Engineering strain expressing acid-resistant high-temperature alpha-amylase gene mutants

A technology of engineering strains and amylases, applied in genetic engineering, plant genetic improvement, microorganism-based methods, etc., can solve the problems of low enzyme activity and single strain, and achieve the effect of strong acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

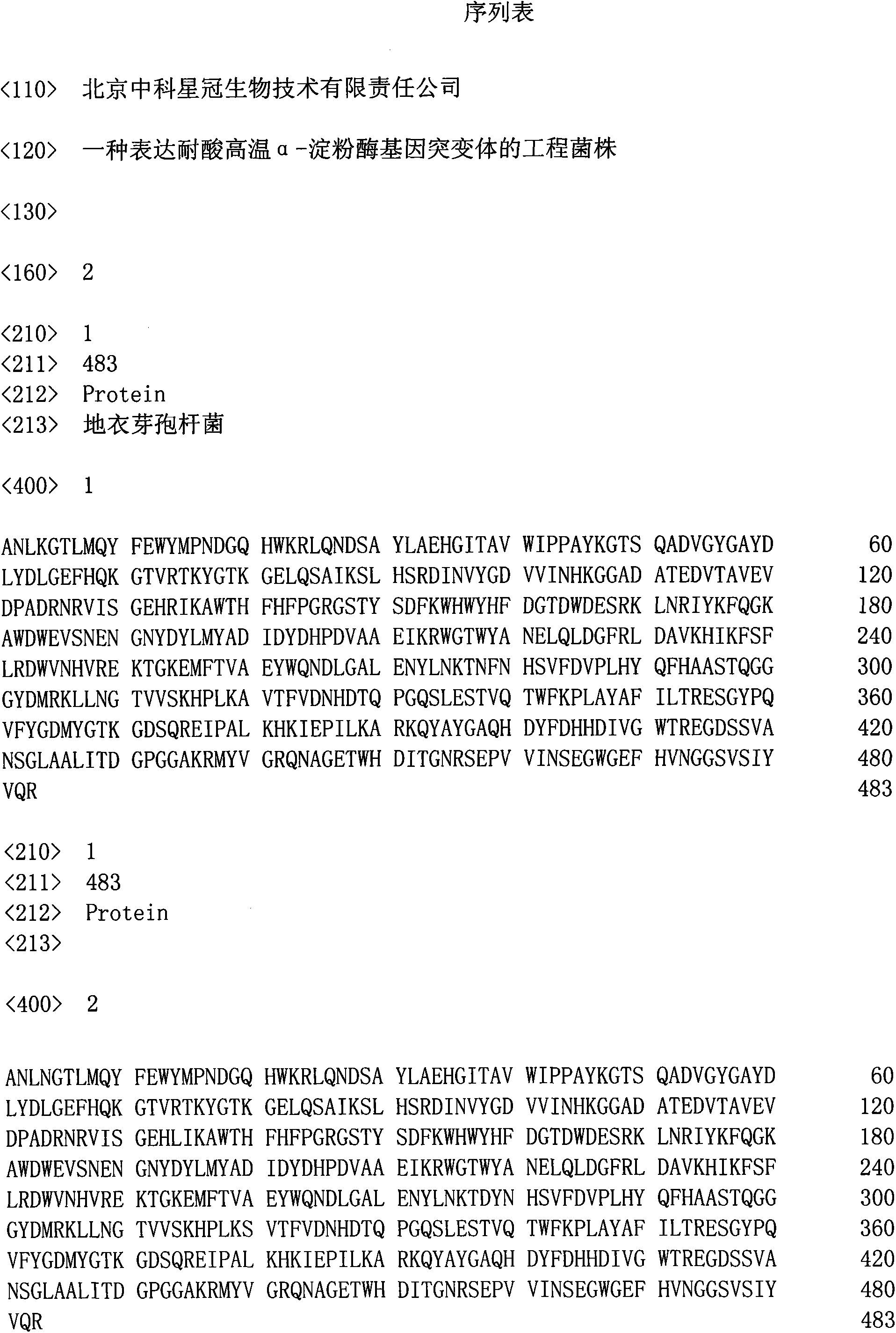

[0016] Example 1. Sodium nitrite mutagenesis to obtain acid-resistant high-temperature α-amylase mutant gene amyM

[0017] Genomic DNA of Bacillus licheniformis CICC10181 (purchased from China Industrial Microorganism Culture Collection Center) was extracted. (Extraction method refers to Bron, S (1990). Plasmids. In Molecular Biological Methods for Bacillus, pp75-174. Edited by C.R. Harwood & S.M. cutting. Chichester: Wiley).

[0018] Using Bacillus licheniformis (B.Licheniformis) CICC10181 genomic DNA as a template for PCR amplification of amy gene, the upstream primer is primer 1 (5'-ACCTGCCTGTACACTTGCG-3') and the downstream primer is primer 2 (5'-CTCTCTGCTCTTCTATCTTTG-3') .

[0019] Amplification conditions: pre-denaturation at 94°C for 5 minutes, then denaturation at 94°C for 1 minute, annealing at 56°C for one minute, extension at 72°C for 1 minute and 30 seconds. After completing 30 cycles, it was incubated at 72° C. for 10 minutes.

[0020] The amy fragment of 1978b...

Embodiment 2

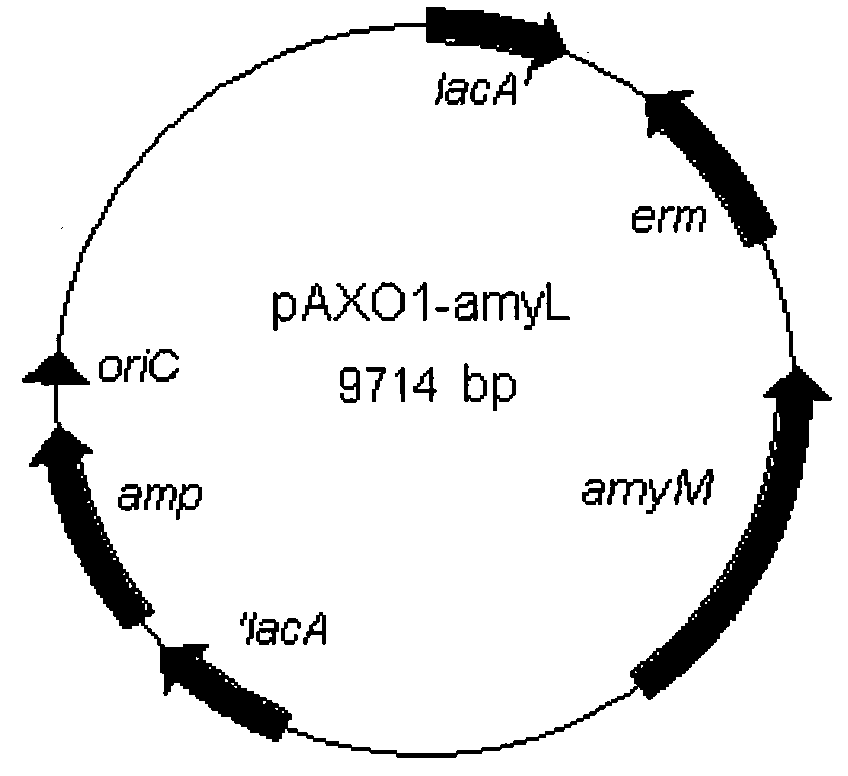

[0031] Example 2. Construction of the shuttle vector pAXOI-amyl carrying the LacA integration arm expressing the acid-resistant high-temperature α-amylase mutant gene amyM

[0032] The plasmid pEASY-T3-amyM was used as a template to amplify the acid-resistant and high-temperature α-amylase mutant gene amyM by PCR. The amplification primer is: upstream primer 5'-cg ggatcc ACCTGCCTGTACACTTGCG-3' (the underlined part is the BamHI restriction site) and downstream primer 5'tccat ccgcgg -CTCTCTGCTCTTCTATCTTTG-3' (the underlined part is SacII, restriction site).

[0033]The amyM fragment of 1978bp was obtained from the above amplification, and sequencing showed that the fragment included the promoter of the acid-resistant high-temperature alpha-amylase gene, the signal peptide coding sequence and the structural gene.

[0034] The PCR product amyM and the shuttle integration plasmid pAXOI (purchased from the Ohio State University Culture Collection Center, Bacillus Genetic Stock C...

Embodiment 3

[0035] Embodiment 3, the construction of engineering bacteria ZHWY expressing acid-resistant high-temperature α-amylase gene mutant

[0036] The expression shuttle integration plasmid pAXOI-amyM carrying the promoter, signal peptide and structural gene of acid-resistant high-temperature amylase obtained by mutagenesis in Example 2 was electroporated with protoplasts (Romero D, Journal of Microbiology Methods, 2006 Vol66p556-559 ) to transform Bacillus licheniformis CICC10181 (purchased from the China Industrial Microbiology Culture Collection Management Center, the preservation number is CICC10181) producing high-temperature starch, and the specific method is as follows:

[0037] After the Bacillus licheniformis CICC10181 protoplasts were obtained using the Romero D Bacillus licheniformis protoplast preparation method (Romero D, Journal of Microbiology Methods, 2006Vol66p556-559), take 5ul (2ug) of the purified plasmid pAXOI-amyM in a 1.5ml centrifuge Put it and the 0.2CM elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com