Jacking bidirectional width adjusting mechanism

A technology of width adjustment and jacking, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as cumbersome operation, increased equipment cost, and inability to meet modern concepts, and achieve high transmission efficiency and low friction loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

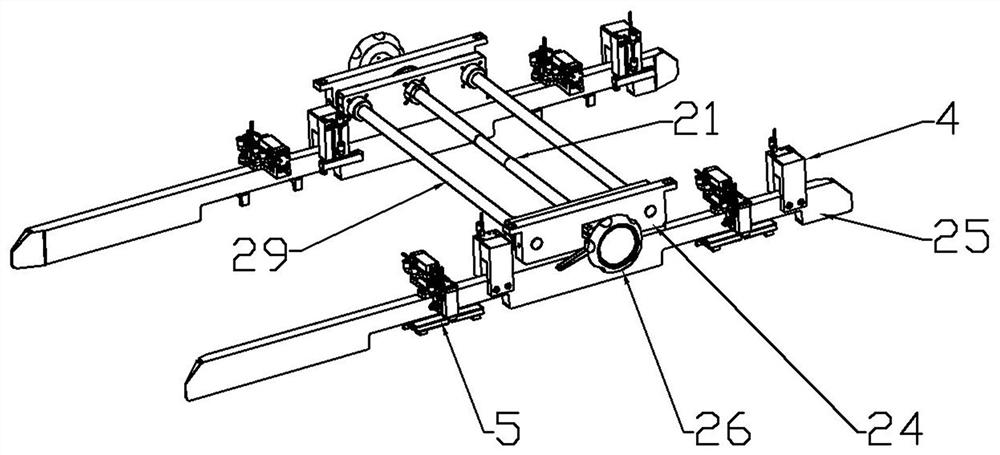

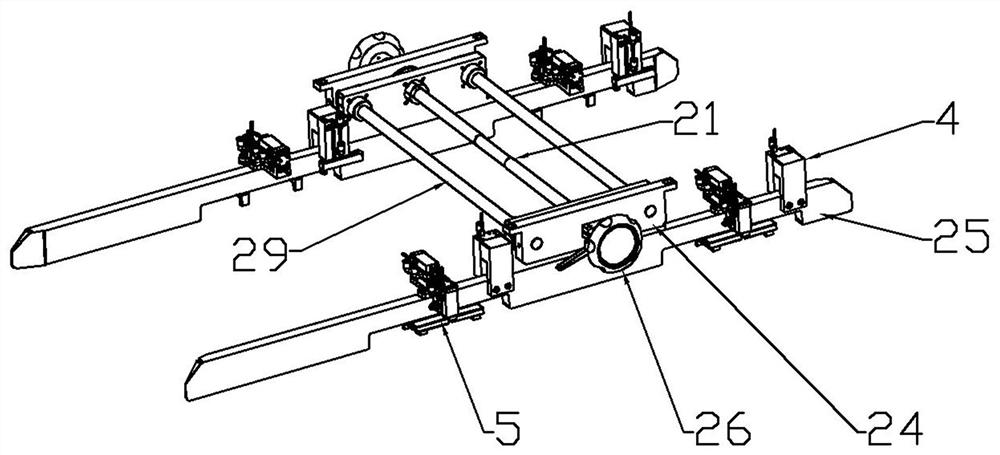

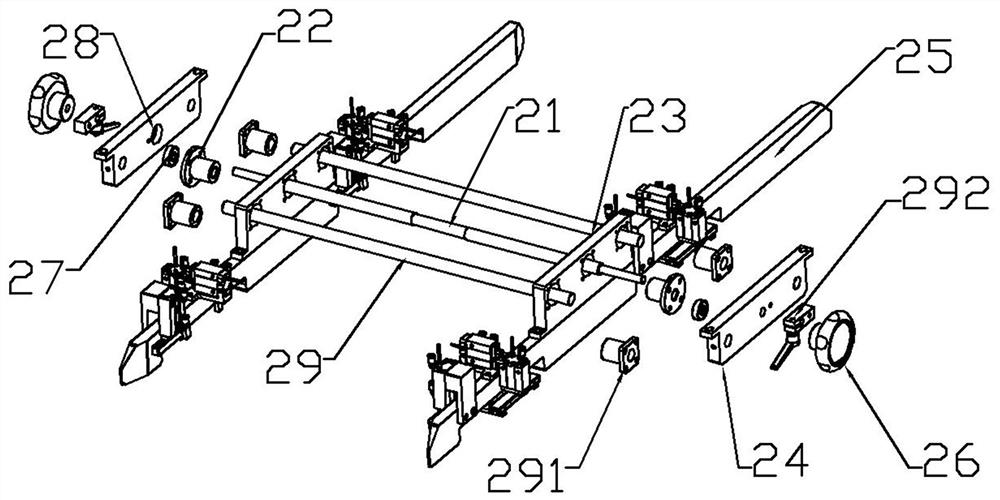

[0034] Such as Figure 1 to Figure 10As shown, in this embodiment, the present invention includes a track line module 1, a width adjustment module 2 and a jacking module 3, and the width adjustment module 2 includes a screw 21 and a width adjustment structure, and the width adjustment structure It includes a ball nut 22, a connection block 23, a first fixed block 24 and a rib 25, the ball nut 22 passes through the connection block 23 and is fixed on the outside of the connection block 23, and one end of the screw rod 21 passes through the Through the ball nut 22 and the first fixed block 24, the rib 25 is fixed on the connecting block 23 and parallel to the transport direction of the track line module 1, and the end of the screw rod 21 is set There is a handle 26, and the number of the width-adjusting structures is two groups, and the two groups of the width-adjusting structures are respectively arranged at the two ends of the screw rod 21 and located on both sides of the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com