Method for short-term production of isotropic superfine structure isostatic pressing formed graphite

An isotropic and fine-structure technology, which is applied in the field of isostatic graphite with isotropic ultra-fine structure in a short process, can solve the problems of high discharge consumption, low pass rate, high cost, etc., and achieve excellent use effect and uniform temperature Improvement of performance and shortening of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

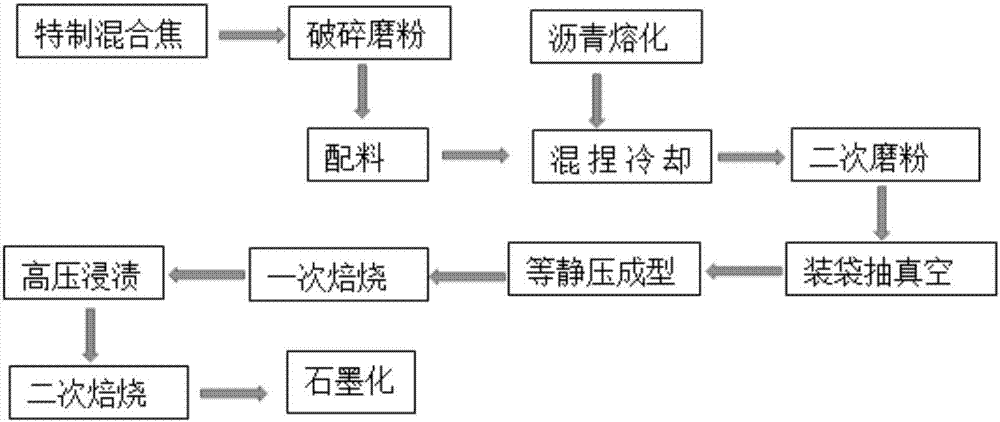

[0014] Attached below in conjunction with the instructions figure 1 The present invention is further explained.

[0015] A short-process method for producing isostatically pressed graphite with homogeneous ultrafine structure. The processing process is: crushing mixed coke, primary grinding → batching → pitch melting → mixing and cooling → secondary grinding → bagging vacuum → isostatic Compression molding→primary roasting→high pressure impregnation→secondary roasting→graphitization.

[0016] Asphalt melting uses high-temperature modified asphalt as a binder.

[0017] The primary grinding particle size is 8μm, and it is formed on a Φ1500mm*4200mm isostatic press. The size of the green body is 1660mm*830mm*390mm, and the green body density is 1.53---1.55g / cm 3 .

[0018] The primary roasting adopts positive pressure roasting in a trolley furnace, the qualification rate of primary roasting reaches 99.5%, and the density of the first roasted product reaches 1.66---1.68g / cm 3 , The compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com