Novel energy-consumption shock-absorbing filling wall board used for frame structure

A frame structure and filling wall technology, applied in the direction of walls, anti-seismic, building components, etc., can solve the problems of reduced anti-seismic capacity of the frame structure, misalignment of the center of rigidity and center of gravity of the structure, changing the dynamic characteristics of the frame structure, etc., to avoid adverse effects, The effect of improving the earthquake resistance and increasing the safety margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention provides a novel energy-dissipating and shock-absorbing filling wallboard for frame structures, and the present invention will be further described below through the description of drawings and specific implementation methods.

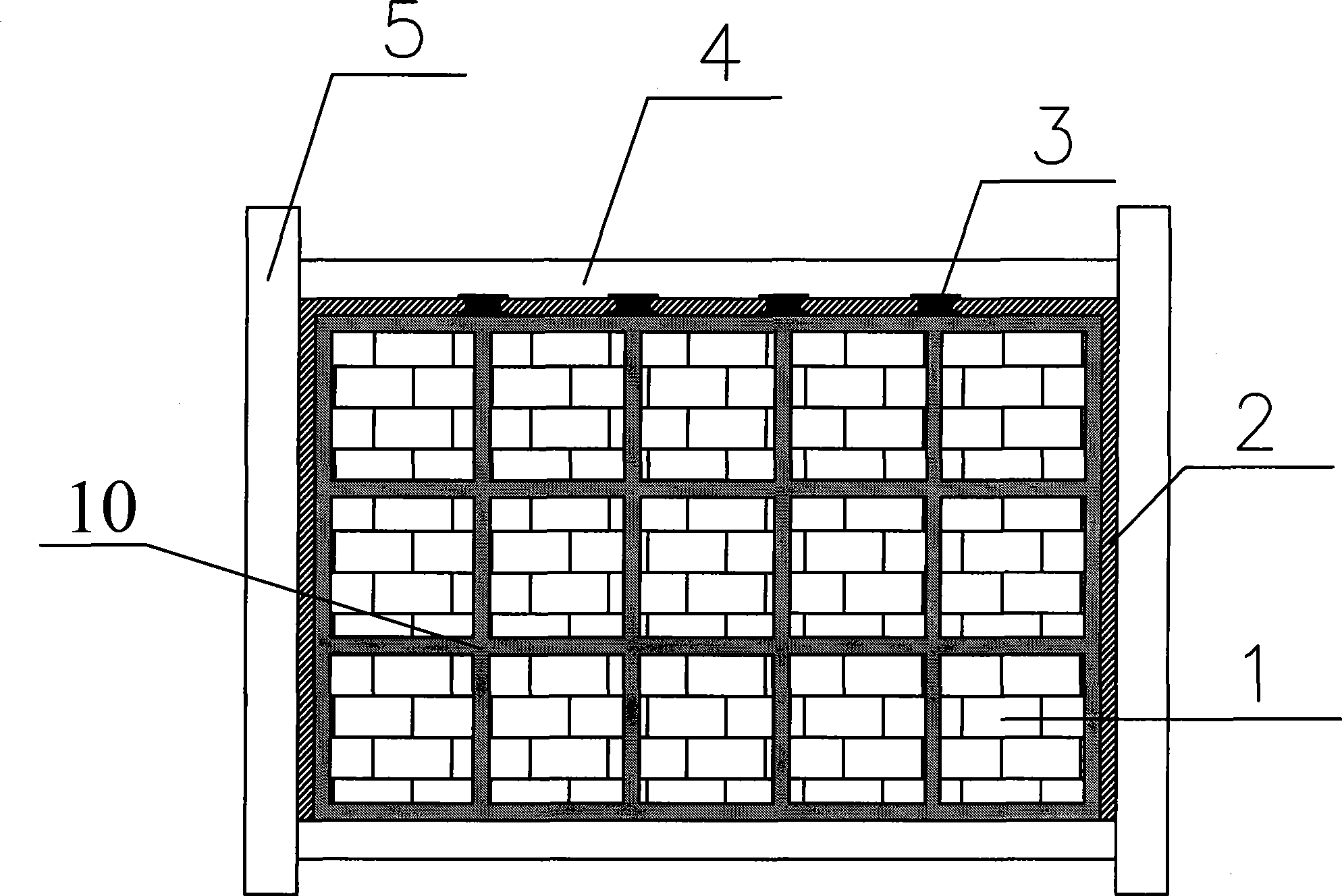

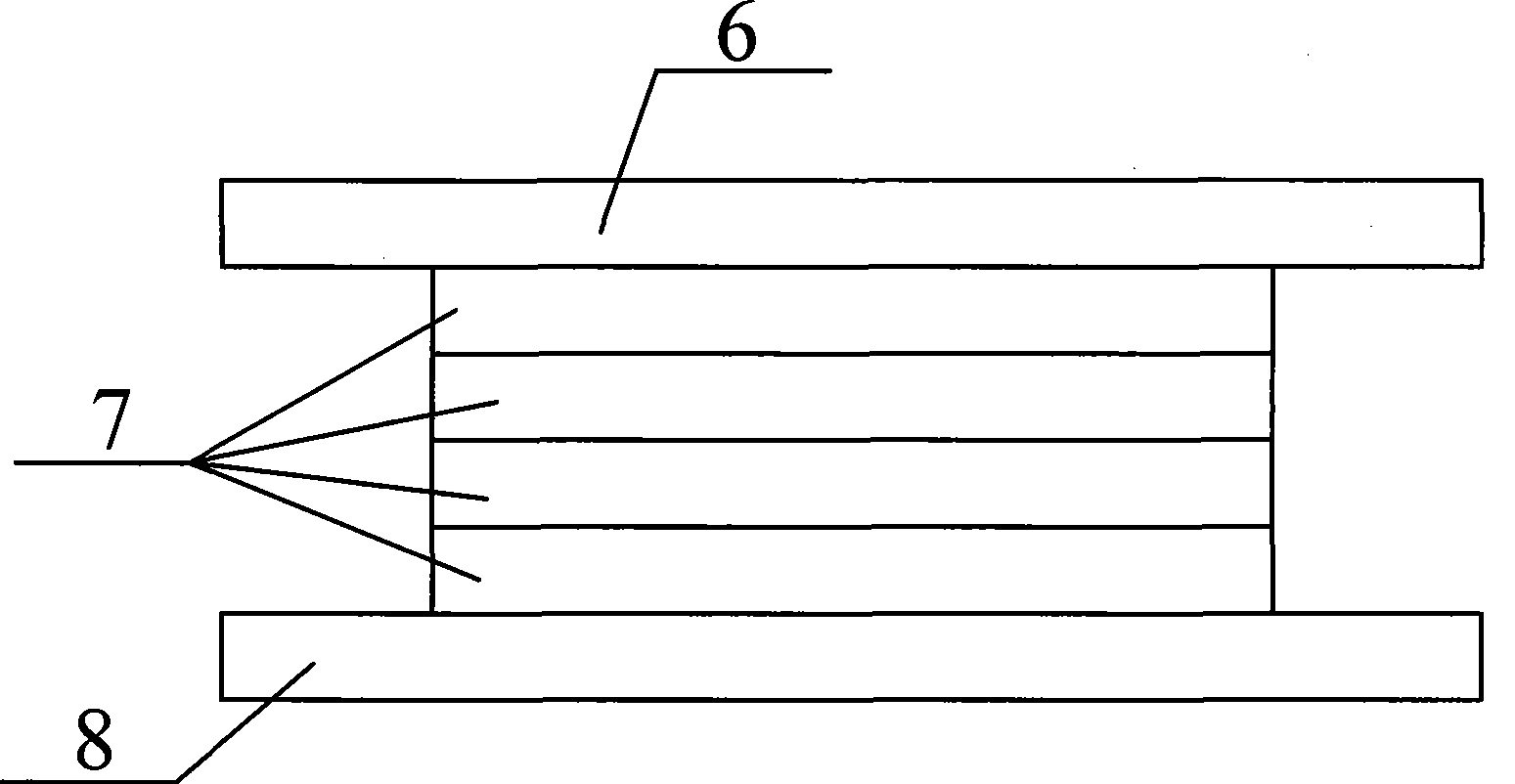

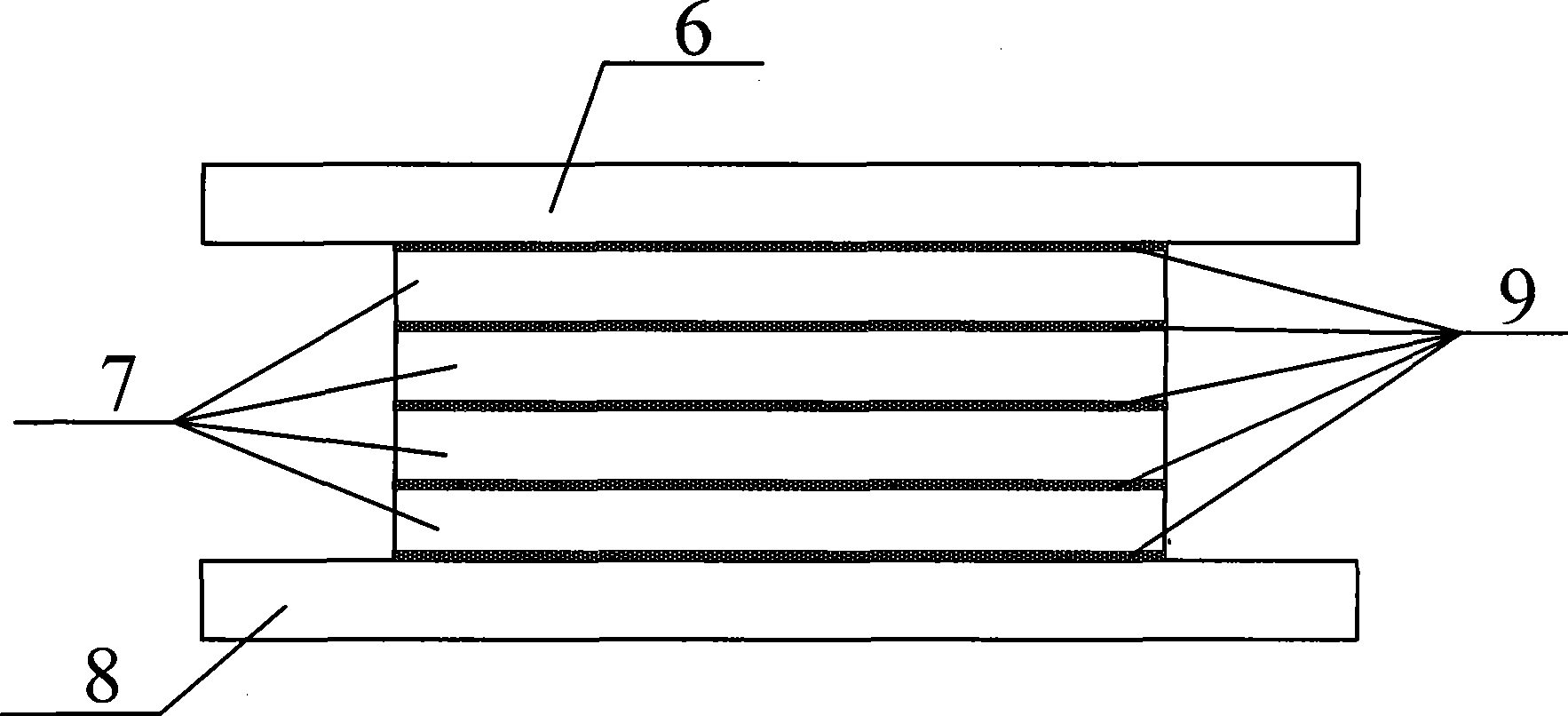

[0028] The top of the densely ribbed composite wallboard 1 with a thickness of 200-300mm is connected to the frame beam 4 through one or more slipper devices 3, and the bottom of the densely ribbed composite wallboard 1 is connected to the frame beam 4 by means of a fixed support connection , the connection method is that the steel bars reserved on the top surface of the frame beam 4 and the steel bars at the corresponding positions of the densely ribbed composite wallboard 1 are tied together, and the gap between the densely ribbed composite wallboard 1 and the frame beam 4 is 100-200 mm; The two sides are connected with the frame column 5, the gap size is 5-10mm, and the flexible filling material 2 made of polystyrene foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com