Heat exchanger structure

A technology of heat exchangers and spiral tubes, which is applied in the field of heat exchanger structure of gas fully premixed condensing wall-hung boilers, can solve the problem that the thermal efficiency of gas fully premixed condensing wall-hung boilers cannot meet the requirements and the localization of heat exchangers Difficulty in production, difficulty in manufacturing heat exchanger products, etc., to achieve the effect of simple structure, easy production and manufacturing, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

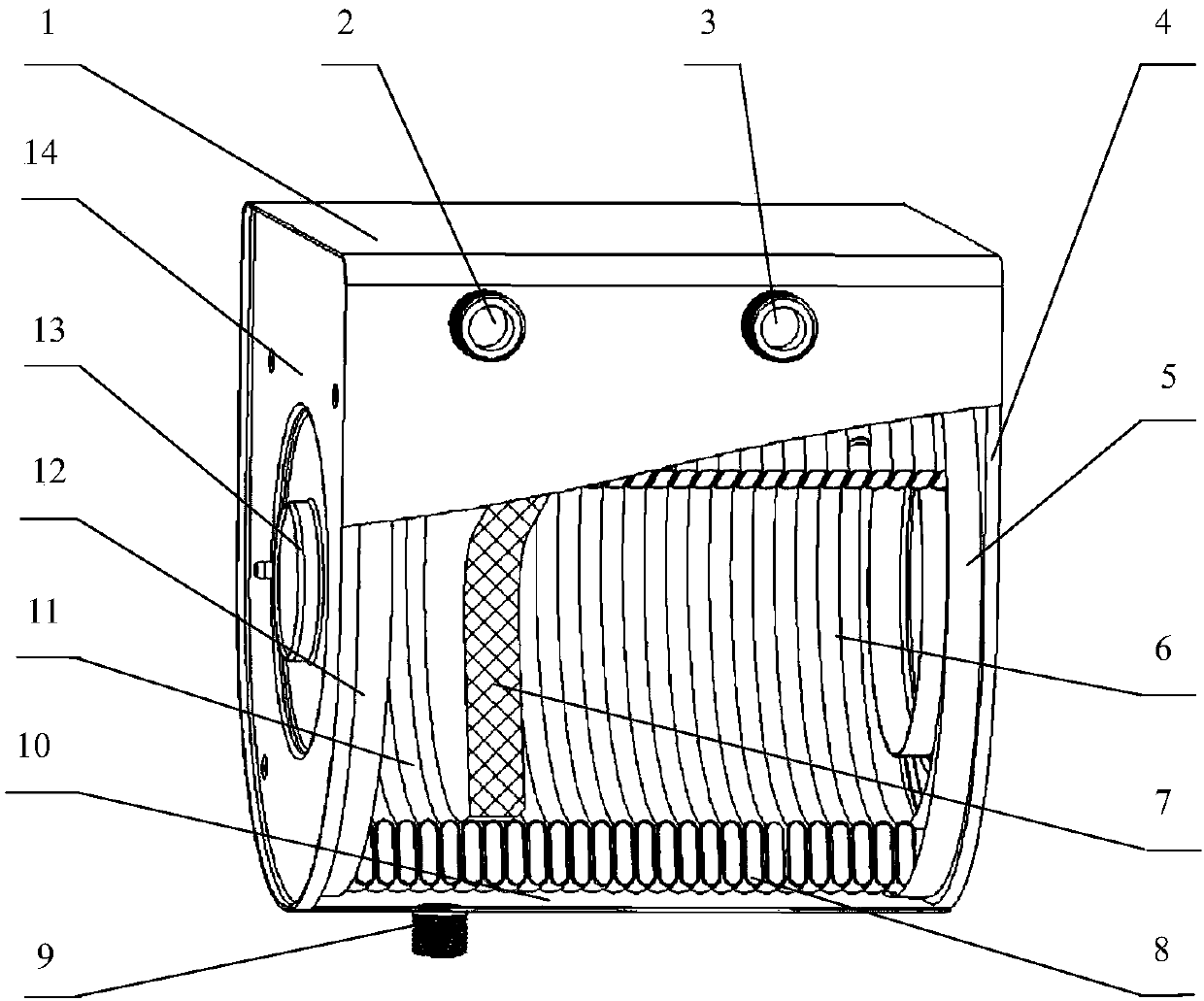

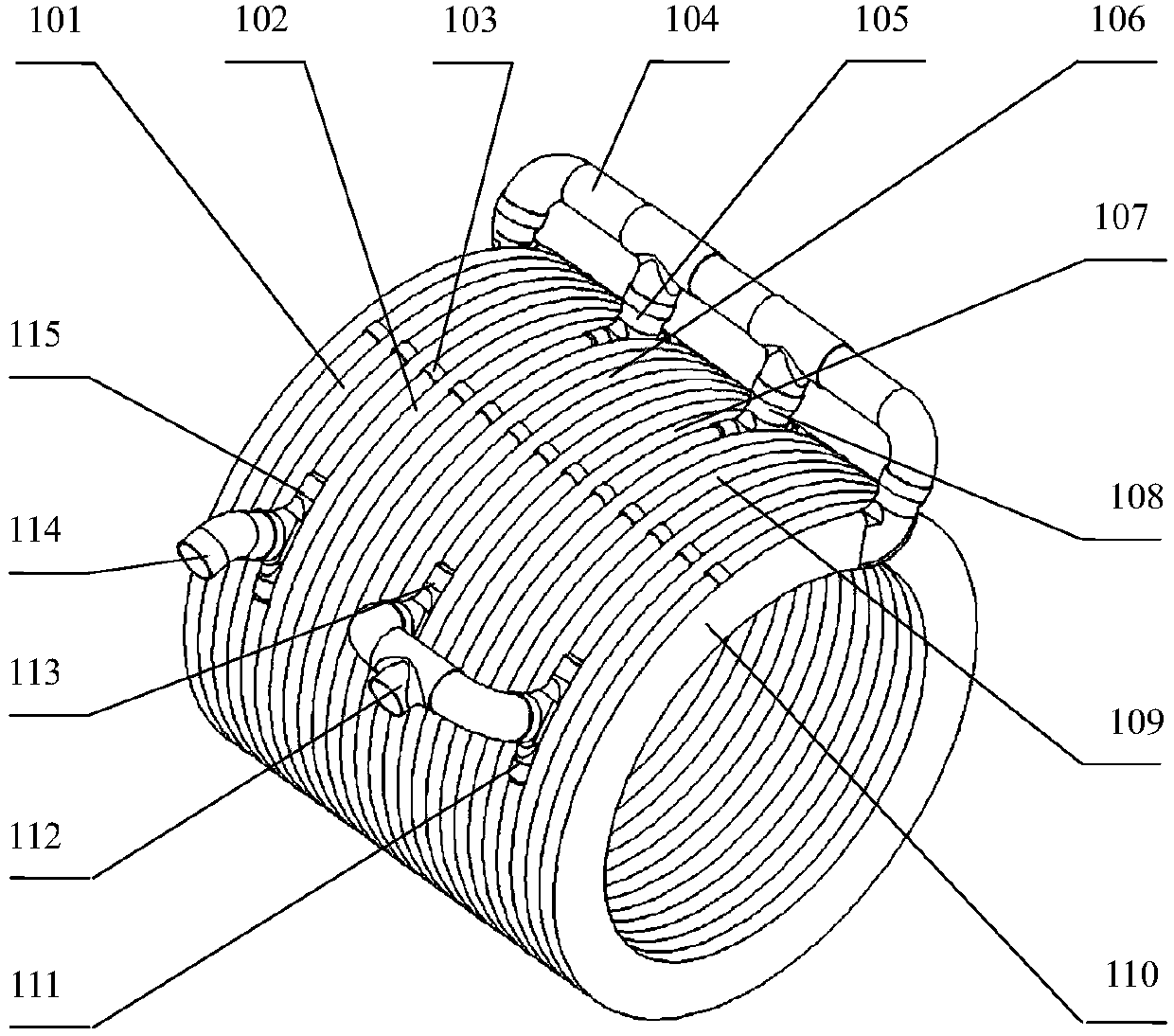

[0026] like figure 1 , 2 As shown, a heat exchanger structure is composed of a shell 1 and an annular coil group 8. The shell 1 has a water inlet 2, a water outlet 3, a condensed water outlet 9 at the bottom, and a rear end cover on the upper side of the shell 1. 14 and the front end cover 4, the rear end cover 14 has an exhaust port 13 and a rear positioning ring 12, the front end cover 4 has a front positioning ring 5, and the annular coil group 8 is fixed inside the housing 1 Between the rear positioning ring 12 and the front positioning ring 5, a spacer cavity 10 is formed between the annular coil group 8 and the housing 1, and a port of the diversion port 114 is connected to the inlet The water outlet 2 is welded together, a port of the confluence port 112 is welded together with the water outlet 3, a heat shield 7 is fixed in the inner cavity of the annular coil group 8, and the inner cavity is divided into a condensation chamber 11 and a In the combustion chamber 6, t...

Embodiment 2

[0031] refer to Figure 5 , provides a schematic diagram of another specific embodiment of the annular coil group in a heat exchanger structure of the present invention, the annular coil group 8 has a long helical tube 301, and the long helical tube 301 is opened Several holes, welding pipe I302, pipe II303, pipe III304, pipe IV305, pipe V306 are welded on the holes, and the connecting pipe 104 is used to connect the first and last ports of the long spiral pipe 301 with the pipe I302, The welded pipe II303 is welded together, the welded pipe III304 and the welded pipe IV305 are welded together by the confluence port 112, the diversion port 114 is welded on the welded pipe V306, and several gap pieces 103 are used for welding On the tube wall of the long helical tube 301, the helical gap is kept the same.

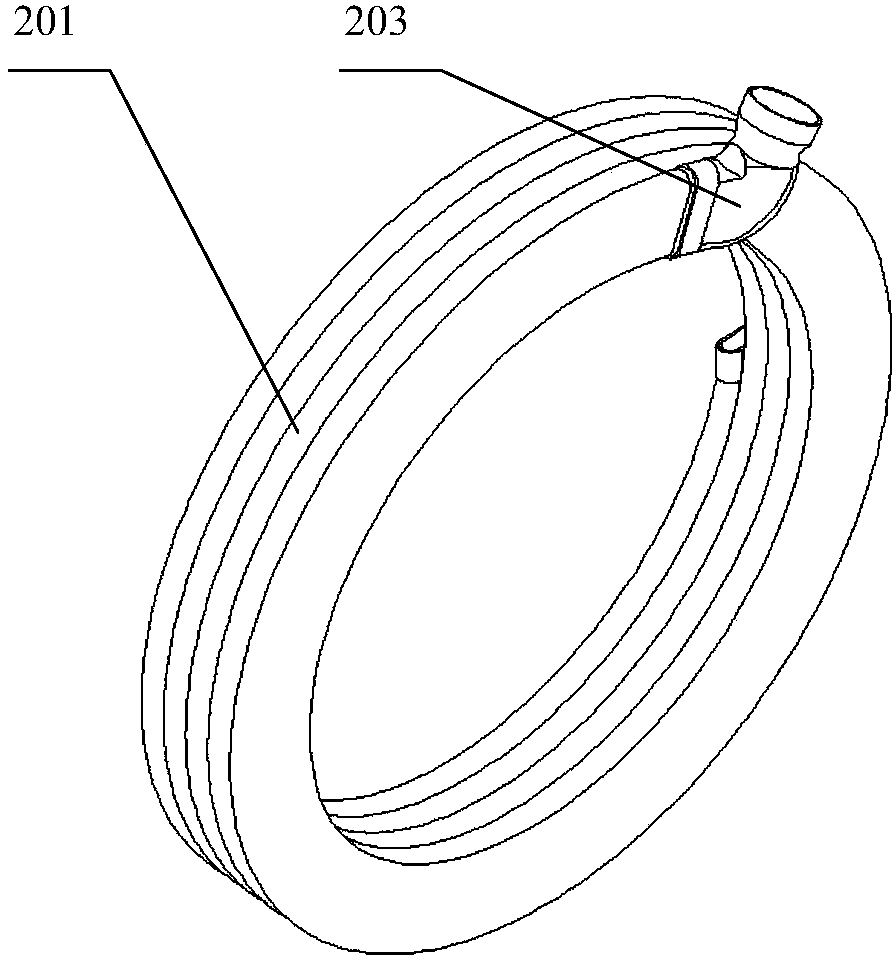

[0032] refer to Image 6 , shows a schematic diagram of a long spiral tube 301 in a heat exchanger structure of this embodiment, and the long spiral tube 301 is welded wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com