Outer partition wall built by adopting light concrete partition wall boards and construction method thereof

A technology of lightweight concrete and construction methods, applied to building structures, processing of building materials, walls, etc., to achieve the effects of increasing safety assurance, shortening the construction period, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

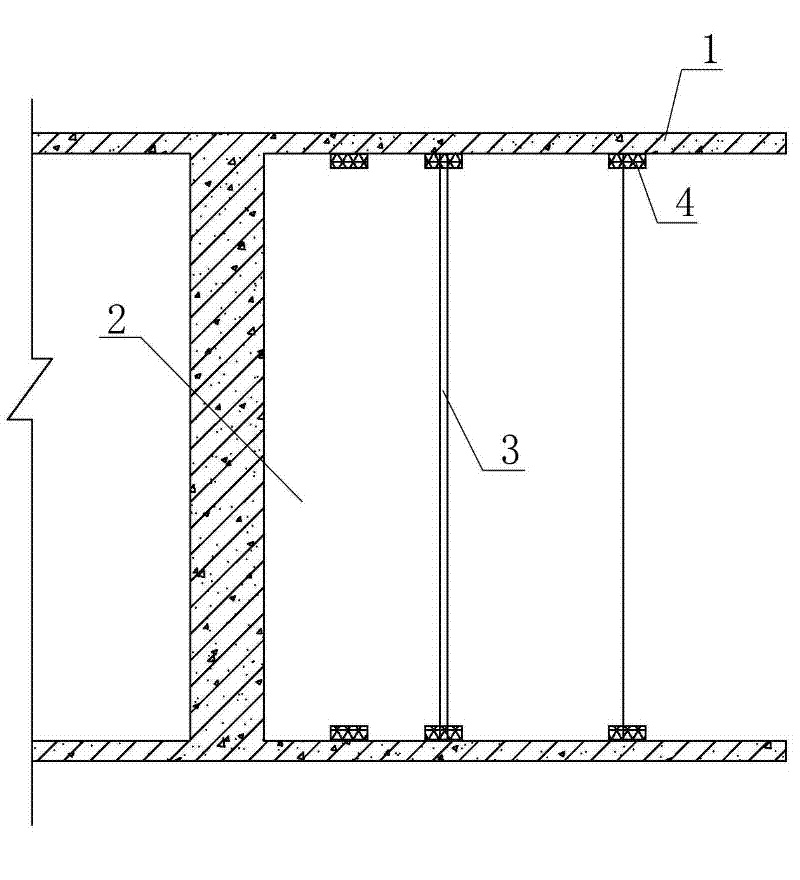

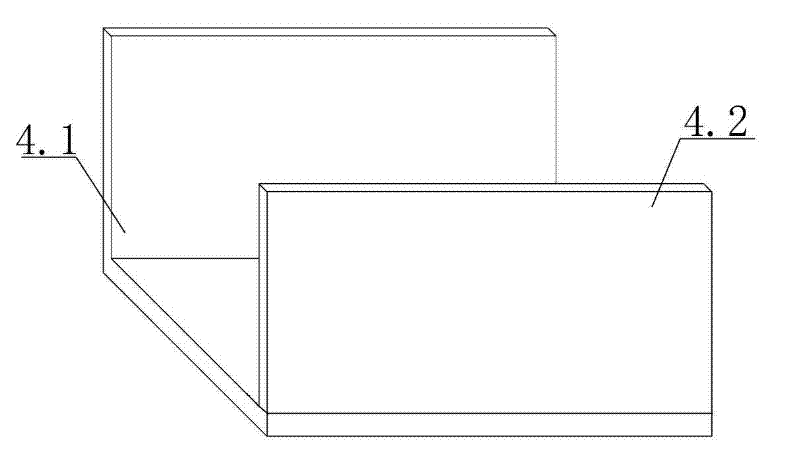

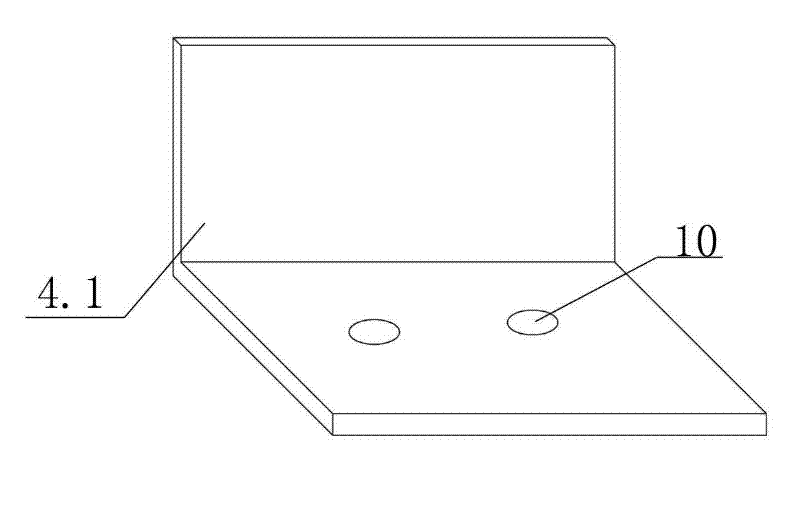

[0033] Examples see Figure 1 ~ Figure 3 As shown, an external partition wall made of lightweight concrete partition boards is spliced by several side-by-side lightweight aggregate concrete partition boards 2, and is arranged between two adjacent side boards 1 of the main structure. The top and bottom ends of the joint 3 of the light aggregate concrete partition wall panel 2 are covered with groove-shaped rear embedded parts, and the groove-shaped rear embedded parts 4 are welded by L-shaped steel plates 4.1 and straight steel plates 4.2. The horizontal side of the L-shaped steel plate 4.1 and the side plate 1 are fixed by expansion bolts 6, and the vertical side is flush with the outer edge of the side plate. The vertical distance between the layer side panels 1 is short, the lightweight aggregate concrete partition wall panel 2 is tightly pressed against the top groove-shaped post-embedded part, and the gap between the bottom groove-shaped post-embedded part is filled with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com