Reliability test platform for radial hydrostatic bearing

A technology of hydrostatic bearing and test bench, used in mechanical bearing testing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

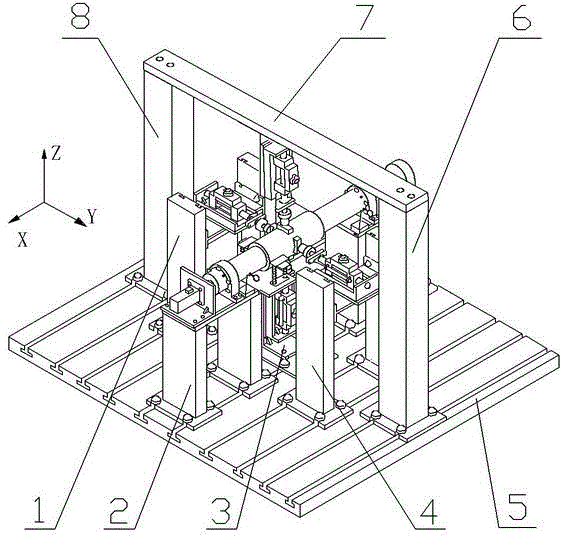

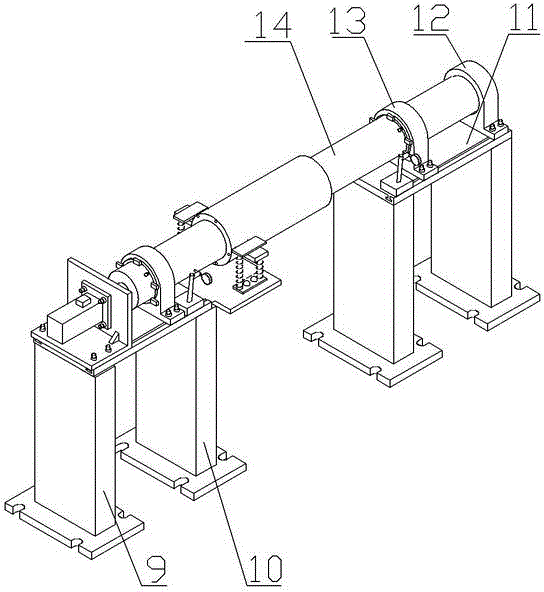

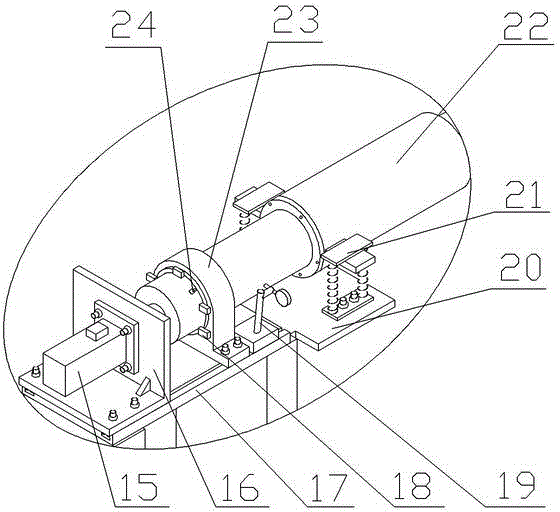

[0066] refer to figure 1 As shown, the present invention includes test bench support, radial hydrostatic bearing auxiliary device, Z positive loading device, Z negative loading device, Y positive loading device, Y negative loading device and automatic control device;

[0067] For the positive and negative directions of X, Y, and Z described in the present invention, refer to figure 1 As shown in the coordinate system, the direction pointed by the arrow in the coordinate system is the positive direction of the corresponding coordinate axis, otherwise it is the negative direction.

[0068] 1. Test bench support

[0069] refer to figure 1 As shown, the test bench is supported by a horizontal iron 5, the horizontal iron 5 is placed horizontally, and the T-shaped slots are distributed along the X direction, and are used to support the radial hydrostatic bearing auxiliary device 2 fixedly arranged in the X direction , a Y positive loading device 1 arranged in the Y direction, a Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com