A simulation validation method for virtualization dispatching optimization in process industry

A technology for optimal scheduling and simulation verification, which is applied in the field of simulation verification of virtual optimal scheduling in the process industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

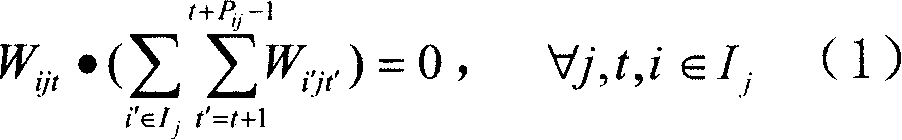

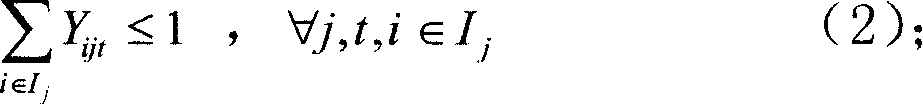

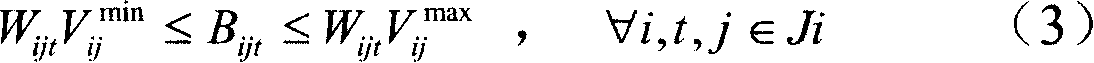

[0032] A method for simulation verification of process industry simulation optimization scheduling, the specific steps are:

[0033] (1) Scheduling plan generation: According to product sales plan, raw material procurement plan, equipment maintenance plan, product (intermediate, raw material) inventory information and equipment production capacity, production resource occupation, consumption, production cost and other production constraint information, generate a target model The mathematical model of optimal scheduling is established based on the data files, and the optimal scheduling scheme is calculated according to the optimization goals set by the user (maximum production capacity, maximum profit, or satisfying sales orders) and the model solver.

[0034] (2) Predict possible production abnormalities through calculation: collect the current product sales plan, raw material procurement plan (including arrival status), inventory information, equipment maintenance plan, energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com