Triaxial test pressure chamber capable of simulating unloading and supporting of underground caverns and tunnel excavation

A technology of excavation unloading and triaxial test, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., which can solve the difference of stress path and cannot simulate the excavation unloading and support of underground caverns protection, can not simulate the excavation and unloading of underground caverns and tunnels, etc., to achieve the effect of simple operation process, simple loading method and good simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

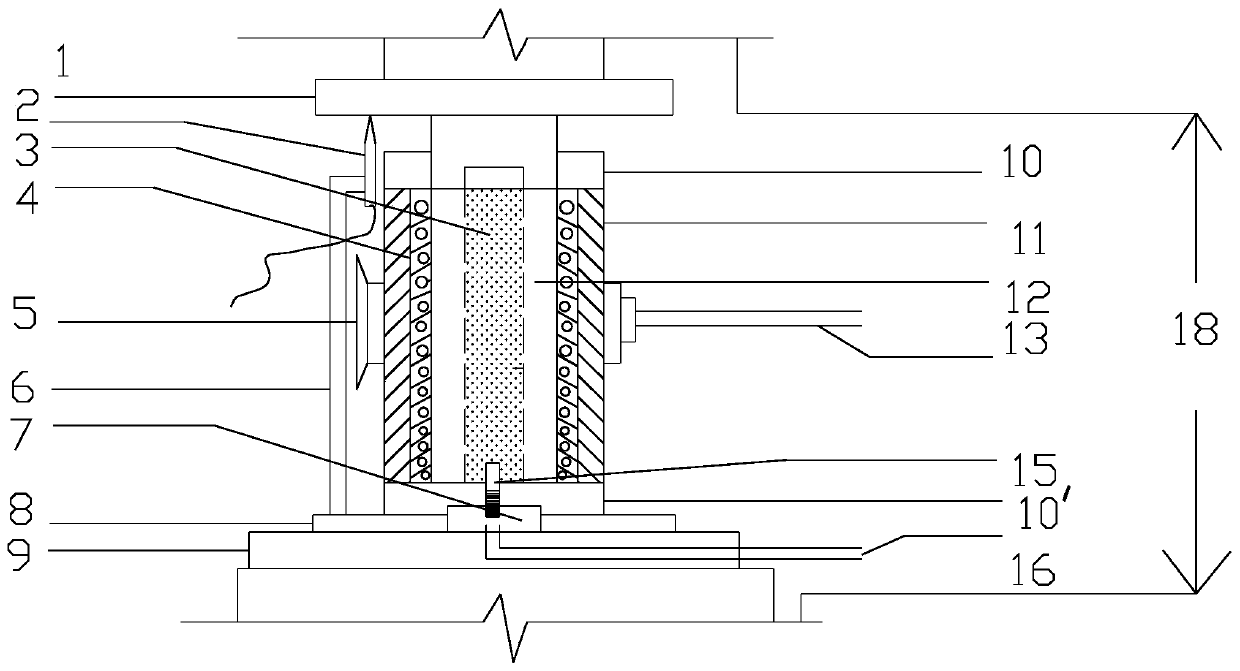

[0032] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

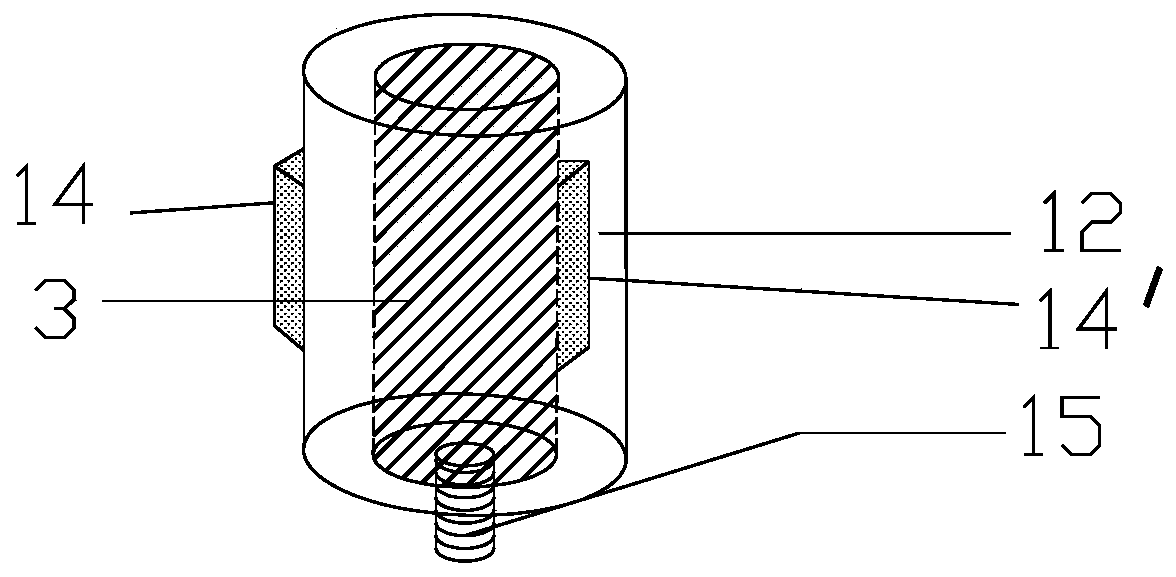

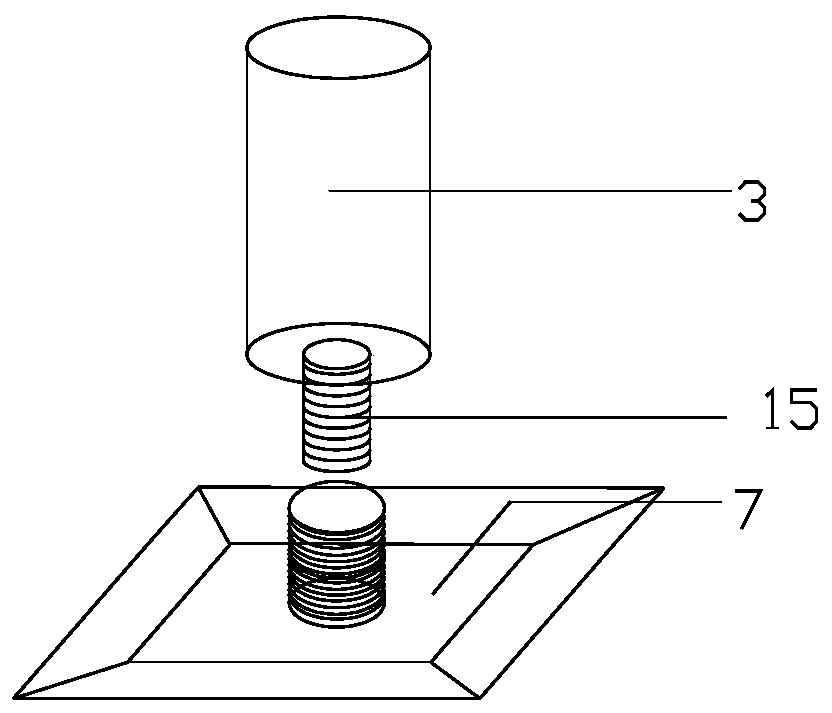

[0033] (1): the diameter of triaxial test rock sample sample should be 48mm~54mm, and the ratio of sample height and diameter should be 2.0~2.5, and the rock sample that generally uses is diameter 50mm, height 100mm, take this as an example to the present invention A multifunctional triaxial test pressure chamber is described. Such as figure 2 As shown in , a circular hole with a diameter of 10-40 mm is drilled in the center of the standard rock sample with a drilling machine. At this time, the preparation of sample 12 is completed.

[0034] (2): The first strain gauge 14 and the second strain gauge 14' are attached to the middle of the contact between the outside of the sample 12 and the outer hydraulic sleeve 4, and the contact between the inside of the sample 12 and the inner hydraulic sleeve 3, respectively. The middle. A resistance strain ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com