Glass fiber reinforcement polyphenyl ether/polypropylene alloy and production method thereof

A polyphenylene ether and polypropylene technology, which is applied in the field of glass fiber reinforced polyphenylene ether/polypropylene alloy and its preparation, can solve the problems of unattainable physical and mechanical properties, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

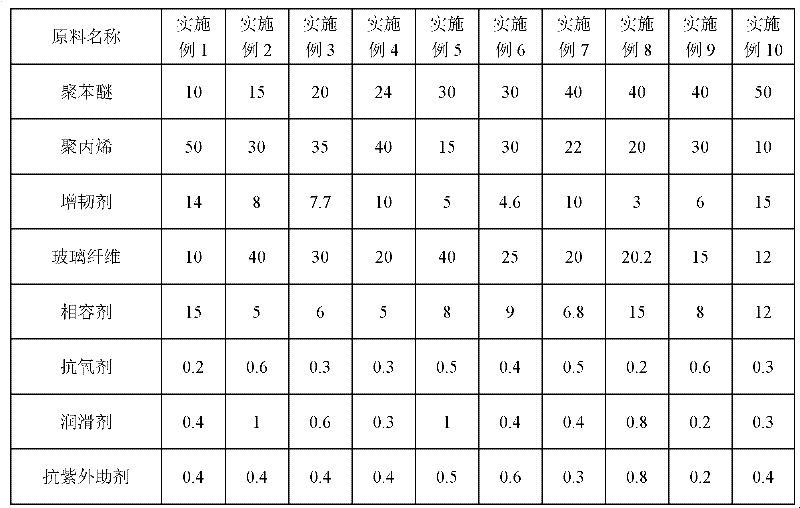

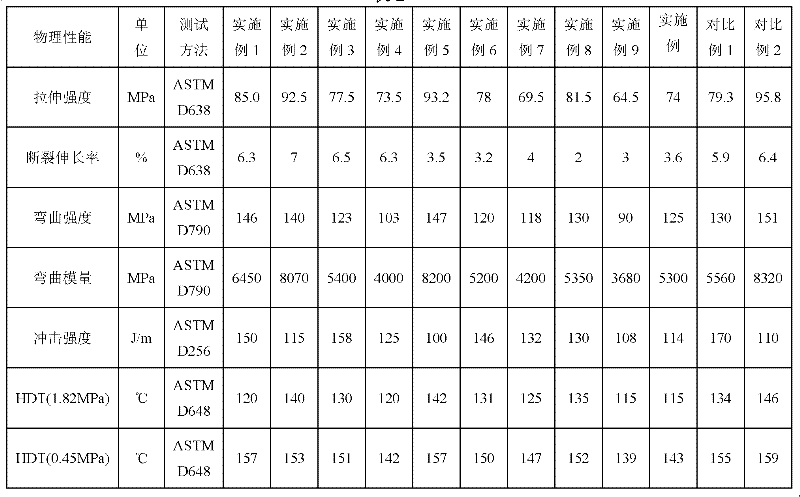

Embodiment 1

[0038] (1) Weigh raw materials according to weight ratio, PPO LXR038: 10%, polypropylene (PP): 50%, Kraton G1536: 14%, MPC1545: 15%, antioxidant: 0.2%, lubricant: 0.4%, Anti-ultraviolet additives: 0.4%.

[0039] (2) The above-mentioned mixed materials are added through the main feed of the twin-screw extruder, and the long glass fiber with a weight ratio of 10% is added through the side feed, and then extruded and granulated. The rotating speed of the screw machine is 300 rpm, and the temperature is 235°C.

Embodiment 2

[0041] (1) Weigh raw materials according to weight ratio, PPO LXR038: 15%, polypropylene (PP): 30%, Kraton G1536: 8%, MPC1545: 5%, antioxidant: 0.6%, lubricant: 1%, Anti-ultraviolet additives: 0.4%.

[0042] (2) The above-mentioned mixed materials are added through the main feed of the twin-screw extruder, and the long glass fiber with a weight ratio of 40% is added through the side feed, and then extruded and granulated. The rotating speed of the screw machine is 300 rpm, and the temperature is 235°C.

Embodiment 3

[0044] (1) Weigh raw materials according to weight ratio, PPO LXR038: 20%, polypropylene (PP): 35%, Kraton G1657: 7.7%, MPC1501: 4%, Kraton FG1901: 2%, antioxidant: 0.3%, Lubricant: 0.6%, anti-ultraviolet additive: 0.4%.

[0045] (2) The above-mentioned mixed materials are fed into the main feed of the twin-screw extruder, and the long glass fiber with a weight ratio of 30% is added through the side feed, and then extruded and granulated. The rotating speed of the screw machine is 500 rpm, and the temperature is 230°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com