Method for carrying out earthquake-resistance and strengthening on traditional masonry structure by using steel parts

A technology of masonry structure and parts, which is applied in the direction of building structure, building maintenance, building type, etc., can solve the problems of high cost, cumbersome construction, unacceptable to the common people, etc., and achieve the advantages of convenient construction, low cost, and easy large-scale promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

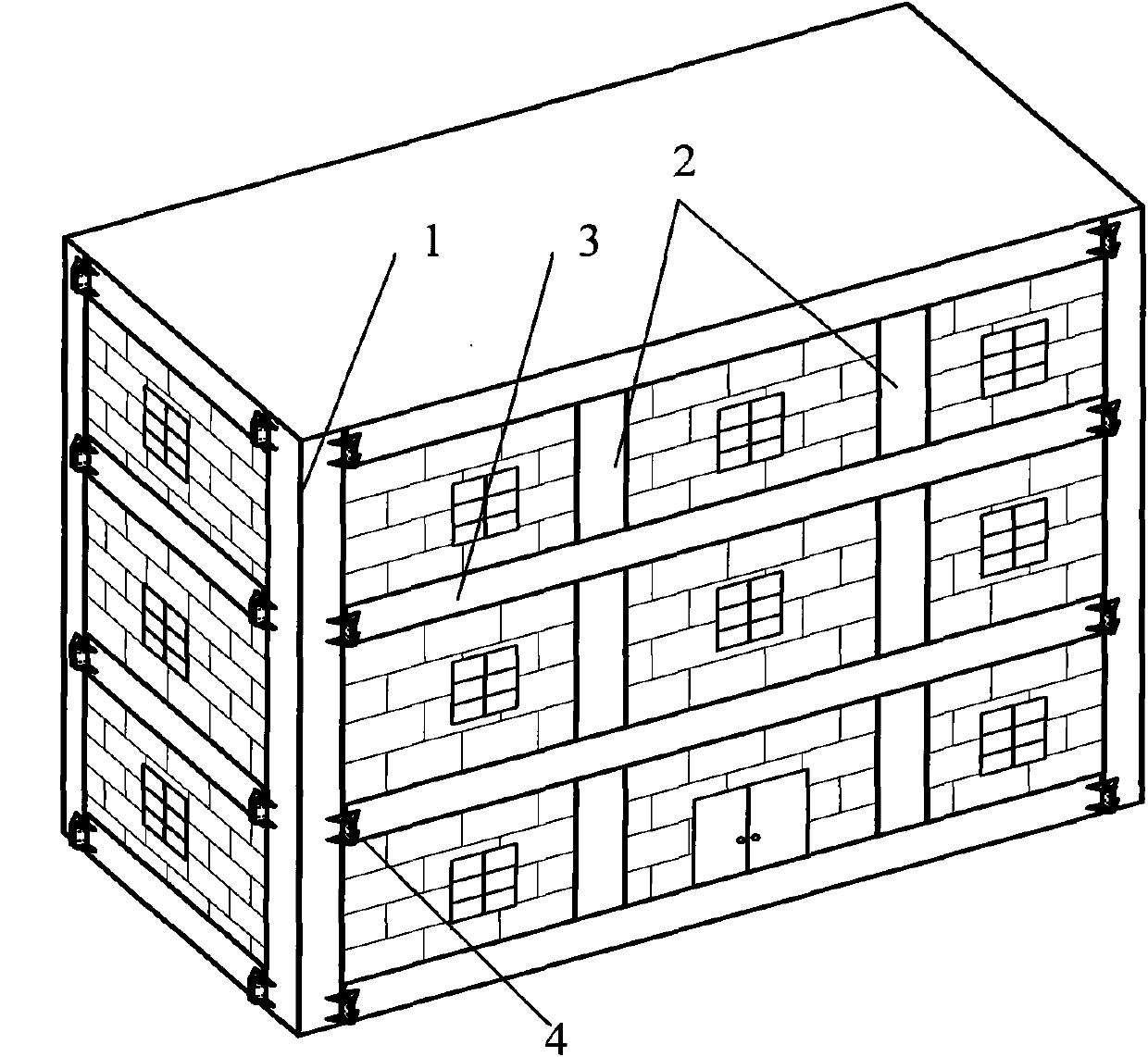

[0019] see figure 1 , a masonry structure to be reinforced has a rectangular plane of about 12m×7m, with three floors in total, the first floor is 3.5m high, and the second and third floors are 3m high. Two horizontal walls are set up, the structure adopts the load-bearing system of the horizontal wall, and the seismic fortification intensity is 7 degrees.

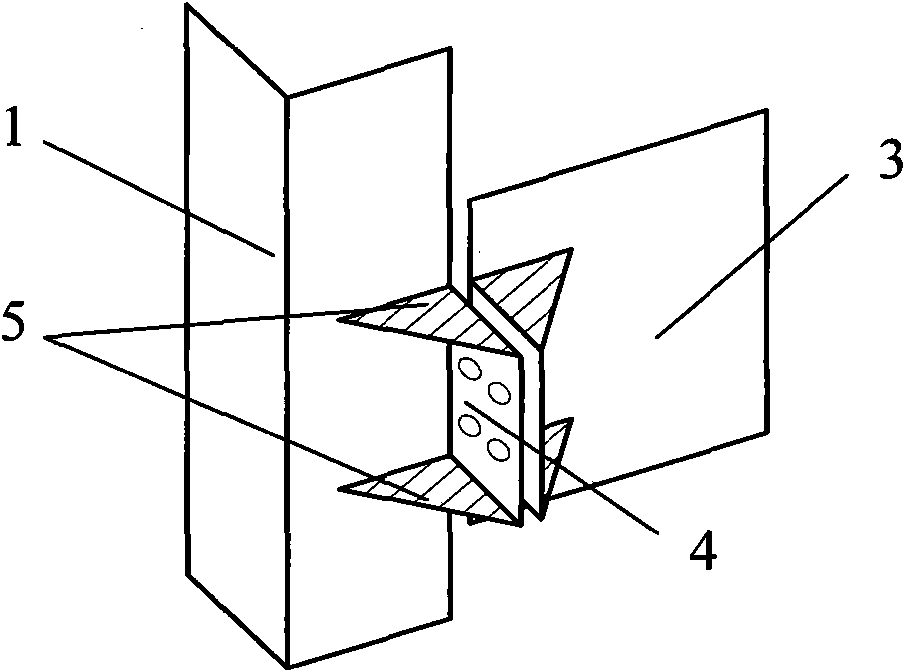

[0020] at the corner of the structure The 90×8 equilateral angle steel is used as the edge vertical steel part 1, and cement mortar is used to bond the edge vertical steel part 1 with the structure to be reinforced; Use -90×8 steel plate as the middle vertical steel part 2, and use cement mortar to bond it with the structure to be reinforced; use - 110×8 steel plate as horizontal steel pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com