Steel pillar supporting type integral self-lifting steel platform scaffold template system and constructing method thereof

A technology of integral steel and steel platform, applied in the direction of formwork/formwork/work frame, scaffolding supported by house structure, housing structure support, etc., can solve the problem of poor integrity of climbing formwork, poor working environment stability of climbing formwork, and unattainable concrete quality. High quality requirements and other issues, to achieve the effect of short construction period and easy control of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

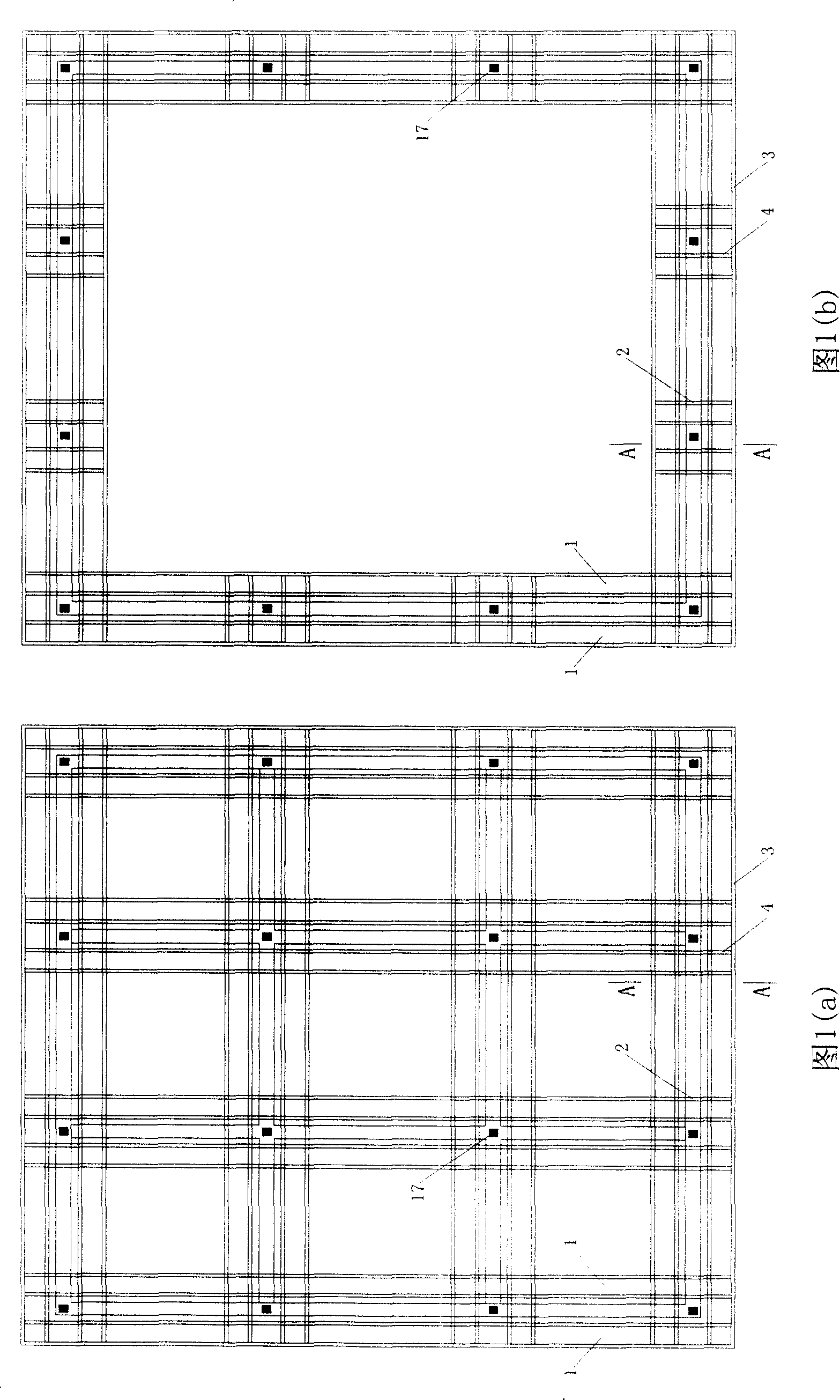

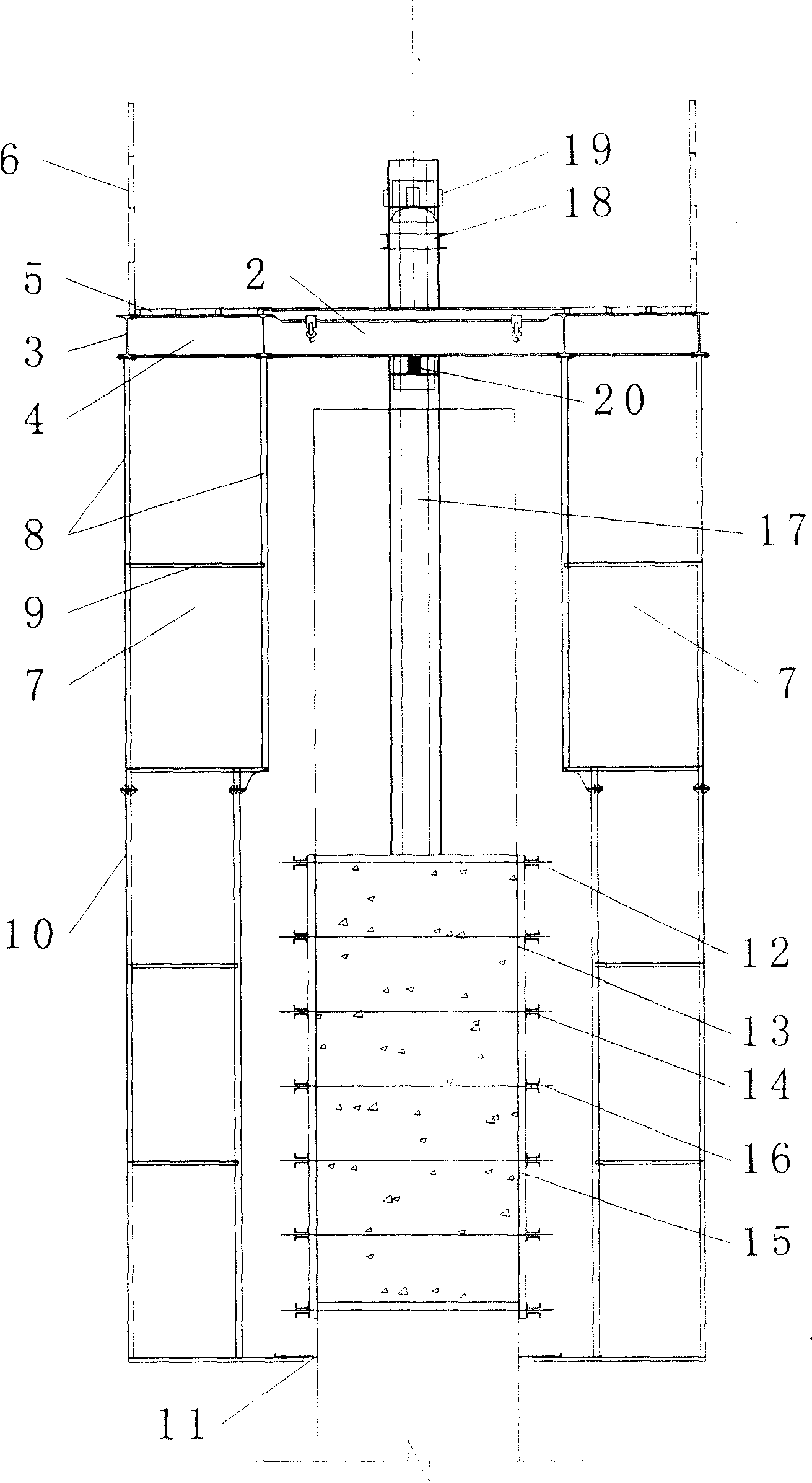

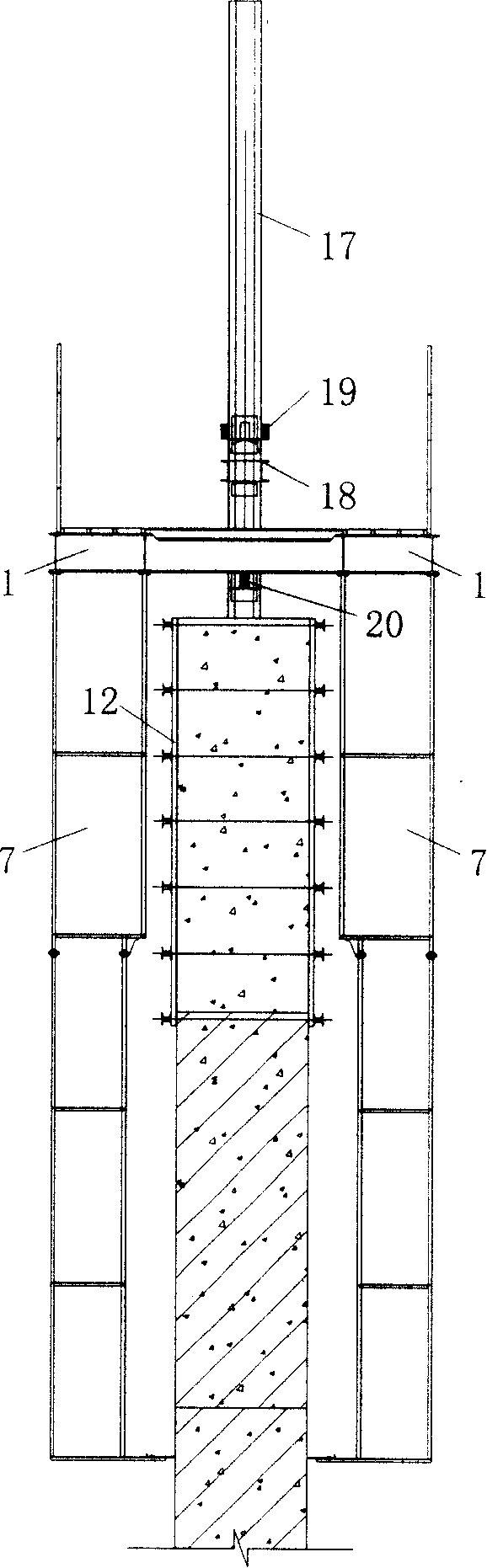

[0022] The characteristics and advantages of the present invention are described in detail through specific embodiments of the present invention in conjunction with the accompanying drawings. See Figure 1, figure 2 , the scaffold formwork system device of the steel column supported integral self-elevating steel platform in this embodiment includes:

[0023] An integral steel platform composed of sub-platform 1 and connecting beam 2 arranged around the inner and outer sides of the concrete structure. The sub-platform is composed of main beam 3 and secondary beam 4. Truss, I-beam, H-beam and other forms. The peripheral edges of the integral steel platform are all closed with block nets 6 to prevent people and things from falling from the integral steel platform to ensure safety. Blocking net 6 is made up of channel steel column, angle steel frame and steel wire mesh, and the height of blocking net generally is 2 meters. Sub-platform 1 is paved with a steel cover plate, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com