Quick-mounting type concrete stair and mounting method thereof

An installation method and concrete technology, which can be applied to stairs, buildings, building structures, etc., can solve the problems of complex construction process, cumbersome installation process, long construction time, etc., to overcome the complex construction process, good integrity, and reduce construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

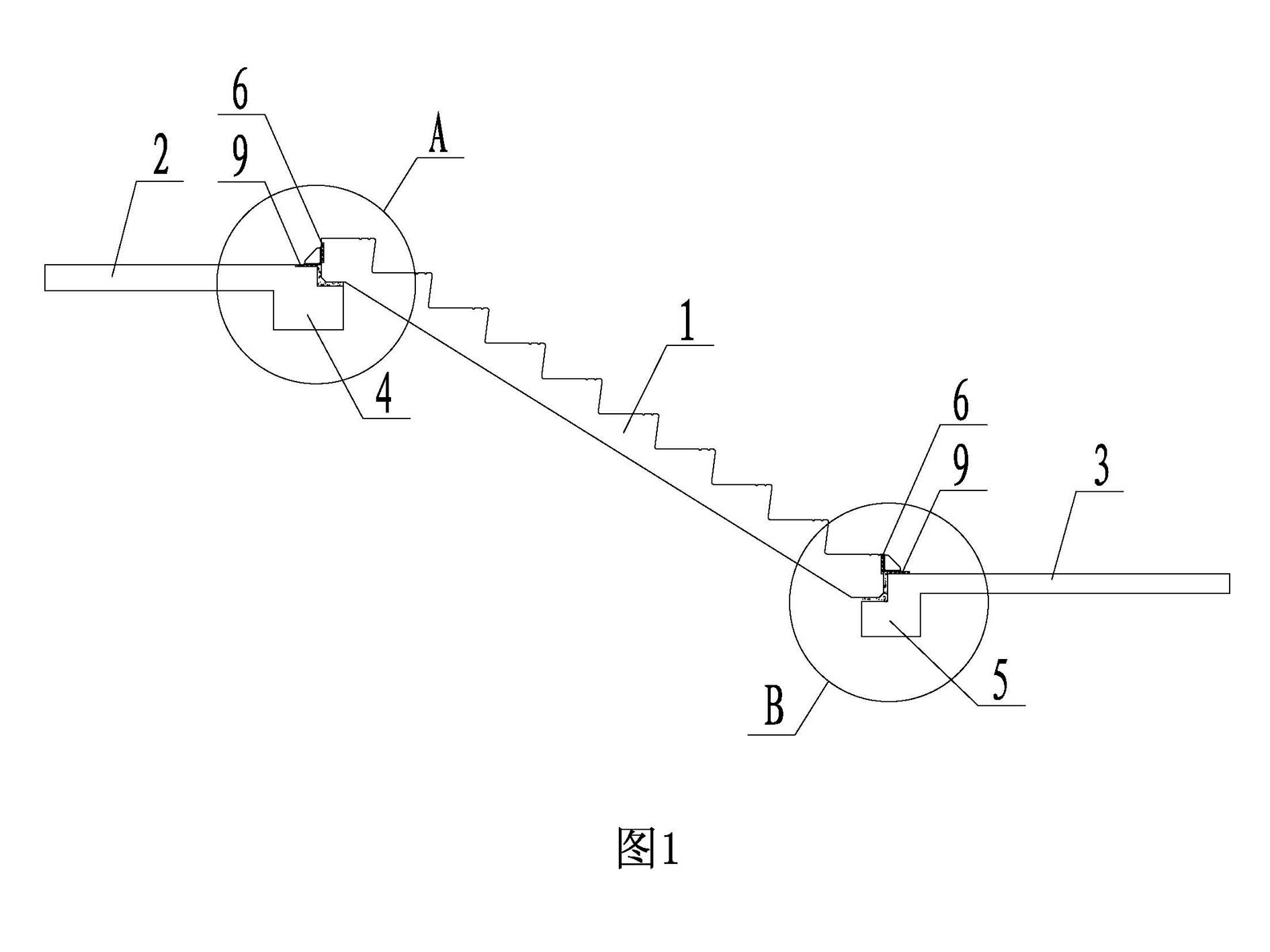

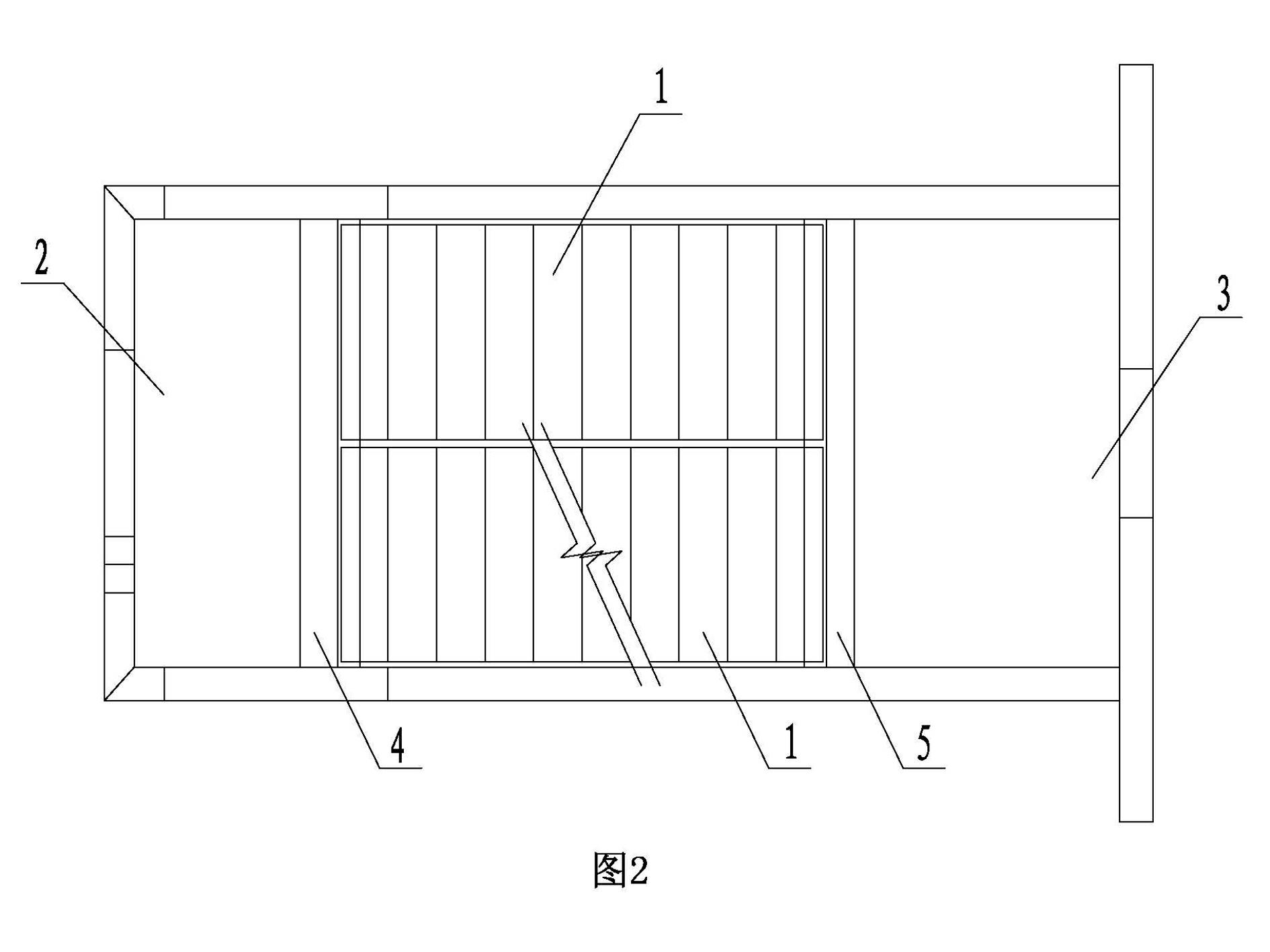

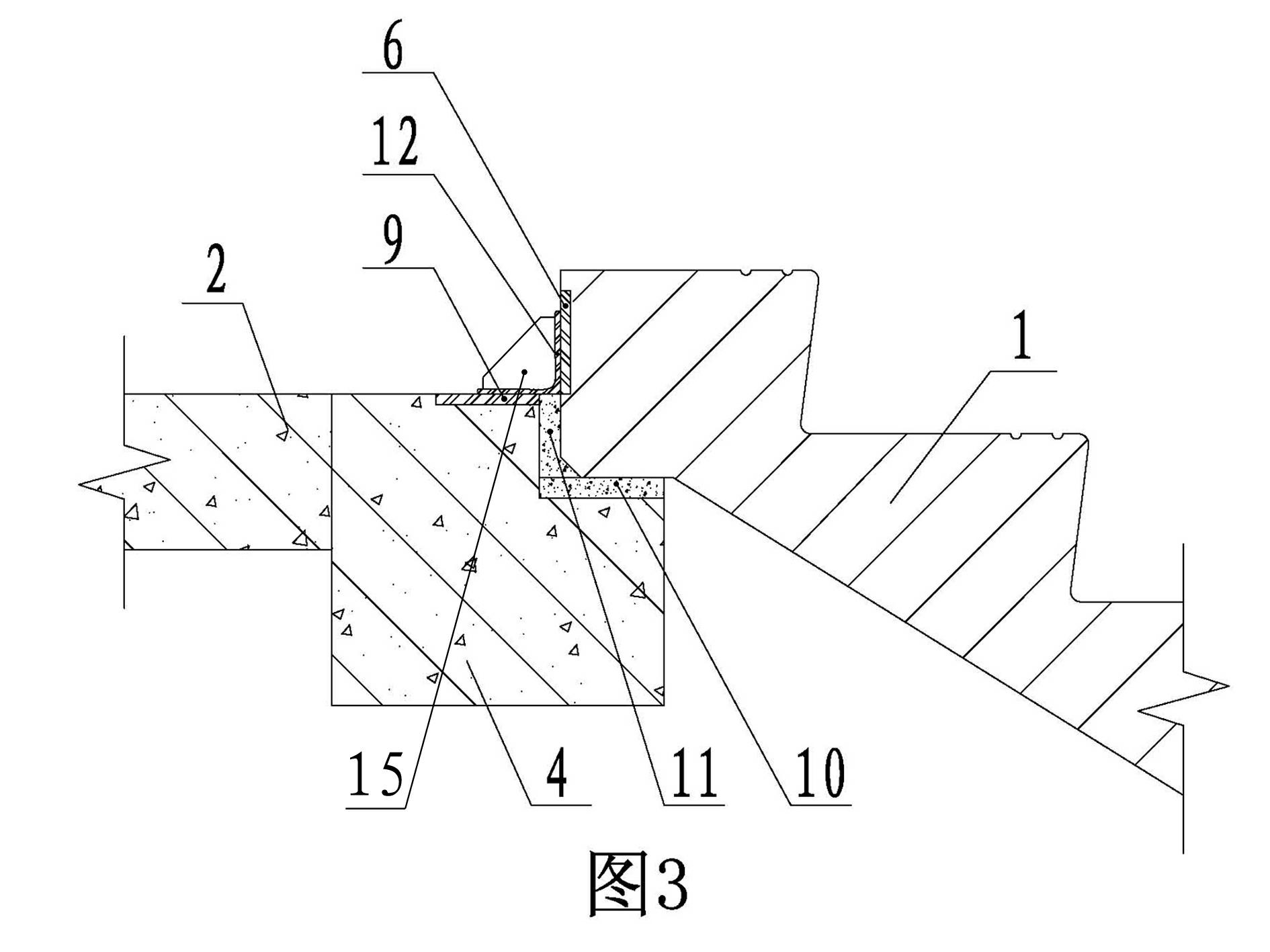

[0039] Embodiment one sees Figure 1-4 , Figure 7-8 As shown, a quick-installed concrete staircase comprises a prefabricated stair section 1, a cast-in-place upper stair platform 2, a cast-in-place lower stair platform 3, a cast-in-place upper stair beam 4 and a cast-in-place lower stair beam 5, the prefabricated stair section 1 and the vertical surface of the connection end of the cast-in-place upper stair platform 2 and the cast-in-place lower stair platform 3 are respectively embedded with at least two stair section embedded parts 6, and the stair section embedded parts 6 are embedded in the prefabricated stair section 1 On the facades at both ends, the prefabricated ladder section 1 is pre-embedded with hoisting parts 8,

[0040] The cast-in-place upper staircase platform 2 is integrated with the cast-in-place upper staircase beam 4, the cast-in-place lower staircase platform 3 is integrated with the cast-in-place lower staircase beam 5, and the cast-in-place upper stair...

Embodiment 2

[0044] Embodiment two see Figure 9-10 As shown, different from Embodiment 1, Embodiment 2 is that the prefabricated ladder section is connected to the ground of the first floor. In order to strengthen the embedded part 9 of the ladder beam, a piece of the same prefabricated ladder beam can be welded with the connecting rib 14 during processing. Embedded parts9. The two ladder beam embedded parts 9 are steel plates opposite to each other at intervals, and the two steel plates are connected by connecting ribs 14 perforated plug welding. The two ladder beam embedded parts 9 are parallel, and the connecting ribs 14 and the two ladder beam embedded parts 9 are vertical. After the prefabricated stair section is installed, the first floor slab 13 is poured to make it a whole, and the leveling layer 10 is poured between the prefabricated stair section 1 and the ground floor slab to fix it. The leveling layer 10 can use C25 fine stone concrete.

[0045] The installation method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com