Radial loading device of multifunctional bearing testing machine

A loading device and axial loading technology, which is applied in mechanical bearing testing, measuring devices, testing of mechanical components, etc., to achieve the effects of easy disassembly, simple operation, and convenient loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following specific examples describe the purpose of the present invention in further detail, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

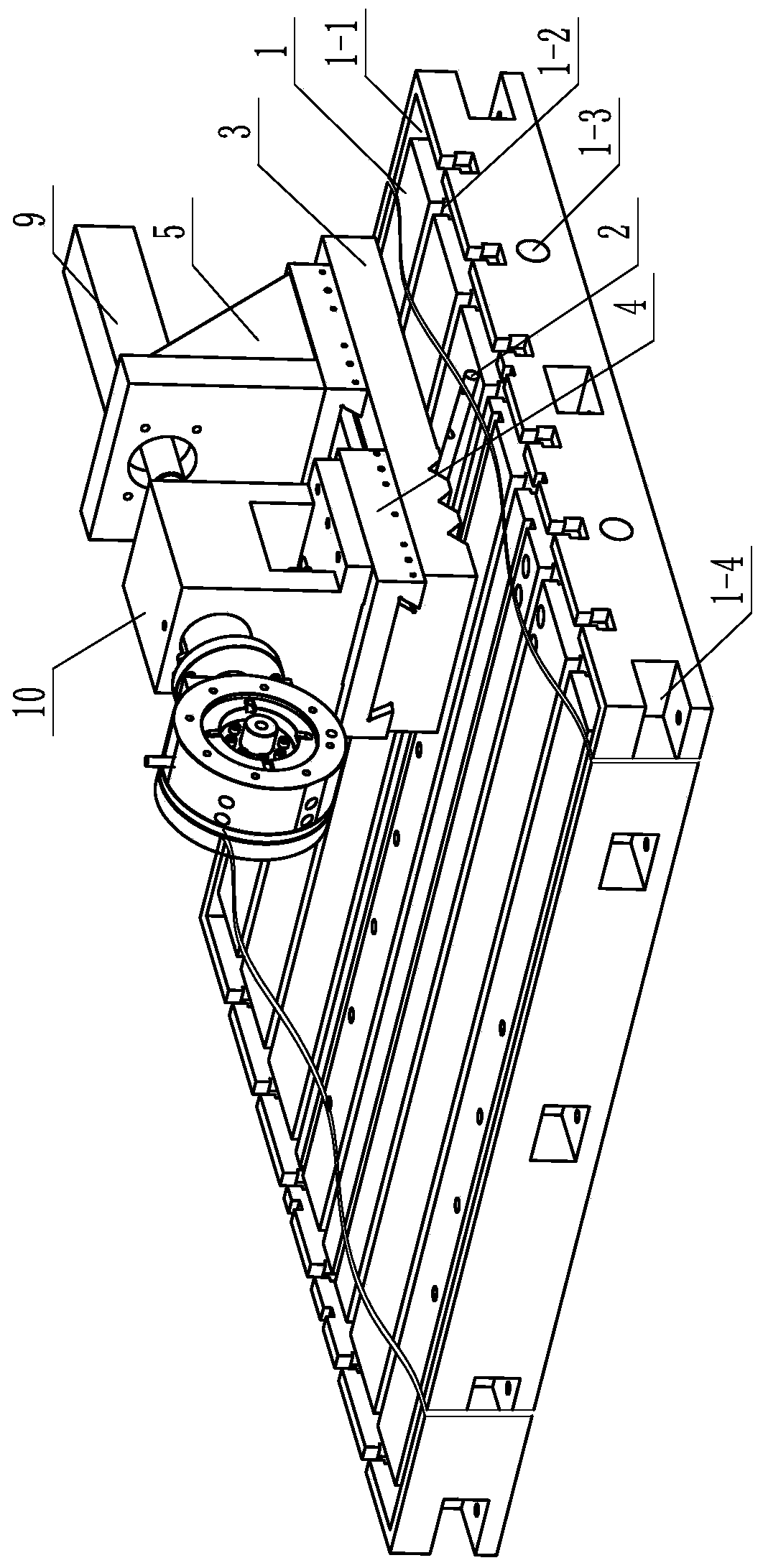

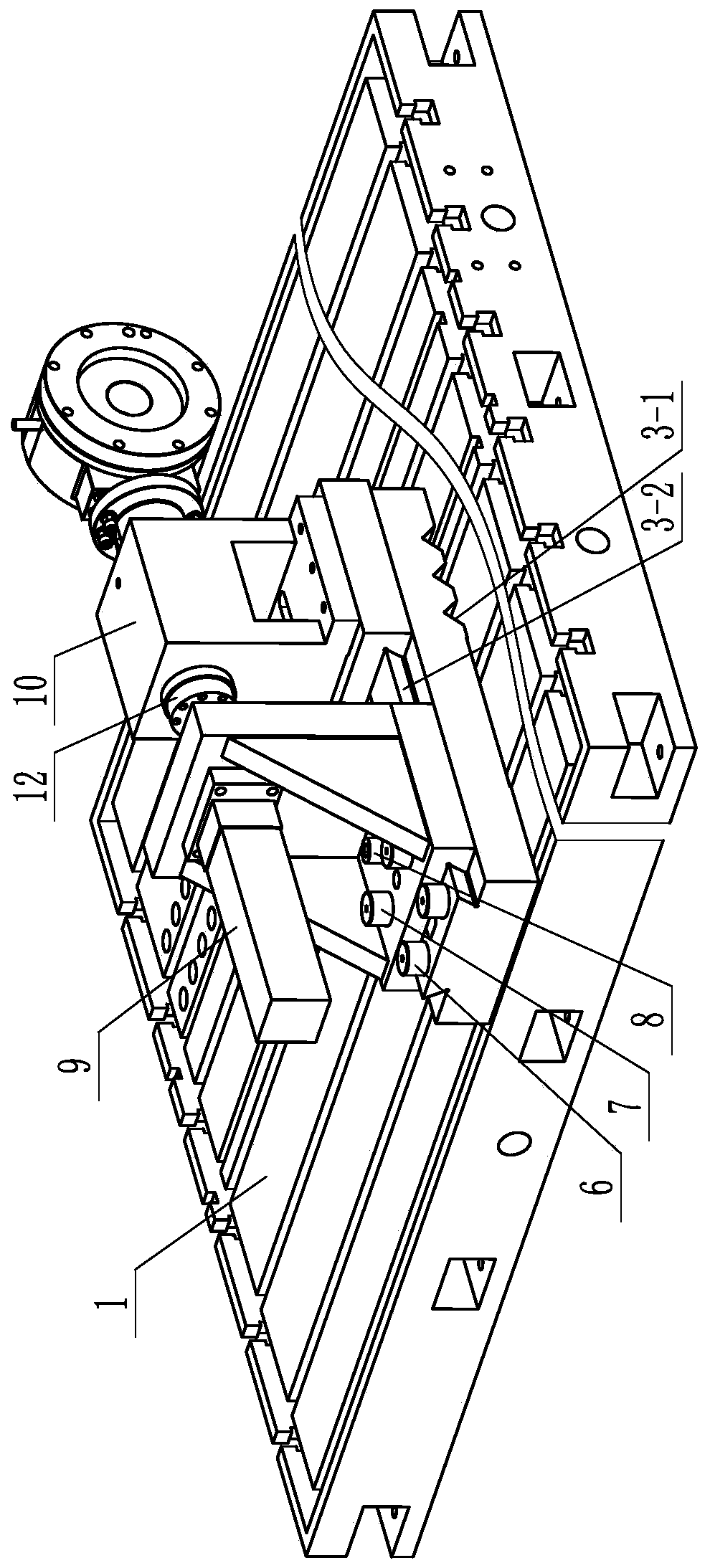

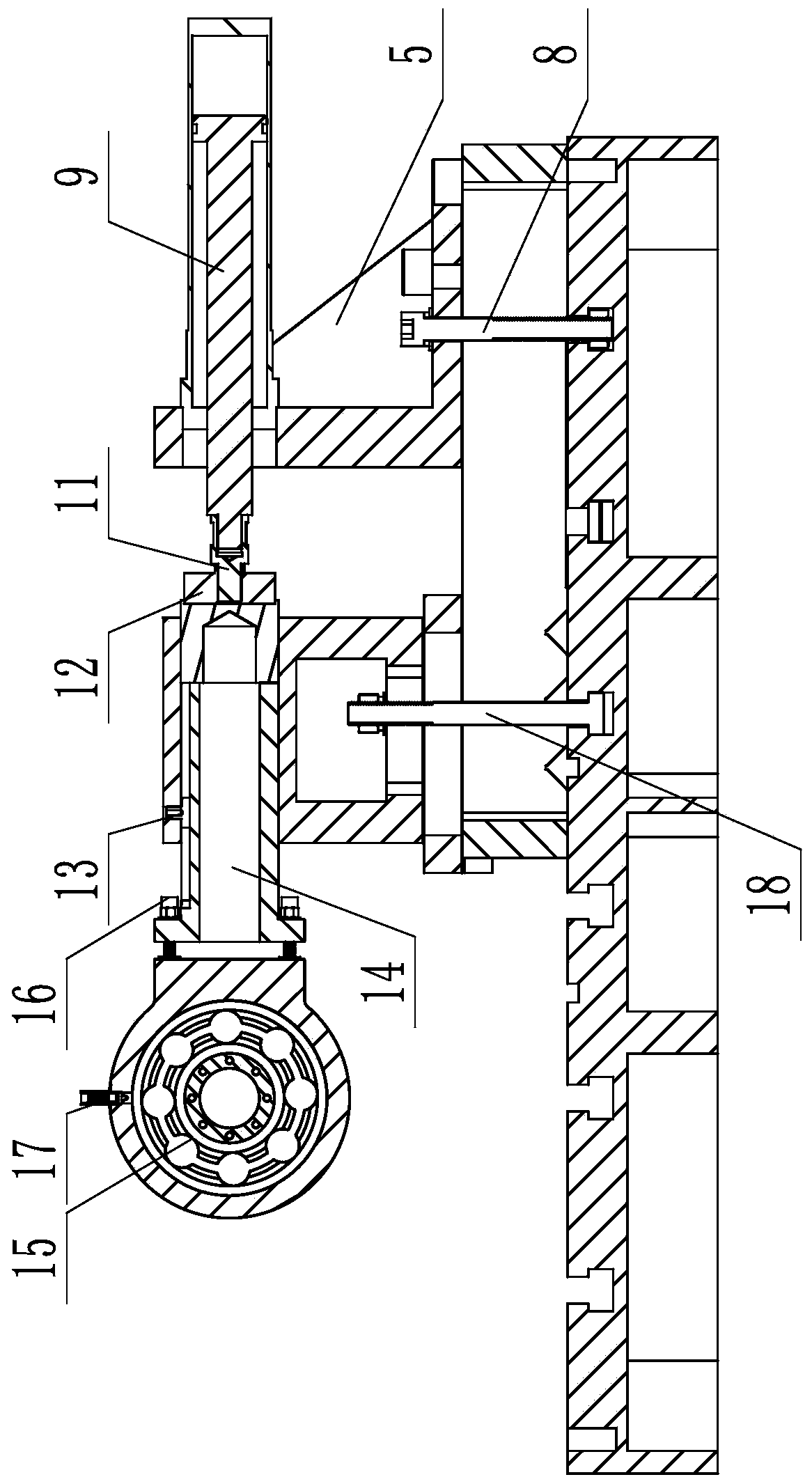

[0021] Refer to attached figure 1 to attach Figure 5 , a radial loading device for a multifunctional bearing testing machine, including a base plate 1, a guide rail 2, a radial loading seat 3, an axial guide seat 4, a loading cylinder mounting seat 5, a mounting seat positioning pin 6, and a mounting seat connecting bolt 7 , Mounting seat T-shaped locking bolt 8, axial loading cylinder 9, front guide seat 10, coupling 11, pressure sensor 12, anti-rotation pin 13, force shaft 14, bearing test installation tool 15, tool connecting bolt 16 1. Sensor mounting assembly 17 and front guide seat fixing T-shaped bolts 18 are characterized in that: the base plate 1 is fixed on the ground by anchor bolt grooves 1-4, and the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com