Constant speed control system of concrete mixing and transporting vehicle

A mixing transport vehicle, constant speed control technology, applied in the direction of control devices, clay preparation devices, cement mixing devices, etc., can solve the problems of difficult wide application, high price, etc., to reduce energy consumption, reduce production costs, ensure homogeneity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

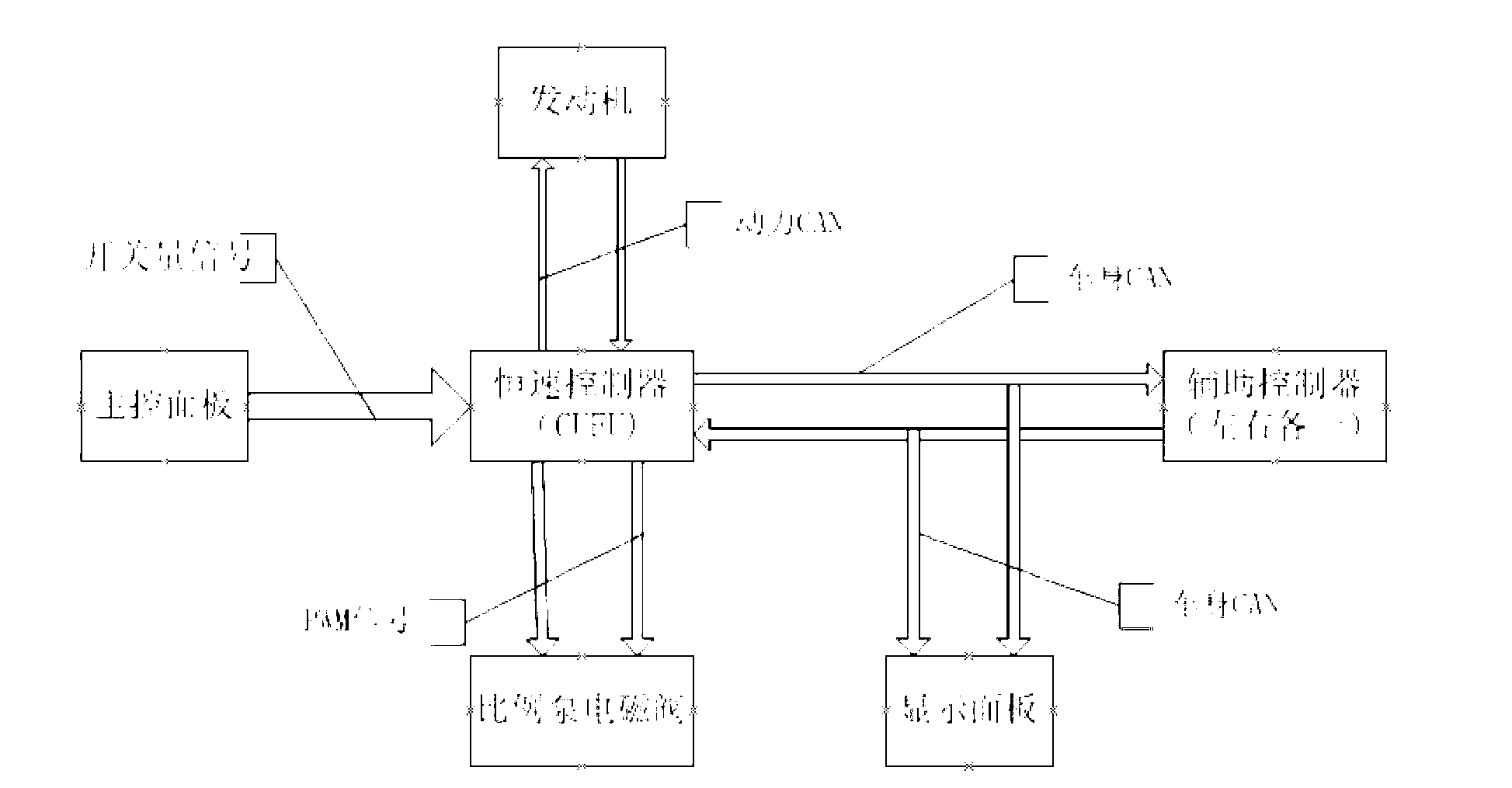

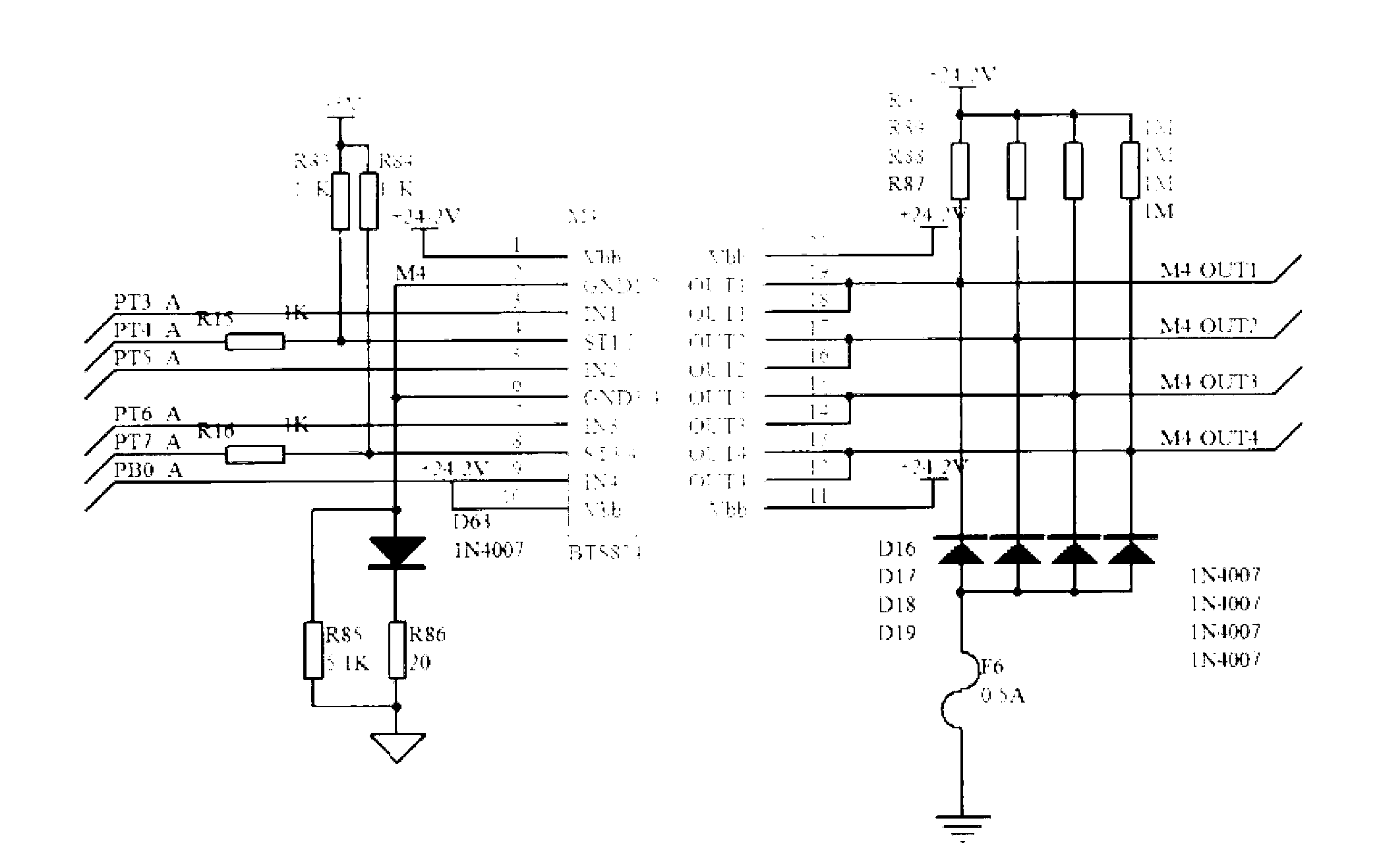

[0019] Example: such as Figure 1-2 As shown, it is a specific embodiment of a constant speed control system for a concrete mixer truck of the present invention, which includes a constant speed controller connected to the engine through a power bus, a main control unit connected to the constant speed controller, and a constant speed controller connected to the constant speed controller. The auxiliary control unit connected to the speed controller, the display unit used to display the operation status of the main control unit in real time, the variable pump solenoid valve connected to the constant speed controller, the hydraulic drive unit controlled by the variable pump solenoid valve, and the agitation detection unit. Rotary speed sensor for drum speed. Among them, the structure constant speed controller, main and auxiliary control units are connected through the body bus of the F-CAN bus platform, and the communication protocol includes communication speed, length of communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com