Low-temperature-resistant silicone sealant and preparing method thereof

A silicone and sealant technology, applied in the field of sealants, can solve problems such as unsatisfactory low temperature resistance, and achieve the effects of reducing low temperature cracking, improving mechanical properties, and improving low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

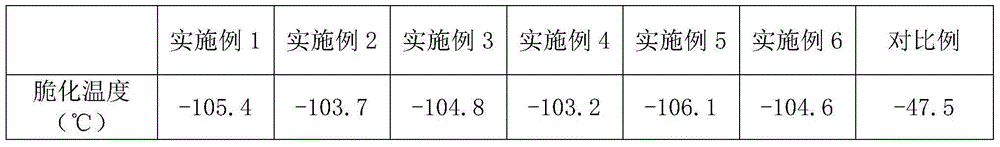

Examples

Embodiment 1

[0026] A low-temperature resistant silicone sealant, made of the following components in parts by weight: 100 parts of end-capped polydimethylsiloxane, 5 parts of phenyl silicone oil, 17 parts of fumed white carbon black, methyl trimethoxy 8 parts of base silane, 1.5 parts of dibutyltin dilaurate, 1 part of aminosilane coupling agent, 1.6 parts of calcium chloride, 1.7 parts of naphthylamine anti-aging agent, 2.5 parts of toluene diisocyanate, solubilizer PE-g-MAH4.8 Parts, polysulfone 11.5 parts, calcium carbonate hollow microspheres 14.7 parts.

[0027] The steps of its preparation method are as follows:

[0028] (1) Put the dried calcium carbonate hollow microspheres into absolute ethanol, ultrasonically disperse for 40 minutes, heat to 85°C and stir for 12 minutes, add the aqueous solution of aminosilane coupling agent, heat up to 95°C, and stir for 1 hour Finally, take it out, wash it with absolute ethanol for 5 times, and then place it in a vacuum drying oven and dry it...

Embodiment 2

[0032] A low-temperature resistant silicone sealant, made of the following components in parts by weight: 100 parts of end-capped polydimethylsiloxane, 8 parts of phenyl silicone oil, 19 parts of silicon micropowder, methyltrimethoxysilane 9 parts, 1.8 parts of dibutyltin dilaurate, 0.7 parts of aminosilane coupling agent, 1.4 parts of calcium chloride, 1.9 parts of naphthylamine antioxidant, 4 parts of toluene diisocyanate, 4 parts of solubilizer PE-g-MAH, polysulfone 12 parts, 14.4 parts of calcium carbonate hollow microspheres.

[0033] The steps of its preparation method are as follows:

[0034] (1) Put the dried calcium carbonate hollow microspheres into absolute ethanol, ultrasonically disperse for 40 minutes, heat to 85°C and stir for 12 minutes, add the aqueous solution of aminosilane coupling agent, heat up to 95°C, and stir for 1 hour Finally, take it out, wash it with absolute ethanol for 5 times, and then place it in a vacuum drying oven and dry it at 90° C. for 9...

Embodiment 3

[0038] A low-temperature resistant silicone sealant, made of the following components in parts by weight: 100 parts of end-capped polydimethylsiloxane, 10 parts of phenyl silicone oil, 20 parts of silicon micropowder, methyltrimethoxysilane 3 parts, 1.4 parts of dibutyltin dilaurate, 0.9 parts of aminosilane coupling agent, 1 part of calcium chloride, 1.6 parts of naphthylamine antioxidant, 3 parts of toluene diisocyanate, 4.2 parts of solubilizer PE-g-MAH, 11 parts of polysulfone, 14 parts of calcium carbonate hollow microspheres.

[0039] The steps of its preparation method are as follows:

[0040] (1) Put the dried calcium carbonate hollow microspheres into absolute ethanol, ultrasonically disperse for 40 minutes, heat to 85°C and stir for 12 minutes, add the aqueous solution of aminosilane coupling agent, heat up to 95°C, and stir for 1 hour Finally, take it out, wash it with absolute ethanol for 5 times, and then place it in a vacuum drying oven and dry it at 90° C. for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com