Low temperature resistant EPDM (ethylene-propylene-diene monomer) cable material and preparation method thereof

An EPDM100, low temperature resistance technology, applied in the field of EPDM cable material, can solve the problems of performance decline and low temperature resistance, and achieve the effect of reducing embrittlement temperature, improving low temperature resistance and improving low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

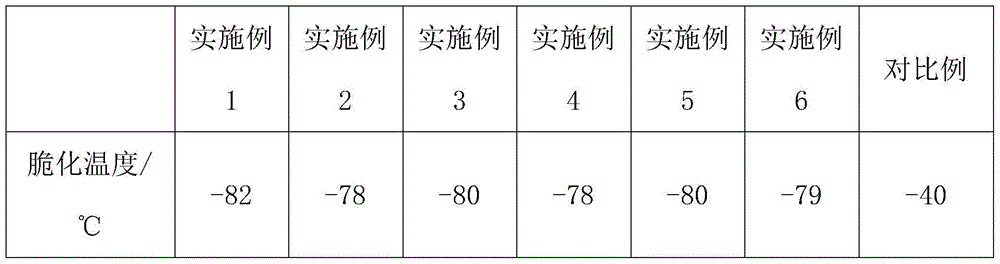

Examples

Embodiment 1

[0024] Low temperature resistant EPDM cable material, its composition in parts by weight is: 100 parts of EPDM, 9 parts of ECO rubber, 4.5 parts of MMA, 0.5 parts of peroxyketal, 11 parts of EVA, 4 parts of EPDM-g-MAH, 3.5 parts of DTDM, 1.8 parts of TAIC parts, 84 parts of talcum powder, 0.1 parts of KH5500, and 1.5 parts of antioxidant MB.

[0025] The steps of its preparation method are as follows:

[0026] (1) Add EPDM, MAH, and DCP to a high-speed kneader and mix for 10 minutes, then transfer to a twin-screw extruder for melt extrusion. The temperature is 170°C, the extruded pellets are dried and dissolved in xylene, refluxed at 60°C for 2 hours, cooled and filtered, the filter cake is washed with ethanol for 3 times and then dried in a vacuum oven at 90°C for 3 hours , get compatibilizer;

[0027] (2) According to the formula, add the compatibilizer obtained in step (1) and other components except DTDM and TAIC into the internal mixer at 100°C for 12 minutes to obtain ...

Embodiment 2

[0029] Low temperature resistant EPDM cable material, its composition in parts by weight is: 100 parts of EPDM, 12 parts of ECO rubber, 4.2 parts of MMA, 0.3 parts of peroxyketal, 12 parts of EVA, 3 parts of EPDM-g-MAH, 4 parts of DTDM, 2.5 parts of TAIC parts, calcined kaolin 85 parts, KH5500.1 parts, antioxidant MB 1.8 parts.

[0030] Its preparation method is the same as Example 1.

Embodiment 3

[0032] Low temperature resistant EPDM cable material, its composition in parts by weight is: 100 parts of EPDM, 11 parts of ECO rubber, 4.8 parts of MMA, 0.3 parts of peroxyketal, 9.5 parts of EVA, 7 parts of EPDM-g-MAH, 2.5 parts of DTDM, 2 parts of TAIC parts, calcined kaolin 75 parts, KH5500.2 parts, antioxidant MB 1.4 parts.

[0033] Its preparation method is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com