Liquid or Hydrate Power System Applied To A Single Point Injection Gas Lift System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]While the invention is susceptible to various modifications and alternative constructions, certain illustrated embodiments thereof have been shown in the drawings and will be described below in detail. It should be understood, however, that there is no intention to limit the invention to the specific form disclosed, but, on the contrary, the invention is to cover all modifications, alternative constructions, and equivalents falling within the spirit and the scope of the invention as defined in the claims. The patent worthy innovation involves making use of the temperature, pressure, and volume characteristics of phase change in order to improve the production potentials of Gas / Hydrate / Liquids to unload and produce a well by Gas / Hydrate / Liquid expansion or phase change.

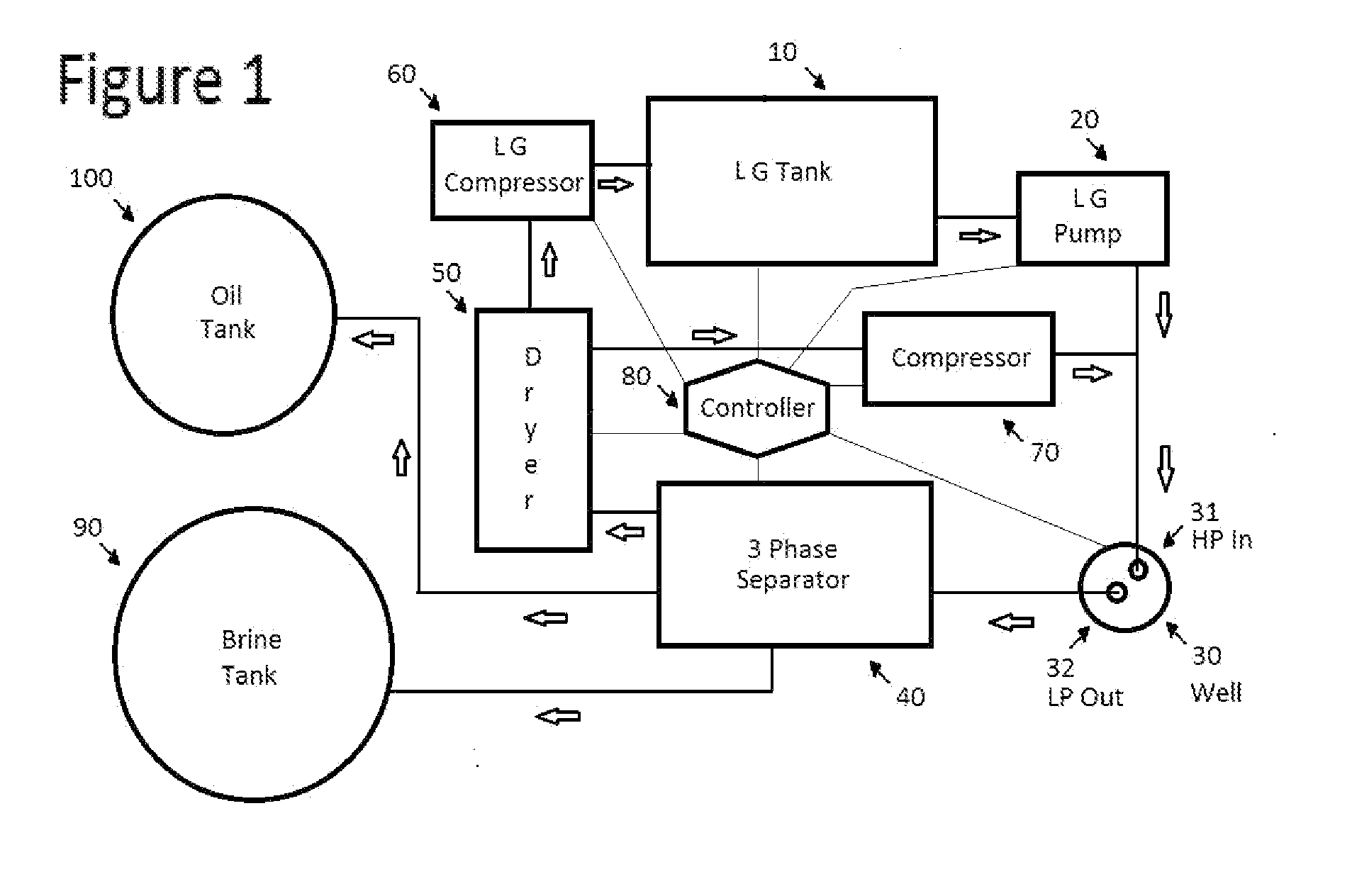

[0038]Referring in general to FIG. 1, a gas lift unloading and compression system can be constructed in accordance with the principles of the invention is seen. It is assumed that the down-hole mandrel can be any...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com