Insulated layer and sheath material of charging pile connecting cable and preparation method for insulated layer and sheath material

A sheath material, a technology for connecting cables, applied in the directions of insulators, insulated conductors, insulated cables, etc., can solve problems such as poor low temperature resistance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

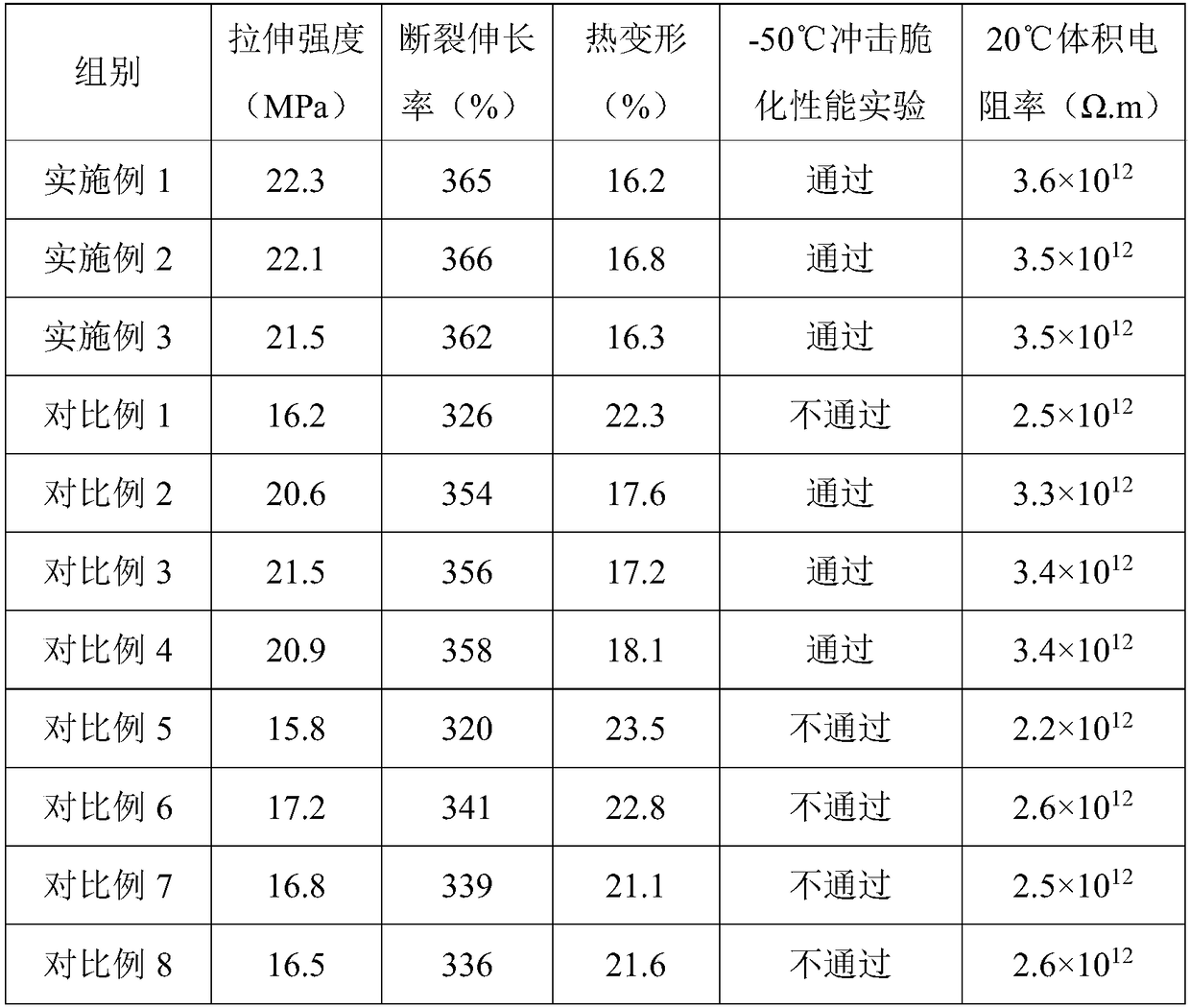

Examples

preparation example Construction

[0025]The preparation method of the insulating layer and the sheath material of the charging pile connecting cable comprises the following steps:

[0026] S1: Add polyvinyl chloride resin, ethylene vinyl acetate copolymer, hydrogenated nitrile rubber, acrylate rubber, and cross-linking agent into the mixer and stir evenly, then add accelerator, anti-aging agent, and plasticizer, and heat up to 70- Mix at 80°C for 6-10 minutes to obtain mixed material A; the stirring speed of the mixer is 200-500r / min;

[0027] S2: Add anti-scorch agent, stabilizer, polymer compatibilizer, coupling agent, naphthenic oil, polychlorotrifluoroethylene, polyethylene wax to the mixed material A in step S1, then heat up to 90-110°C, mix 6-8min, to obtain the mixed material B;

[0028] S3: Put the mixed material B in step S2 into a twin-screw extruder to granulate at a processing temperature of 150-180° C. to obtain insulation layer and sheath material for cables.

Embodiment 1

[0030] An insulation layer and sheath material for a charging pile connection cable, in parts by weight, including the following raw materials: 40 parts of polyvinyl chloride resin, 45 parts of ethylene vinyl acetate copolymer, 13 parts of hydrogenated nitrile rubber, and 12 parts of acrylic rubber part, 0.1 part of crosslinking agent, 0.3 part of flame retardant, 0.2 part of anti-scorch agent, 0.3 part of accelerator, 0.2 part of antioxidant, 0.2 part of anti-aging agent, 0.5 part of plasticizer, 0.2 part of stabilizer, polymer phase 0.4 parts of solvent, 0.3 parts of coupling agent, 0.3 parts of naphthenic oil, 0.5 parts of polychlorotrifluoroethylene, and 0.2 parts of polyethylene wax.

[0031] The cross-linking agent is triallyl cyanurate; the flame retardant is a mixture of red phosphorus and aluminum hydroxide; the anti-scorch agent is N-cyclohexylthiophthalimide; The accelerator is dipentamethylenethiuram tetrasulfide; the antioxidant is propylene pentaerythritol ester;...

Embodiment 2

[0037] An insulation layer and sheath material for a charging pile connection cable, in parts by weight, including the following raw materials: 30 parts of polyvinyl chloride resin, 40 parts of ethylene vinyl acetate copolymer, 15 parts of hydrogenated nitrile rubber, and 11 parts of acrylic rubber part, 0.3 part of crosslinking agent, 0.2 part of flame retardant, 0.4 part of anti-scorch agent, 0.2 part of accelerator, 0.2 part of antioxidant, 0.5 part of anti-aging agent, 0.4 part of plasticizer, 0.1 part of stabilizer, polymer phase 0.6 parts of solvent, 0.2 parts of coupling agent, 0.2 parts of naphthenic oil, 0.3 parts of polychlorotrifluoroethylene, and 0.1 parts of polyethylene wax.

[0038] The cross-linking agent is triallyl cyanurate; the flame retardant is a mixture of red phosphorus and aluminum hydroxide; the anti-scorch agent is N-cyclohexylthiophthalimide; The accelerator is dipentamethylene thiuram tetrasulfide; the antioxidant is stearyl propionate; the antioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com