Piezofan and heat sink system for enhanced heat transfer

a technology of enhanced heat transfer and heat sink, which is applied in the direction of machines/engines, positive displacement liquid engines, lighting and heating apparatus, etc., can solve the problem that the u.s. patent no. 4,498,851 does not provide any teaching on directing air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

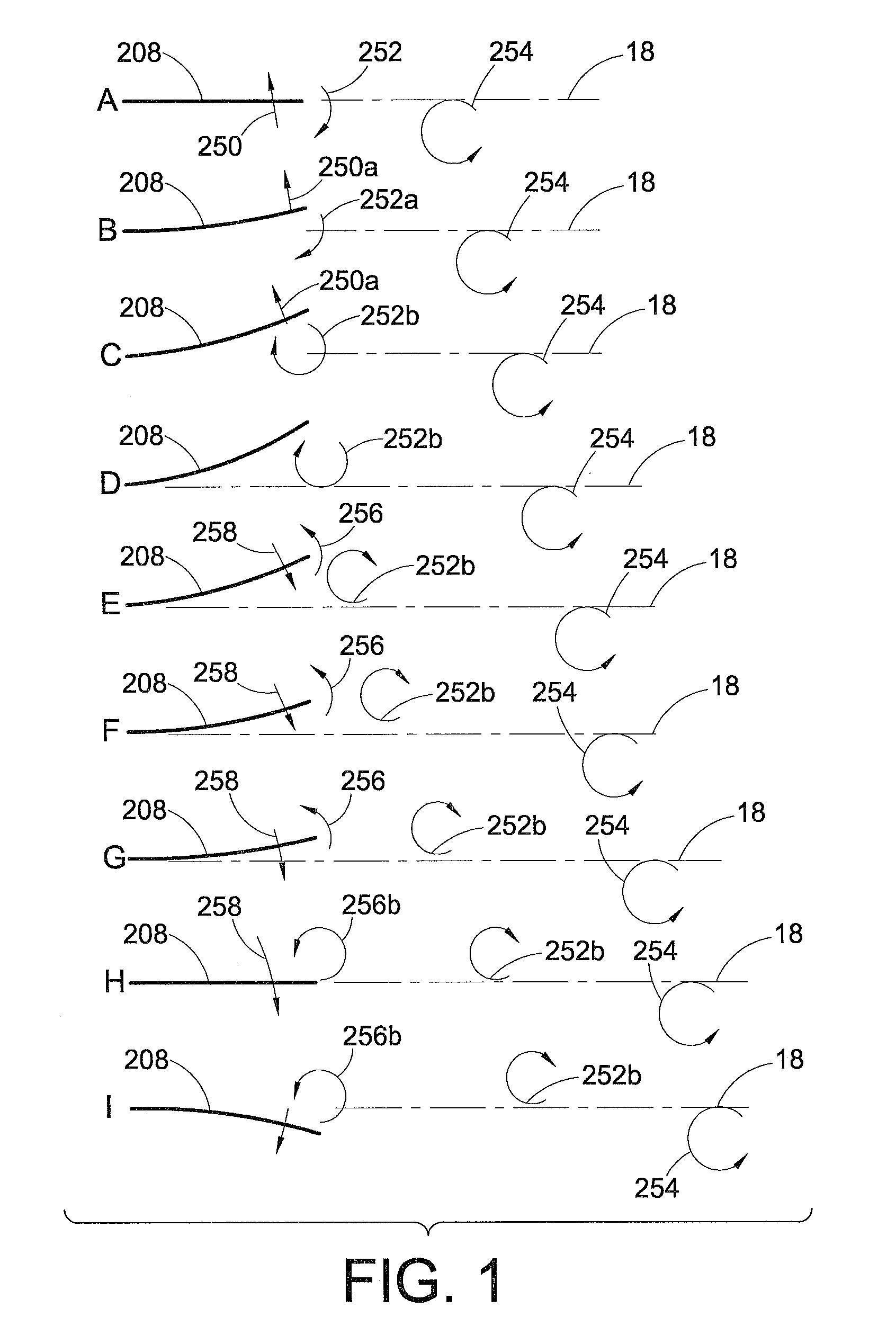

[0015]FIGS. 2A-2D depict a blade 30 of a piezoelectric fan disposed in a channel 32 defined by a first side wall 34, a second side wall 36 and a base wall (not numbered) that the side walls extend upwardly from. The blade is driven by a piezoelectric element (not shown), which will be described later. In FIG. 2A, the blade 30 of the piezoelectric fan is centered and moving upward as indicated by arrow 42, and air is being sucked toward the second wall 36 around the blade tip as indicated by arrow 44. The blade 30 nears its maximum stroke of its travel in FIG. 2B, leaving a nearly fully formed vortex 44a in its wake. The blade 30 then starts downwardly again in FIG. 2C as indicated by arrow 46. A fully formed vortex 44c is compressed against a constriction (formed by a constrictive member 48 extending into the channel 32 from the second side wall 36) and is expelled from an outlet 52 of the channel as seen in FIG. 2D as the blade 30 continues to move toward the second side wall 36. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com