Cast-in-situ hollow floor for storing and recycling heat energy and preparation method thereof

A hollow floor and cast-in-place technology, which is applied to the improvement of building thermal performance, floor slabs, and building structures, can solve the problems of high energy consumption, low comprehensive utilization of cast-in-place hollow floors, and inflexible systems. The effect of maintaining stability and improving the anti-seismic and anti-cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

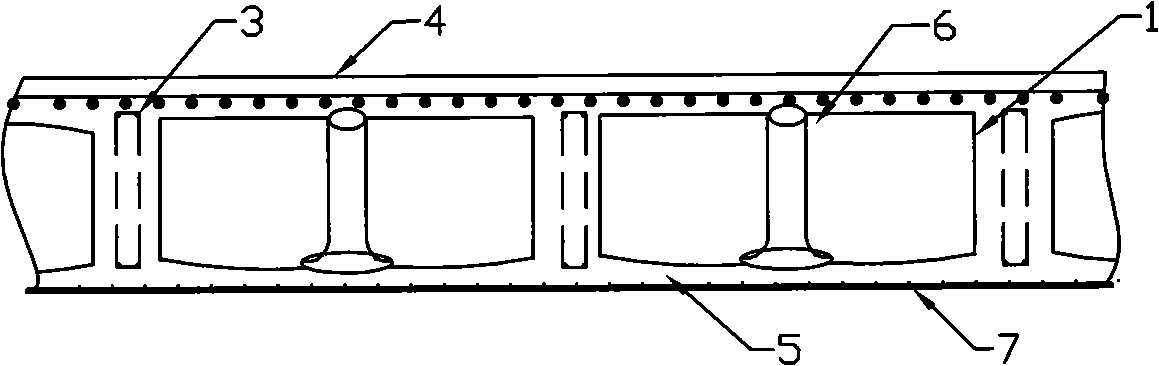

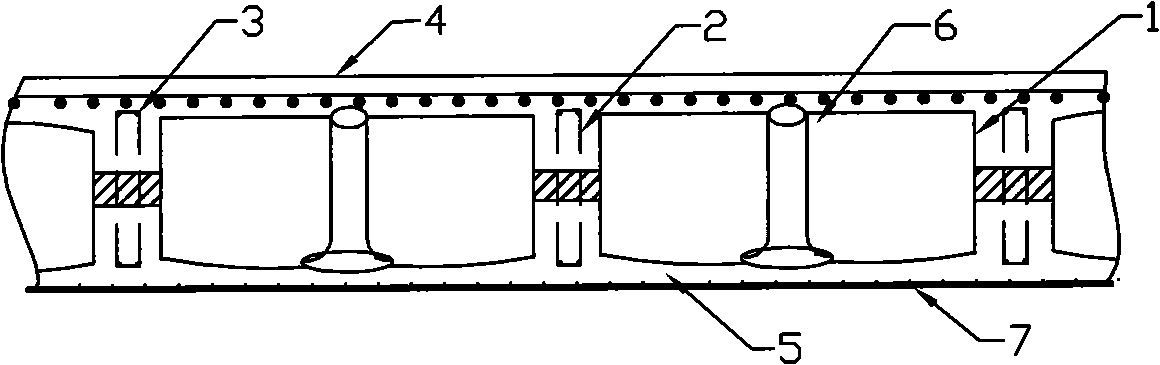

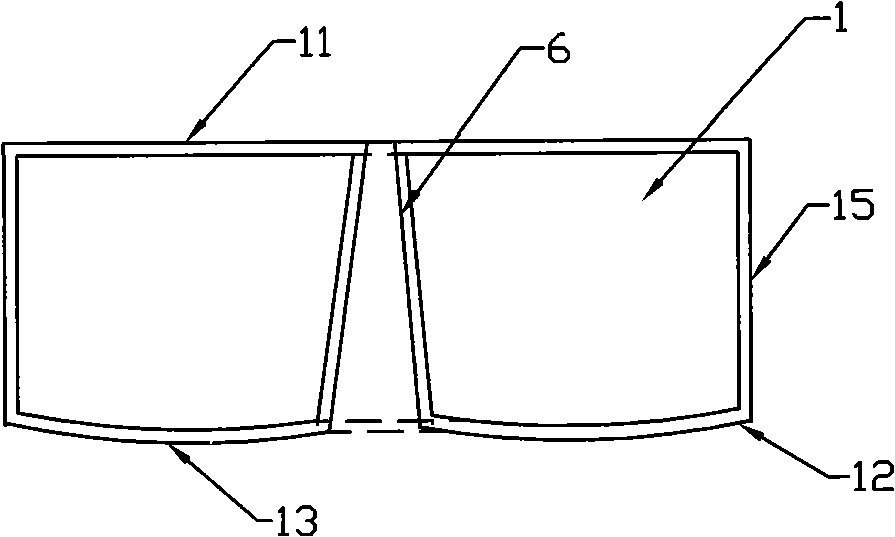

[0032] Such as figure 1 As shown, in the patent documents previously applied by the applicant, a floor structure was introduced, including a thin-walled box 1 in the middle, an upper flange plate 4, a rib beam 2, a lower flange plate 5 and a floor formwork 7 , there are multiple thin-walled boxes and they are cast-in-place with composite cement slurry or assembled from plates. The bottom plate 12 of the thin-walled box 1 has arc-shaped protrusions 13 whose height is ≤ 19 mm, and there are at least three arc-shaped protrusions on the outer surface of the bottom plate. 13, the base plate 12 and the top cover 11 have relative lower holes and upper holes, and the lower holes on the base plate are connected with the upper holes on the top cover by closing the through passage 6. The present invention will be further described below in conjunction with the accompanying drawings.

[0033] The thin-walled box used in this scheme can be made of plates separately or directly cast in plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com