Hot melt adhesive, preparation method and application of hot melt adhesive, and heat shrinkable sleeve

A technology of hot melt adhesive and melt index, which is applied in the direction of adhesives, heat-activated films/sheets, adhesive types, etc., can solve the problems of narrow application range, low temperature resistance, poor bonding performance of hot melt adhesives, etc., and achieve operation Simple, low cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0170] According to a second aspect of the present invention, a kind of preparation method of hot melt adhesive is provided, comprising the following steps:

[0171] Measure asphalt mastic, thermoplastic resin, tackifying resin, optional antioxidant and optional filler according to the formula, heat and knead, cool and shape to obtain the product.

[0172] According to the formula, take the finished product of asphalt horseshoe grease or the raw materials of the asphalt horseshoe grease, mix with thermoplastic resin, tackifying resin, optional antioxidant and filler, and then shape it.

[0173] Mixing can be completed in one step, or different components can be added in sequence to carry out mixing step by step, for example: after mixing other components except tackifying resin for a certain period of time, add tackifying resin and mix to the greatest extent. Activates the tack of the hot melt adhesive.

[0174] The preparation method of the hot melt adhesive of the present i...

Embodiment 1-3

[0194] The formula of embodiment 1-3 is as table 1, and preparation method is identical, is:

[0195] According to the formula, take the raw materials of S glue (asphalt mastic), mix with thermoplastic resin (PE, EVA(I), EVA(II)), tackifying resin (phenolic resin (I)), and mix at 140°C for 8 minutes Left and right, the stirring speed is 60rpm, cooling, forming, and the hot melt adhesive of Example 1-3 is obtained.

[0196] Table 1

[0197] The weight percentage of each ingredient, %

Example 1

Example 2

Example 3

S glue

40

59

50

PE

12

10

10

EVA(I)

30

20

0

EVA(II)

0

0

30

Phenolic resin (I)

18

11

10

[0198] Composite the hot-melt adhesive obtained in Examples 1-3 with a substrate (for example, PE, cross-linked PE, etc.) to obtain a heat-shrinkable sleeve and / or a heat-shrinkable tape.

[0199] The performance of embodiment 1-3 hot-melt adhesive (the adhesive layer performa...

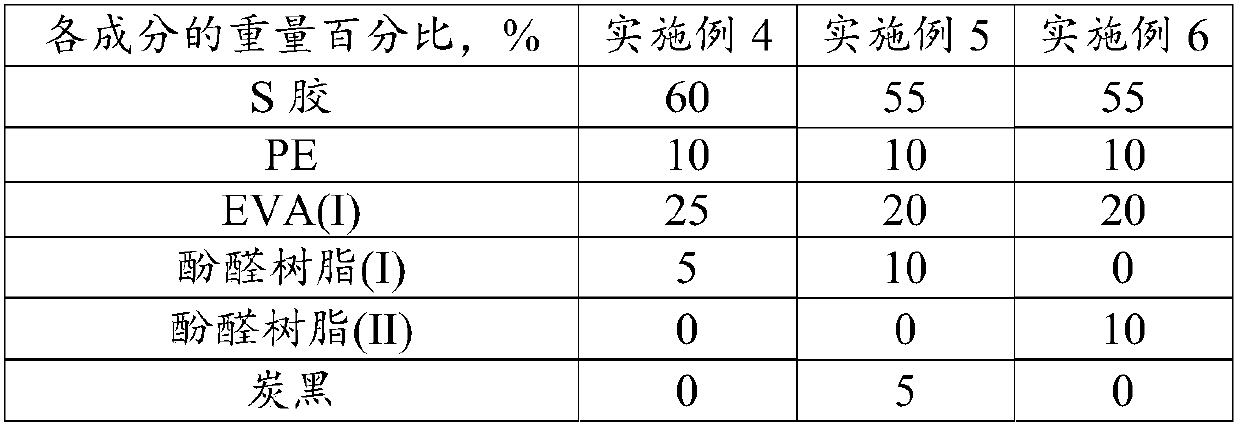

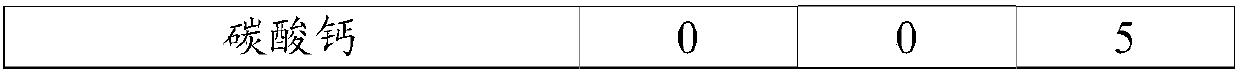

Embodiment 4-6

[0206] The formula of embodiment 4-6 is as table 3, and preparation method is identical, is:

[0207] According to the formula, take the raw materials of S glue, and thermoplastic resin (PE, EVA (I)), tackifying resin (phenolic resin (I), phenolic resin (II)), filler (carbon black, calcium carbonate), at 140 ℃ mixing for about 8 minutes, the stirring speed is 60rpm, cooling and molding, and the hot melt adhesive of Example 4-6 is obtained.

[0208] table 3

[0209]

[0210]

[0211] The heat-shrinkable sleeve and / or heat-shrinkable tape of the present invention can be obtained by compounding the hot-melt adhesive obtained in Examples 4-6 with a substrate (for example, PE, cross-linked PE, etc.).

[0212] The test result (test method is the same as embodiment 1-3) of embodiment 4-6 is shown in table 4.

[0213] Table 4

[0214] Performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com