Production process for full-sealing automatic production line for fluid sealant for construction

An automatic production line and production method technology, applied in chemical instruments and methods, adhesives, sustainable manufacturing/processing, etc., can solve the problems of increased cost, low production efficiency, large glue loss, etc. , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

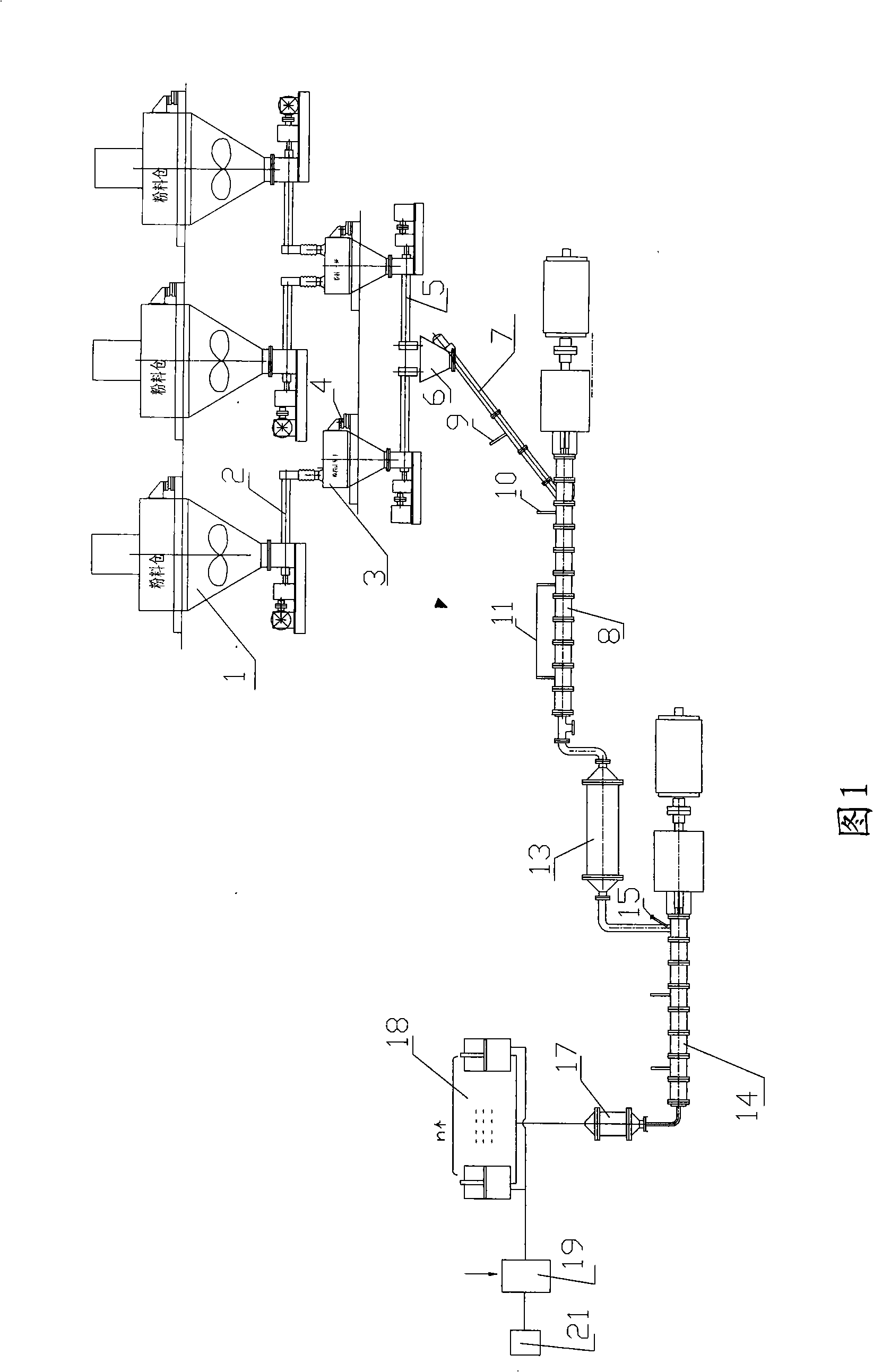

[0028] The invention discloses a production method of a fully sealed automatic production line of sealant for construction. The automatic production line mainly consists of a high-position powder hopper 1, a screw machine 2, 5, a measuring hopper 3, a weightless electronic scale 4, a hopper 6, and a building block type forced feeding Machine 7, building block type main screw machine 8, base glue 9, 10 and emptying port 11, precision high-viscosity pump 12, tube-and-tube high-efficiency heat exchanger 13, high-efficiency heat exchanger 17, multi-station material pressure accumulator 18 and packing machine equipment 21;

[0029] As shown in Figure 1, the production method of the fully-sealed automatic production line for building sealant is: it mainly includes feeding, feeding, material dispersion and mixing, cooling and cooling, adding additives, discharging by-products, buffer storage, mixing with color paste and separation. Install and other steps.

[0030] 1. Three high-lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com