Hollow double-layer FRP pipe concrete combination structure

A combined structure and concrete technology, which is applied in the field of pipe structures, can solve the problems of increasing project cost and technical difficulty, increasing component self-weight, and high maintenance costs, so as to reduce construction formwork costs and construction costs, improve strength and stiffness, and facilitate construction and installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

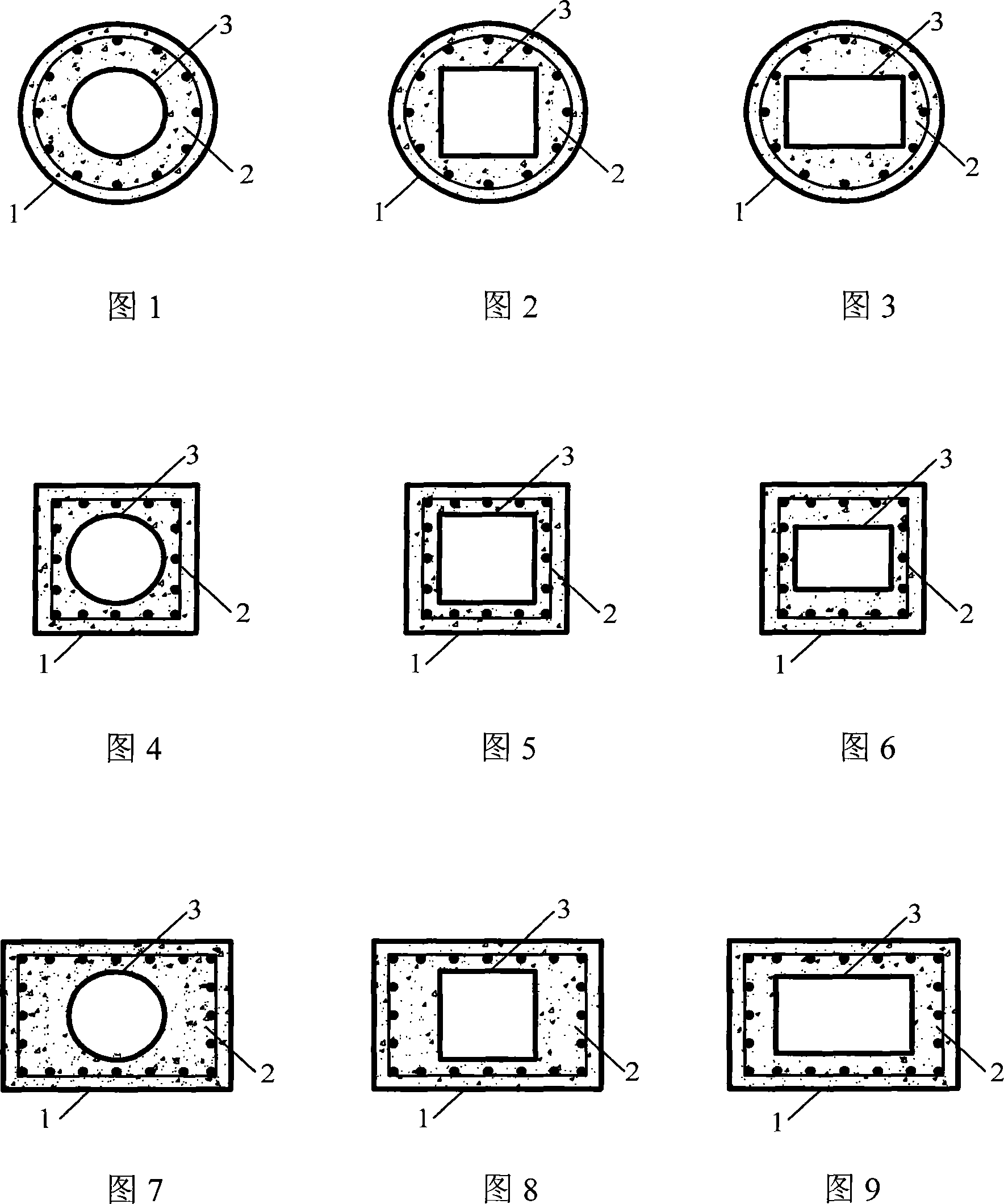

[0016] Referring to Fig. 1, the hollow pipe column is composed of an FRP outer tube 1 as the outer wall, an FRP core tube 3 as the inner wall, and a concrete layer or a reinforced concrete layer 2 consolidated between the FRP outer tube 1 and the FRP inner tube 3.

[0017] In a specific implementation, the cross-sectional form of the combined structure is any combination between the circular, square or rectangular FRP outer tube 1 and the circular, square or rectangular FRP core tube 3 . include:

[0018] Circular double-layer FRP tube concrete structure with circular sleeve shown in Fig. 1;

[0019] The circular sleeve square double-layer FRP pipe concrete structure shown in Fig. 2;

[0020] The circular sleeve rectangular double-layer FRP pipe concrete structure shown in Fig. 3;

[0021] The square sleeve circular double-layer FRP pipe concrete structure shown in Fig. 4;

[0022] The square sleeve square double-layer FRP pipe concrete structure shown in Figure 5;

[0023...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com