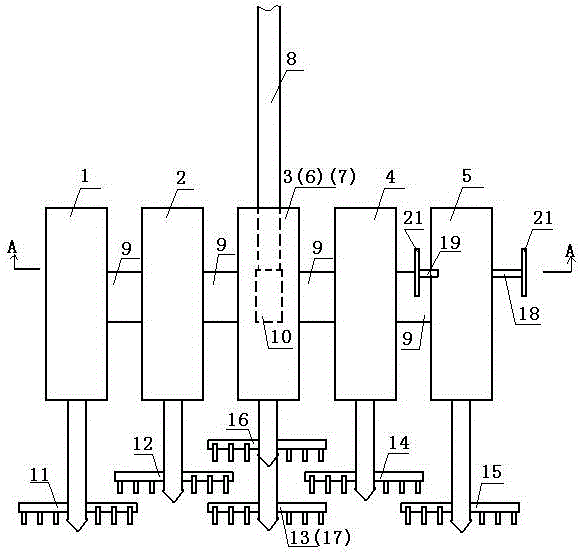

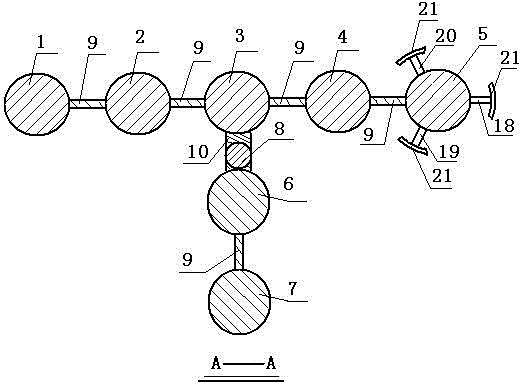

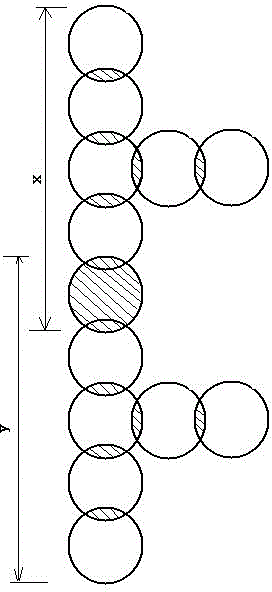

[0014] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment electric motor A1, electric motor B2, electric motor C3, electric motor D4, electric motor E5, electric motor F6, electric motor G7 form a T-shaped frame, wherein electric motor A and electric motor B, electric motor B It is connected and fixed with motor C, motor C and motor D, motor D and motor E, motor F and motor G respectively through a connecting rod A9, motor C and motor F are connected and fixed through a connecting rod B10, and the lower end of the drilling rod 8 is fixed on At the position of the center of gravity of the T-shaped frame, the lower end of the drilling rod 8 is fixed on the connecting rod B; the lower end of the motor A is provided with the stirring rotary head A11, the lower end of the motor B is provided with the stirring rotary head B12, and the lower end of the motor C is provided with the stirring rotary head C13. The lower end of D is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com