Method for vacuum pressure and temperature varying coupling adsorbing and trapping carbon dioxide in flue gas

A carbon dioxide and flue gas technology, applied in chemical instruments and methods, through adsorption, separation methods, etc., can solve the problems of high cost of adsorption and capture, high energy consumption, low purity, and rising costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

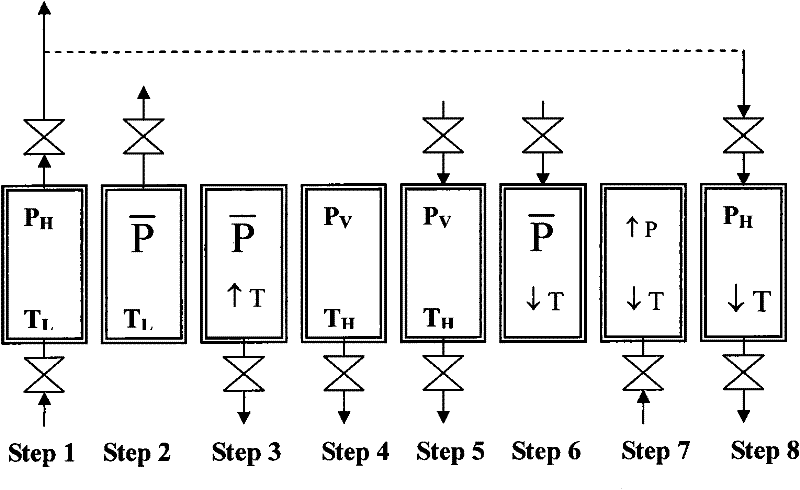

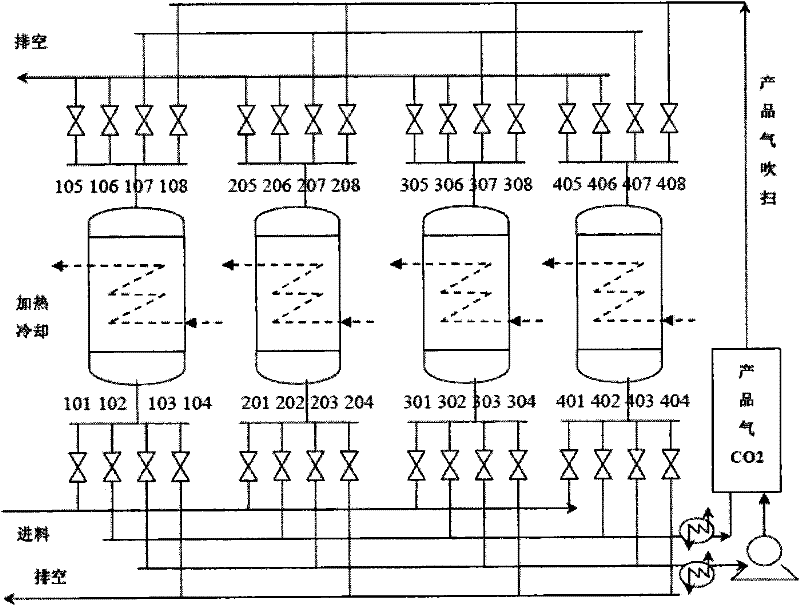

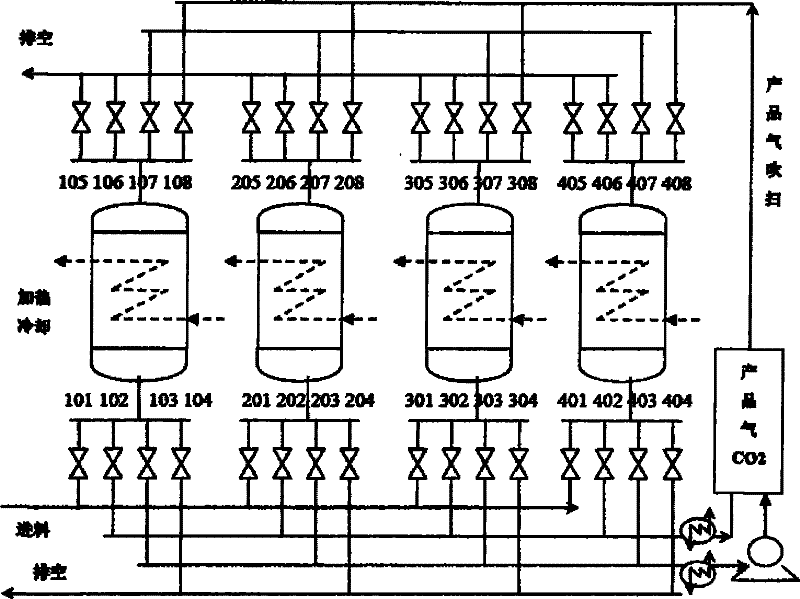

[0043] Experimental example of adsorption of carbon dioxide in flue gas by vacuum variable pressure variable temperature coupling process, single column experiment, including adsorption, heating, vacuuming, vacuum purging, and cooling cycle to capture CO 2 step. 116 grams of 13X APGIIA zeolite was packed into a stainless steel tube with an inner diameter of 25 mm to a packing height of 350 mm. The 13X-APGIIA zeolite adsorbent was purchased from Shanghai Global Molecular Sieve Co., Ltd., with a pore size of 10A and a particle size of about 2.0mm. The adsorber is designed as a jacket, the inner tube is filled with adsorbent, and the jacket is connected with heat transfer oil to heat and cool the adsorbent in the adsorber. The temperature of the circulating heat transfer oil is controlled by a high and low temperature constant temperature bath.

[0044] Simulated flue gas (15% CO 2 and 85%N 2 ) enters the adsorption tower from the bottom of the tower at nearly normal pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com