Correcting method for high speed railway ballastless track subgrade in soft soil area

A technology for high-speed railways and ballastless tracks, applied in roads, tracks, buildings, etc., can solve problems such as great constraints on the selection of deviation correction schemes, high risks, and short skylight time, and achieve easy control of construction quality, flexible and controllable operations, and The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

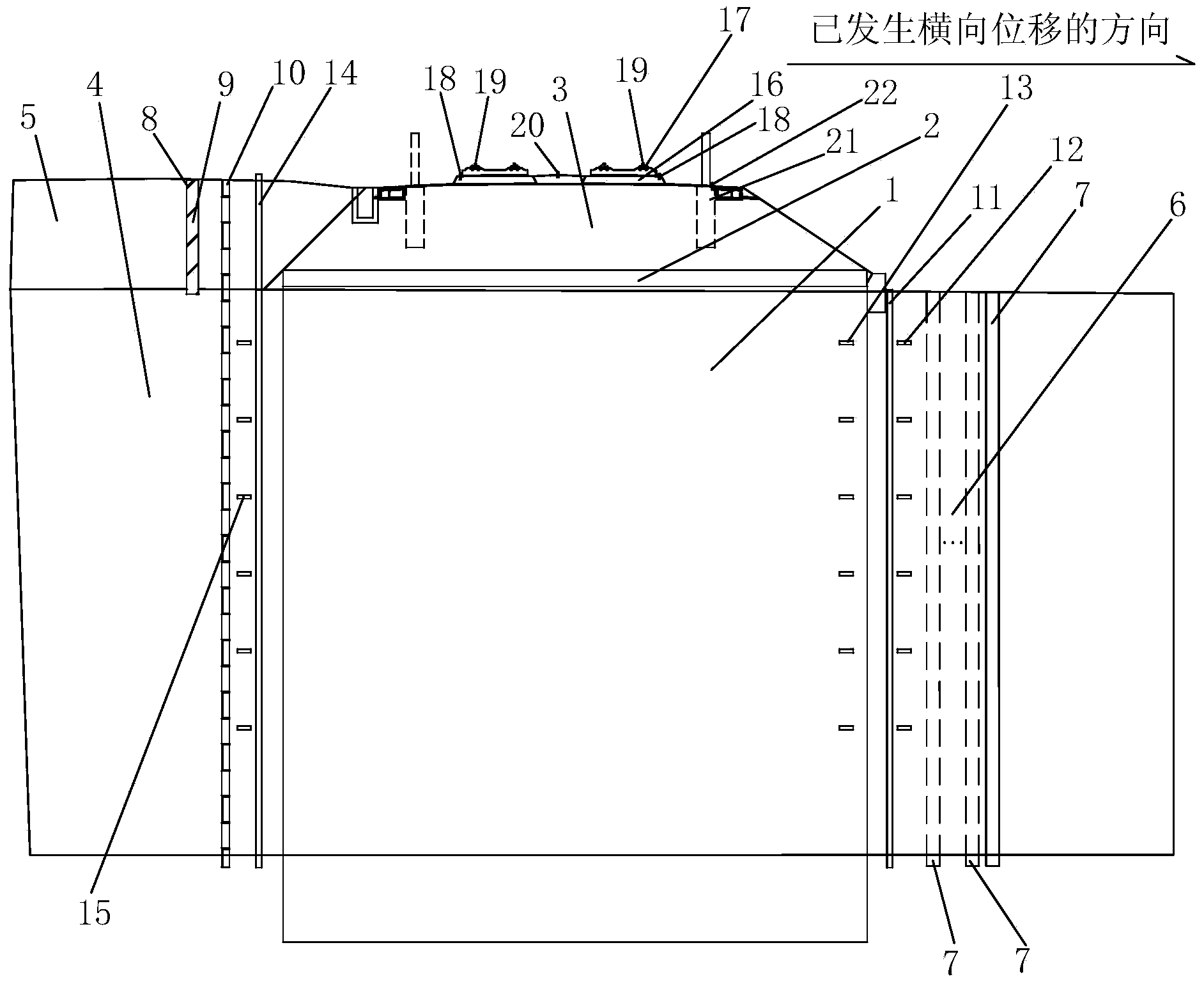

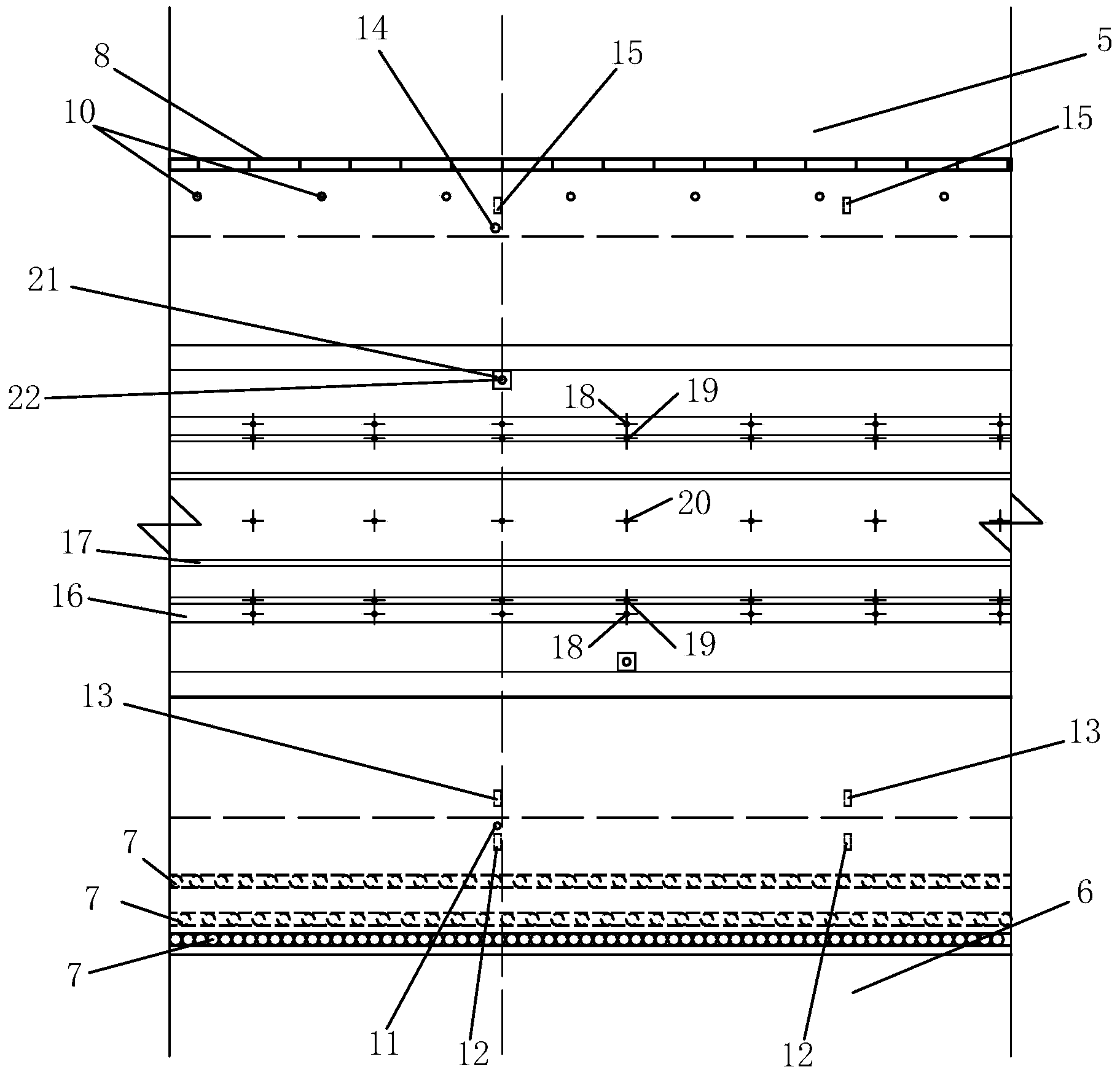

[0027] Such as figure 1 and figure 2 The deviation correction method for the ballastless track subgrade of the high-speed railway in the soft soil area is shown, and the applicable environmental structure of the method includes the pile foundation reinforcement area 1, the foundation reinforcement cushion layer 2 set on the top of the pile foundation reinforcement area 1, and the The high-speed railway embankment 3 on the top of the foundation reinforcement cushion 2, the first weak formation area 4 located on one side of the pile foundation reinforcement area 1, the asymmetric load area 5 located on the top of the first weak formation area 4, and the other side of the pile foundation reinforcement area 1 The second weak formation area 6 on one side, the asymmetric load area 5 is located on one side of the foundation reinforcement cushion 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com