Tensile prestress rubber earthquake isolation support

A rubber shock-isolation bearing and prestressing technology, which is applied in the direction of shock-proof, bridge parts, bridges, etc., can solve the problems of poor tensile capacity and tensile damage, and achieve the effect of simple structure and clear shock-isolation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present invention will be further explained in conjunction with the tensile prestressed rubber shock-isolation bearing in the bearing body.

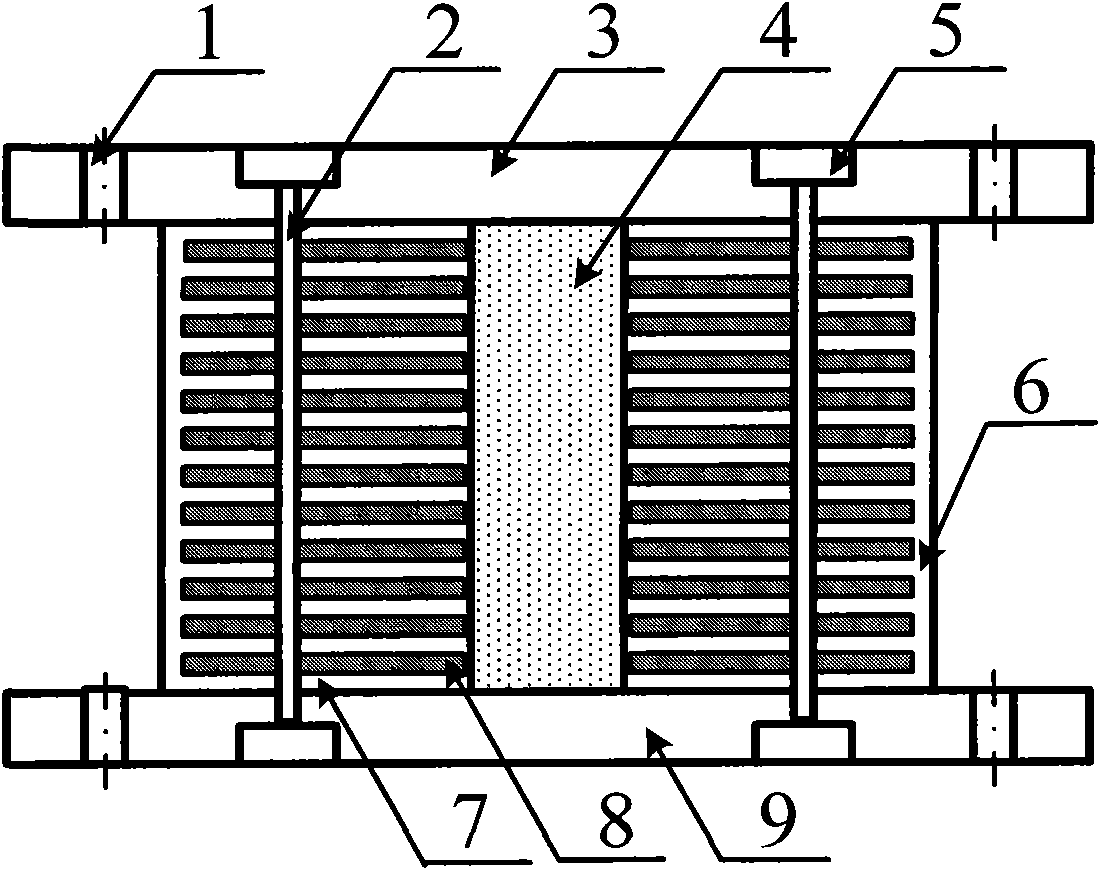

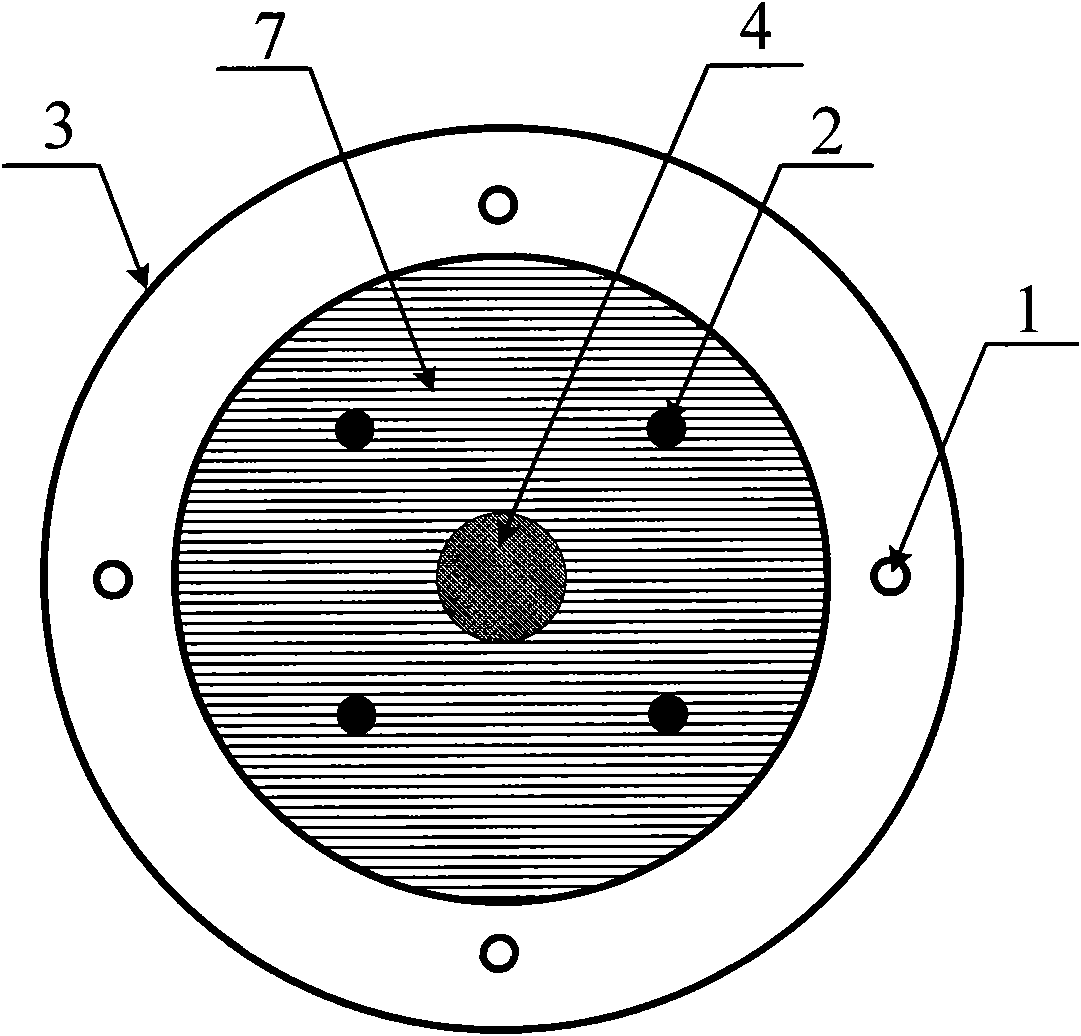

[0023] figure 1 It is a schematic diagram of the structure of the tensile prestressed rubber shock-isolation bearing in the bearing body, figure 2 It is a cross-sectional view of the tensile prestressed rubber shock-isolation bearing in the bearing body. The support is composed of upper and lower connecting steel plates 3 and 9, an inner rubber layer 7, an inner thin steel plate 8, a high-purity lead core 4, a prestressed steel strand 2 and an anchor 5, the inner rubber layer 7 and the inner thin steel plate 8 Alternately laminated to form a laminated layer, the upper and lower surfaces of the laminated layer are respectively provided with upper and lower connecting steel plates 3 and 9, the outer periphery of the laminated layer is wrapped with an external rubber protective layer 6, and the center of the laminated layer is ...

Embodiment 2

[0025] The present invention will be further described in conjunction with the outer type tensile prestressed rubber shock-isolation bearing of the bearing body.

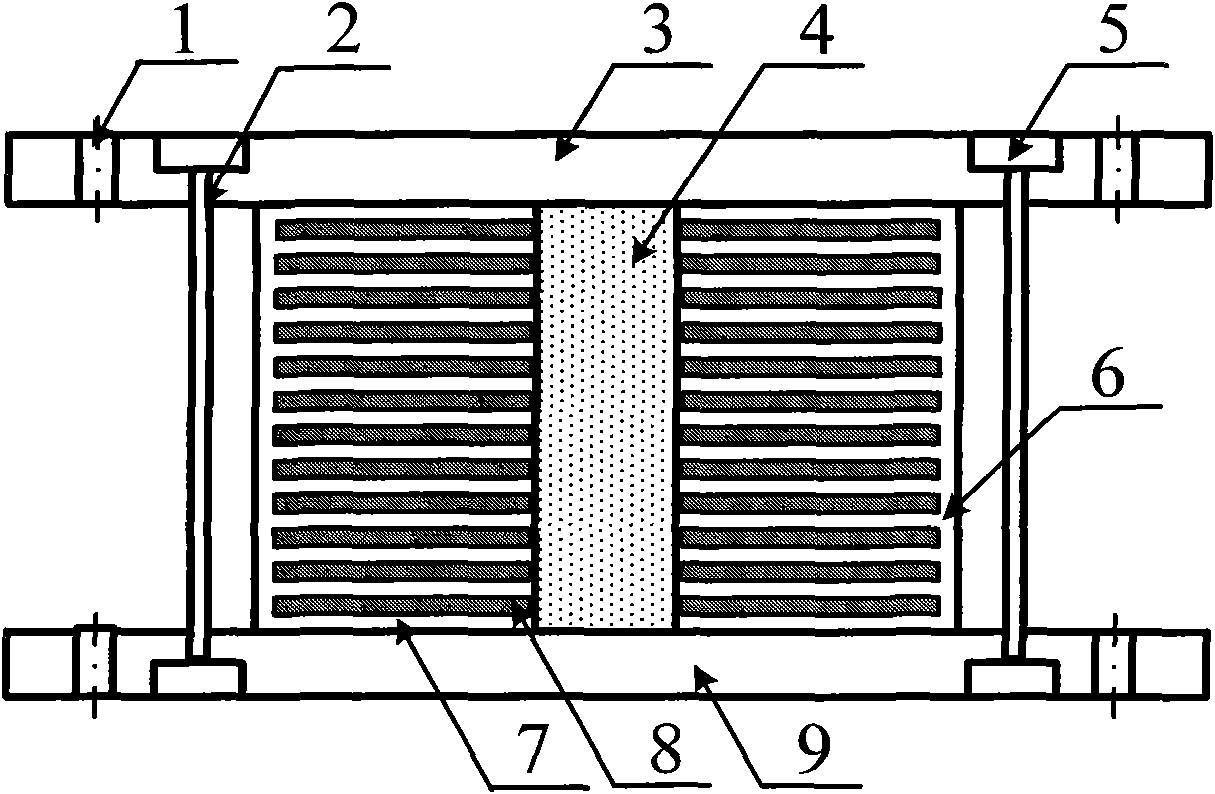

[0026] image 3 It is a schematic diagram of the structure of the external tensile prestressed rubber isolation bearing, Figure 4 It is a cross-sectional view of the external tensile prestressed rubber shock-isolation bearing of the bearing. The support is composed of upper and lower connecting steel plates 3 and 9, an inner rubber layer 7, an inner thin steel plate 8, a high-purity lead core 4, a prestressed steel strand 2 and an anchor 5, the inner rubber layer 7 and the inner thin steel plate 8 Alternately laminated to form a laminated layer, the upper and lower surfaces of the laminated layer are respectively provided with upper and lower connecting steel plates 3 and 9, the outer periphery of the laminated layer is wrapped with an external rubber protective layer 6, and the center of the laminated layer is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com