Method for coarsely extracting natural borneol from cinnamomum camphora

A technology of natural borneol and borneol camphor, which is applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of cumbersome operation, high energy consumption, and small processing capacity, so as to reduce waste water discharge, reduce energy consumption, and obtain rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

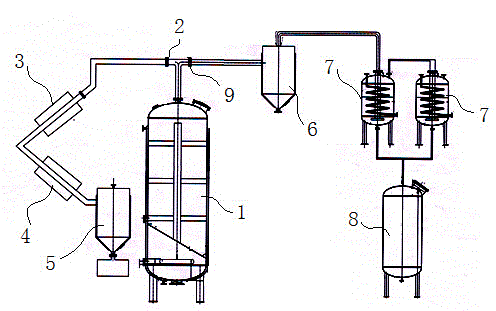

[0017] A device for crudely extracting natural borneol from borneol camphor, such as figure 1 As shown, it includes an extraction tank 1, a first valve 2, a No. 1 condenser 3, a No. 2 condenser 4, an oil-water separator 5, a gas-water separator 6, a No. 3 condenser 7 and a receiver 8. The extraction tank 1 is used to store the pulverized borneol camphor raw materials. A sight glass is arranged on the top of the extraction tank 1 for observing the extraction tank 1. Steam coils are distributed in the extraction tank 1 for heating the inside of the tank. , a heating jacket is provided outside the extraction tank 1, a material outlet is provided at the bottom of the extraction tank 1, and a steam outlet pipe is provided at the top of the extraction tank 1, and the steam outlet pipe is respectively connected with the oil-water separator 5 and the gas-water separator through pipelines. 6, a second valve 9 is provided on the pipeline connected to the gas-water separator 6, and a fir...

Embodiment 2

[0022] The method for crudely extracting natural borneol from borneol camphor is the device used in Example 1, utilizing high-pressure steam and the properties of natural borneol, and using high-pressure superheated steam to directly act on branches and leaves at 180°C. Since the boiling point of natural borneol is about 212°C, the natural borneol can be vaporized and sublimated. In a highly sealed state, condensate and crystallize through a special condenser to extract natural borneol. The specific process includes the following steps:

[0023] 1) Crush the branches and leaves of borneol camphor, the length of the crushed particles should not exceed 10cm; preferably 3-5cm.

[0024] 2) Add the crushed borneol camphor branches and leaves to the extraction tank, use high-pressure superheated steam to directly act on the branches and leaves, control the temperature at 180°C, and extract for 35-40 minutes;

[0025] 3) Use a condenser to condense the gasified natural borneol to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com