Dual compounding cryogen refrigeration system with a precooling function and method

A refrigeration system and composite refrigerant technology, applied in the direction of refrigeration and liquefaction, liquefaction, solidification, etc., can solve the problems of rising natural gas, increasing raw material costs, and decreasing profit margins of liquefaction plants, and achieves small effective energy loss, uniform temperature difference, and system The effect of rich adjustment means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention uses multi-stage precooler evaporators for precooling, and the more stages used for precooling (that is, the number of precooler evaporators), the more energy consumption is saved. But from the perspective of operation and economic investment, level 4 is the most reasonable. Using four-stage pre-cooling can save 10% of the power of the pre-cooling compressor compared with three-stage pre-cooling. Therefore, the present invention will be described in detail by taking the four-stage precoolant evaporator as an example:

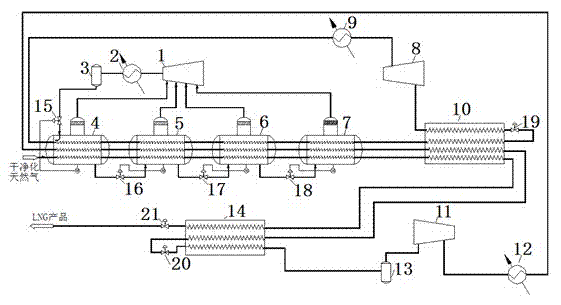

[0029] A dual compound refrigerant refrigeration system with precooling, such as figure 1 As shown, including: precoolant compressor 1, precoolant cooler 2, precoolant separator 3, high pressure precoolant evaporator 4, medium pressure precoolant evaporator 5, low pressure precoolant evaporator 6 , Low and low pressure precoolant evaporator 7, MR1 compressor 8, MR1 cooler 9, liquefaction main low temperature heat exchanger 10, MR2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com