Dynamic self-check method of safety light curtain

A technology of dynamic self-inspection and safety light curtain, which is applied to the driving device of forging presses, etc., can solve the problems of poor anti-interference ability, failure to recognize the correct signal of the optical path, difficulty in self-inspection signal transmission and reliability, and achieve anti-interference Strong ability, simple structure, and the effect of breaking foreign monopoly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

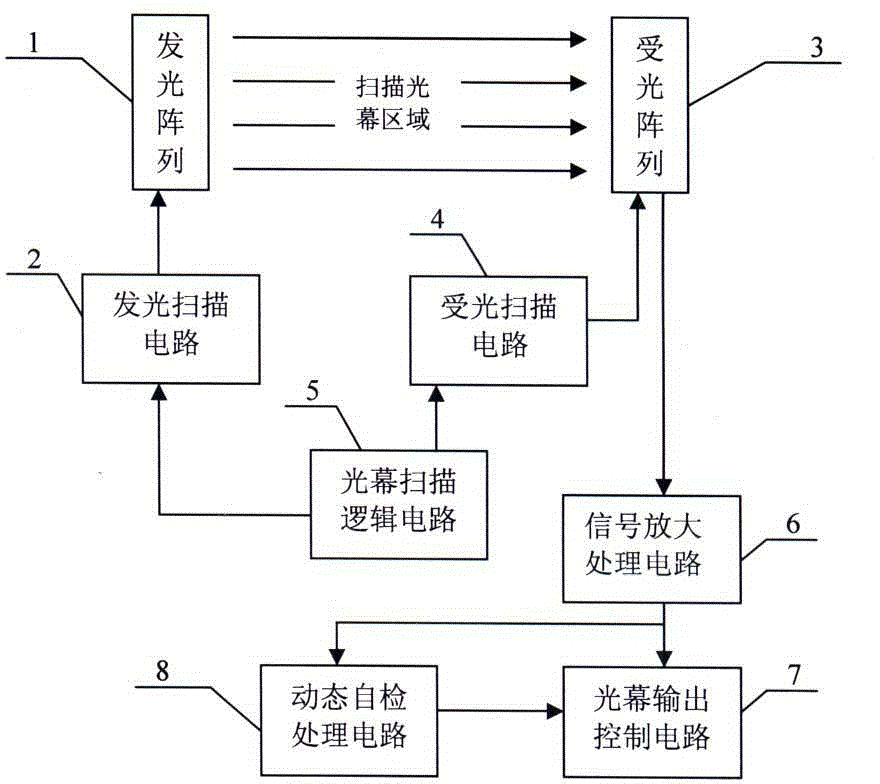

[0011] Reference figure 1 The present invention includes a light-emitting array 1, a light-emitting scanning circuit 2, a light-receiving array 3, a light-receiving scanning array 4, a light curtain scanning logic circuit 5, a signal amplification processing circuit 6, a light curtain output control circuit 7 and a dynamic self-check processing circuit 8. The photoelectric protection sensor circuit, the light-emitting scanning signal output terminal of the light curtain scanning logic circuit 5 is connected to the light-emitting scanning circuit 2, the output terminal of the light-emitting scanning circuit 2 is connected to the light-emitting array 1, and the light-receiving scanning signal output terminal of the light curtain scanning logic circuit 5 Connected to the light-receiving scanning circuit 4, the output end of the light-receiving scanning circuit 4 is connected to the light-receiving array 3, the light-emitting array 1 and the light-receiving array 3 form a scanning li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com