Construction method of sewage pipeline

A construction method and technology of sewage pipelines, applied in the field of pipelines, can solve the problems of low efficiency of sewage pipelines, etc., and achieve the effects of improving construction efficiency, improving compressive strength, and improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

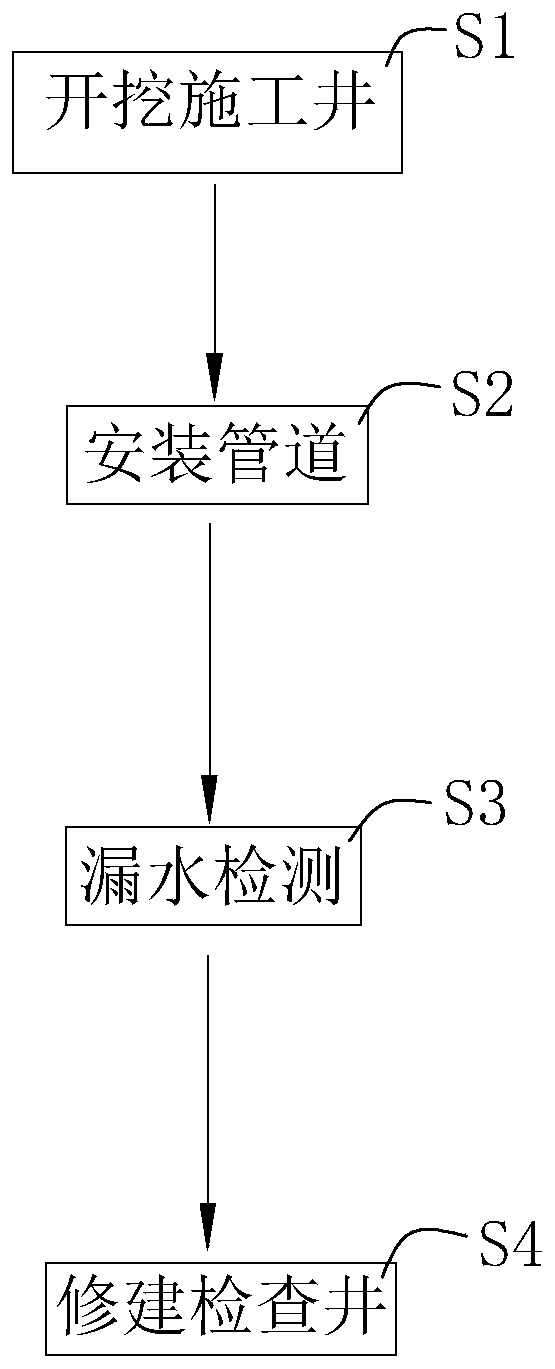

[0050] A kind of sewage pipeline construction method, with reference to figure 1 , including the following steps:

[0051] S1. Excavation of construction wells, details are as follows:

[0052] Position according to the position of the inspection well in the design drawings, and excavate the construction well, and start the next step after excavating at least two adjacent construction wells.

[0053] S2. Install the pipeline, as follows:

[0054] Drill the hole with the drilling rig, excavate the soil with the excavator and transport the soil damaged by the drilling rig out of the hole in time to drill the sewage pipe installation hole on the side wall of the construction well and remove the excavated soil in time;

[0055] The inner diameter of the sewage pipe installation hole is 10mm larger than the inner diameter of the sewage pipe in the design. After drilling for 1m, clean the inner wall of the pipe and spray the sewage pipe composition to form the pipe wall of the sew...

Embodiment 2

[0063] The difference from Example 1 is that

[0064] In step S2:

[0065] The inner diameter of the sewage pipe installation hole is 15mm larger than the inner diameter of the sewage pipe in the design. After drilling for 2.5m, clean the inner wall of the pipe and spray the sewage pipe composition to form the pipe wall of the sewage pipe;

[0066]When spraying, first add the sewage pipe composition into the extrusion equipment and heat it to 240°C, then extrude and spray on the inner wall of the sewage pipe installation hole through the nozzle, and the spray thickness is 15mm;

Embodiment 3

[0068] The difference from Example 1 is that

[0069] In step S2:

[0070] The inner diameter of the sewage pipe installation hole is 18mm larger than the inner diameter of the sewage pipe in the design. After drilling for 5m, clean the inner wall of the pipe and spray the sewage pipe composition to form the pipe wall of the sewage pipe;

[0071] When spraying, first add the sewage pipe composition into the extrusion equipment and heat it to 260°C, then extrude and spray on the inner wall of the sewage pipe installation hole through the nozzle, and the spray thickness is 18mm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com